Alluvial gold sluice boxes are widely used in placer gold concentrators. The method of beneficiation by means of the water flowing in the sluice box is called sluice box beneficiation. According to the size of the processed material, the sluice box can be divided into coarse-grained sluice box and slurry sluice box. According to the mechanization of the sluice box, it can be divided into fixed sluice box and mechanical sluice box.

(1) Fixed Coarse-grain Placer Gold Sluice Box

Fixed coarse-grain sluice box is widely used in placer gold concentrators. This kind of sluice box is divided into shallow filling sluice box and deep filling sluice box according to the operating system.

Shallow fill sluice box is generally used to process the materials that have been washed and screened, and the feed size is less than 16-24mm. The deep fill sluice box is generally used for materials that have not been washed and screened or have been coarsely classified, but the processed material has a large particle size and needs to be further washed and broken, and its feeding particle size can reach more than 100mm.

The deep fill sluice box is mainly used for land washing of placer gold mines. Compared with the shallow filling sluice box, the deep filling sluice box has a larger section depth and a narrower width. The groove depth is usually 0.3~1m, and the width is not less than 1.2 times the groove depth, but its length is longer, generally 20~100m. Therefore, it is more labor-intensive to clean the concentrate of the deep-filled sluice box. This kind of sluice box is rarely used now.

The coarse-grained sluice box for gold beneficiation is used as the roughing beneficiation equipment for low-grade placer gold ore. It has the advantages of large feed size range, simple structure, low investment, low production cost, no chemical pollution and large enrichment ratio. However, the mineral layer is easy to compact, the labor intensity is high, the working time is long, and the recovery rate is low, about 50% to 60%.

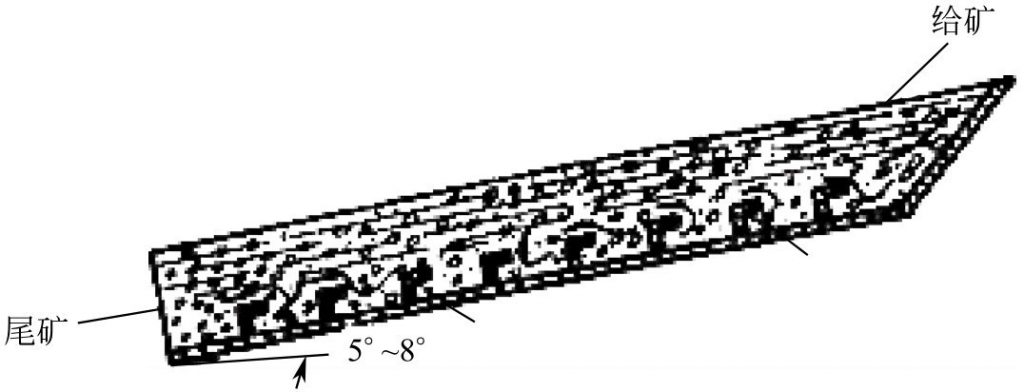

The structure of the coarse-grained sluice box is shown in Figure 3-3. The trough is a long trough made of steel plate or wood, with a length of more than 4m, a width of 0.4-0.6m, and a height of 0.3-0.5m. There are steel or wooden horizontal or grid-shaped baffles at the bottom of the tank, and horizontal baffles made of angle steel (50mm×50mm) are installed every 0.4m at the bottom of the tank. Some also put a layer of rough pavement under the baffle, such as reed mats, blankets, felt, plush cloth, etc. The installation slope of the groove is generally 5°~8°.

The slurry is fed from the high end and flows in a fast turbulent flow in the tank. The vortex’s revolving motion continuously transfers dense gold particles and other heavy minerals to the bottom layer, forming a heavy mineral layer which is blocked by the baffle and stays in the tank. Light minerals are pushed by the water flow and discharged out of the tank. After a period of time when there is a lot of concentrate at the bottom of the tank, stop feeding the ore, add water to clean, then remove the baffle for washing, and finally flush out the bottom concentrate. If there is a pavement, the pavement shall be cleaned, and the washed product shall be incorporated into the concentrate.

