The Chongqing (China) is rich in barite-fluorite associated ore resources. These ores are characterized by a strong intergrowth between barite and fluorite, making their separation challenging. Barite and fluorite are often found intertwined, as aggregates, or even as inclusions within one another. Some gangue minerals, such as calcite and quartz, further complicate the process of achieving high-purity products.

When faced with this type of ore, our preferred method involves a sequential process of “gravity-flotation separation”. This approach achieves efficient separation and delivers notable economic returns.

1. Raw Ore Properties and Analysis

1.1 Mineral Composition

The ore primarily consists of barite (53.12%) and fluorite (30.24%), with gangue minerals such as calcite, quartz, and minor amounts of potassium feldspar and hematite. Liberation analysis showed that barite and fluorite have high individual liberation rates, at 84.43% and 85.06% respectively. The high liberation degree supports effective separation during processing.

1.2 Particle Size and Density Distribution

Fluorite particles are generally in the range of 20–300 µm, with some as large as 425 µm. They are high-purity calcium fluoride minerals with good cleavage. Barite is denser, with density peaks at 3.1–3.2 g/cm³ and 4.4–4.5 g/cm³. Based on these properties, gravity separation is well-suited for initial processing, while flotation can be used to refine the fluorite concentrate.

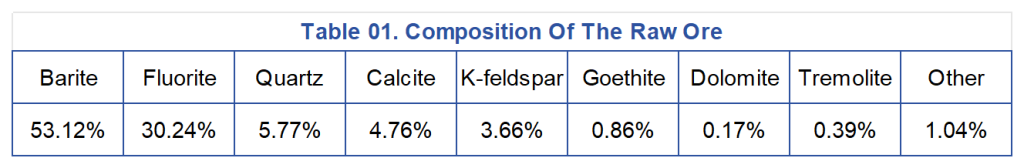

2. Mineral Processing Flow Design

A combined gravity and flotation process was developed to maximize recovery and product purity. Gravity separation was used to recover barite and pre-concentrate fluorite, while flotation was applied to upgrade fluorite to a higher grade.

2.1 Gravity Separation

Particle Size Classification and Equipment

The ore was divided into two size fractions: coarse (-5+0.45 mm) and fine (-0.45 mm). Coarse particles were processed using a jig, and fine particles were treated with a spiral chute. This approach leveraged the density difference between barite, fluorite, and gangue minerals for effective separation.

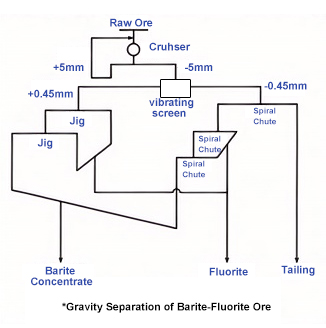

Gravity Separation Results

The gravity separation stage produced a barite concentrate with a grade of 93.44% and a recovery rate of 87.88%. A large portion of the gangue minerals was discarded at this stage, and fluorite was pre-concentrated effectively, providing a clean feed for the flotation stage.

3. Flotation for Fluorite Processing

After gravity separation, the fluorite pre-concentrate was ground further to improve liberation. Flotation was then used to separate fluorite from remaining gangue minerals. Fatty acid collectors were applied to target fluorite particles, while suppressants minimized interference from calcite and quartz.

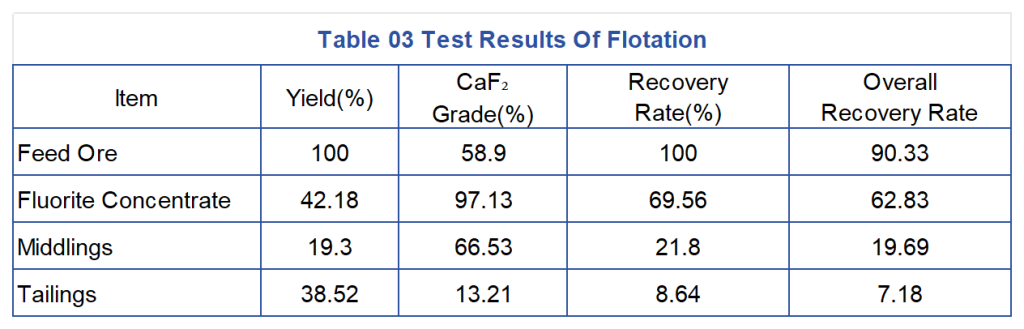

The results of the fluorite processing showed that the final fluorite concentrate had a grade of 97.13%, with a recovery rate of 69.56% in the flotation stage and an overall recovery rate of 62.83%. These results demonstrate the high efficiency of the combined process in fluorite processing.

4. Technical Features of the Gravity-Flotation Separation

Targeted Combination of Processes: The gravity-flotation process exploits the differences in density and surface properties between barite, fluorite, and gangue minerals. Gravity separation reduces the load on flotation by discarding gangue early, while flotation refines the fluorite product.

Optimized Equipment Use: The combination of jigs and spiral chutes achieved high barite recovery. Grinding and flotation were used to refine fluorite efficiently, ensuring high recovery rates during fluorite processing.

Efficient Use of Reagents: Fatty acid collectors and selective suppressants enhanced the flotation selectivity for fluorite processing, minimizing the loss of fluorite to tailings.

Balanced Cost and Efficiency: By reducing the material to be floated, the gravity stage lowers chemical and energy costs, making the process economically viable for large-scale fluorite processing.

5. Conclusion

The combined “gravity separation followed by flotation” process is highly effective for processing barite-fluorite associated ores in Chongqing. Gravity separation significantly improves barite recovery, while flotation efficiently upgrades fluorite to high purity. This process is both cost-effective and resource-efficient, ensuring high-quality products for the market.

What is the most efficient mineral processing line in your case? Find out the best solution with our experts. You can send emails to us.