Sapphires, a kind of precious blue corundum, are prized for their captivating blue color and hardness. As natural sapphires are typically embedded within various minerals, an efficient process is required to wash them.

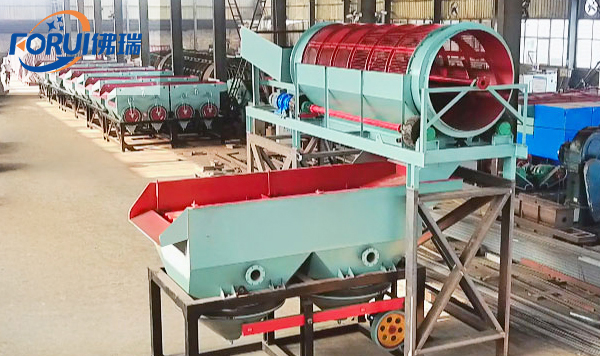

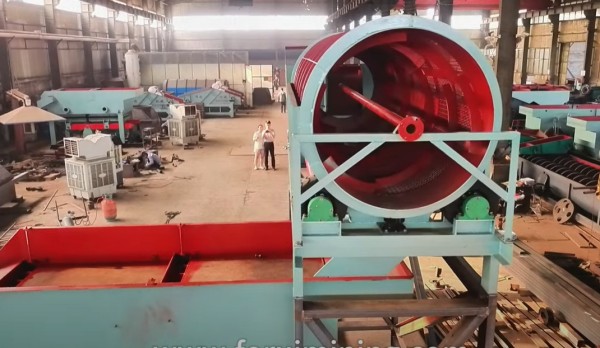

The sapphire washing line typically consists of feeders, washing machines, pulsator jigs, and dewatering screens.

Sapphire Washing Process

1. Cleaning and Screening

The raw ore is first processed through a rotary scrubber or trommel screen for cleaning and screening. This step effectively separates sapphire particles larger than 3mm and fine particles smaller than 3mm.

2. Gravity Separation

Depending on the size of the sapphires, they are processed in different machines. Coarse sapphire particles (3-50mm) are separated using a coarse pulsator jig. The -3mm fine sapphire particles is sent to a fine particle pulsator jig. The pulsator jigs utilize the pulsating flow of water to screen out the denser sapphire particles (3.95-4.10 g/cm³) from the sand and gravel.

3. Dewatering

The sapphire ore, after gravity separation, is processed through a dewatering screen to remove moisture, facilitating subsequent processing and use.

Advantages of the Sapphire Wash Plant

- Low Investment: Cost-effective equipment with an output of 20-60T/H and high recovery rates.

- Eco-Friendly: The process uses recycled water and operates without chemicals, ensuring no pollution.

- Versatile: Ideal for sapphires and other gemstones like rubies, diamonds, and garnets.

- Durable: Constructed with wear-resistant, corrosion-resistant materials for extended longevity.

Forui Machinery Factory is a professional manufacturer of beneficiation equipment. Our factory has designed ruby and sapphire washing lines. It can conduct beneficiation tests and design processes for customers free of charge. If you need washing machine and process flow, Contact Us.