(2) Pavement Sluice Box

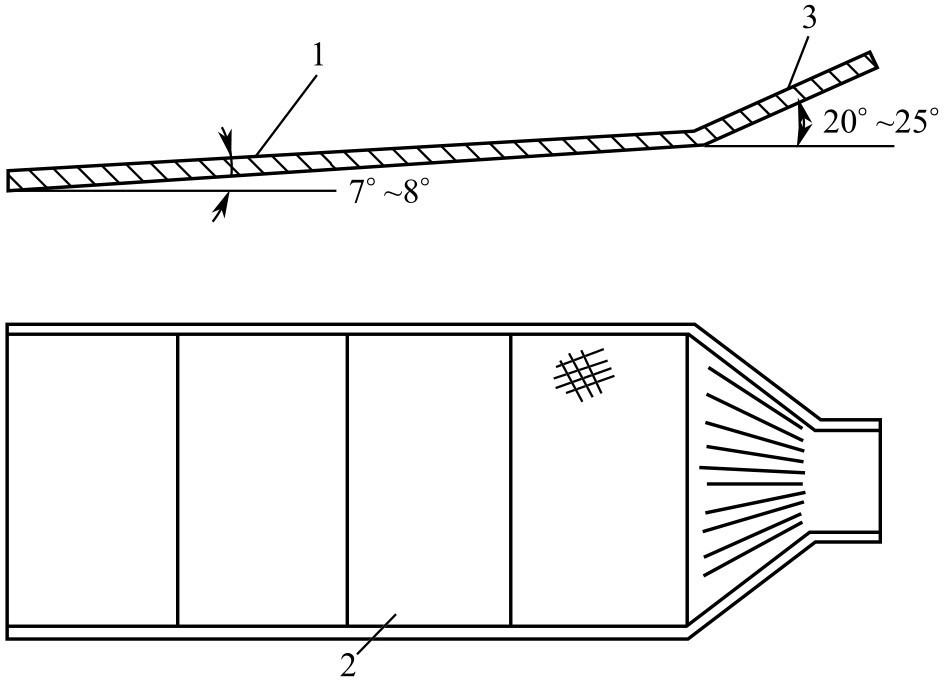

The structure of the pavement (cloth) sluice box is shown in Figure 3-4, which can be made of wood or iron plate. The groove width is 1~1.5m and the length is 2~3m. The head is equipped with a dividing plate for distributing mineral pulp, and there is no baffle on the bottom of the tank. Rough surface cotton flannel, woolen blanket, cotton blanket, nylon blanket, etc. are used for paving. When working, the slope of the groove surface is 7°~8°, and the angle of the split plate is 20°~25°. The processed particle size when concentrating gold is less than 1mm. It can be used to treat amalgamation or flotation tailings. The ore concentration is 8%-15%.

The working mode of the pavement sluice box is intermittent. The slurry is fed from the upper part of the homogenizing dividing plate into the bottom of the tank to form a uniform flow layer, heavy minerals are deposited on the surface of the tank, and light minerals are discharged with the slurry flow. When the sediment has accumulated to a certain amount (for example, after a shift or several shifts), stop feeding the mine, take out the spreading cloth, and recover heavy minerals in the container. Then spread the cloth and proceed to the next cycle of work.

(3) Mechanically Movable Rubber-coated Sluice Box

The movable rubber-coated sluice box is generally referred to as a tape sluice box. Its structure is similar to a belt conveyor, but the tape is specially made with wavy ribs and horizontal ribs. The belt sluice box can be operated continuously, thereby avoiding the cleaning work, and overcoming the shortcomings of serious compaction of the mineral layer in the fixed sluice box, and improving the gold recovery rate.

(4) Vibrating Alluvial Gold Sluice Box

The vibrating sluice box is mainly used for placer gold beneficiation. Its shape is basically similar to that of a fixed sluice box, with a horizontal rib made of angle steel. The bottom of the groove is a rubber plate, and a bracket and a transmission mechanism are arranged under the rubber plate.

When working, the bracket makes an up and down alternate movement to push the rubber between the slides to move up and down, similar to the diaphragm of a jig concentrator. The mineral layer becomes loose when it rises, and it sucks when it falls, which makes the light and heavy minerals stratify and avoids the compression of the bed. , Improve the gold recovery rate. The equipment has the advantages of simple operation, high enrichment ratio, and high gold recovery rate.

(5) Combined Gold Sluice Box

A combined sluice box is a mineral processing equipment that combines two or more sluice boxes and sieve plates into one. Typical combined sluice boxes include Rose sluice box and Pearson sluice box.

The Ross sluice box consists of a feed box, a sieve plate, a water distribution pipe, a water gun and three parallel sluice boxes. Its characteristic is that the raw ore can be screened and washed on the same equipment. After the raw ore is screened by the sieve plate, the coarse product on the sieve and the fine product under the sieve are separated by different sluice boxes. The Ross sluice box has the advantages of simple structure, large processing capacity, and convenient movement. When dealing with placer with a lot of mud, the recovery rate of gold will be significantly reduced due to the poor processing effect.

(6) Slurry Alluvial Gold Sluice Box

There are many types of slurry sluice box. The fixed type includes soft-covered sluice box, evenly divided sluice box, round sluice box, etc.; mechanical transmission type includes belt sluice box, multi-layer automatic sluice box, rocking bed turning, and cross flow belt. sluice box, etc.

There are many types of slurry sluice boxes, the fixed ones include soft-covered sluice boxes, evenly divided sluice boxes, round sluice boxes, etc. Mechanical transmission types include belt sluice box, multi-layer automatic sluice box, rocking bed turning, and cross-flow belt sluice box.

The fixed soft-clad sluice box is the pretreatment of ground or fine-grained materials, and the feed size is usually less than 1mm. This kind of sluice box is not equipped with a rib, and a soft cover is laid on the bottom of the sluice box, such as linen cloth, blanket, nylon blanket, cotton flannel, patterned rubber sheet, etc., to retain heavy minerals. The pavement is determined according to the grain size of the ore. For processing coarser materials, the thickness of the water layer is 10~5mm, using coarser long-staple fabric or patterned rubber sheet. For processing fine-grain materials, when the thickness of the water layer is less than 5mm, fine-grained satin velvet fabric is used. Generally, the length of the soft-clad sluice box is 2~3m, the width is 1~1.5m, the installation inclination angle is 5°~20°, and the ore concentration is 15%~30%.

The structure of the soft-clad sluice box is simple, easy to manufacture, and simple to operate, but the production efficiency is low, intermittent operation, the pavement needs to be cleaned regularly, and the manual labor intensity is high. Therefore, the application of this sluice box is less.

References

Thank you for reading. What are your thoughts on Extract Gold by Sluice Box? Welcome to leave a message, or contact me directly:

- Email: asa.guo@foruimining.com

- Whatsapp & phone: +8618026978087

Gongyi Forui Machinery Factory, founded in 1986. We are one of the leading suppliers of gold wash plant equipment in Asia. Don’t hesitate to Contact Us, if you have any questions about beneficiation. And welcome to visit our company. Gongyi Forui Machinery Factory dedicated to serve you!