Product

Calcium carbide slag processing program is a feasible program summarized by Forui Machinery based on many years of practical experience, which can not only pretreat calcium carbide slag to meet the requirements of further recycling, it can also recover ferrosilicon from calcium carbide slag for profit. Calcium carbide slag can be recycled as a raw material for construction, but the ferrosilicon in it seriously affects the quality of the material, so in order to make scientific and effective use of calcium carbide slag, the first task is to recover the ferrosilicon.Forui Machinery has recovered ferrosilicon from calcium carbide slag with simple equipment such as trommel screen and jigger, which is not only small investment and low cost, but also considerable profit, and most importantly, paves the way for further recycling of calcium carbide slag. The following is the ferrosilicon we obtained from washing calcium carbide slag with jigger:

Features

The calcium carbide slag processing program has the following characteristics:

- The process used in the calcium carbide slag processing program is simple, reliable and practical, with a small investment in equipment, and can achieve the desired effect simply by using equipment such as trommel screens and jigging machines.

- It is a program designed by us based on years of practical experience, and the process and equipment have good practicality.

- The specific gravity difference between calcium carbide slag and ferrosilicon is very big, the effect of using jigger to sort is very ideal, and the plant adopts recycled water, without using any chemical, no secondary pollution.

Technological Process

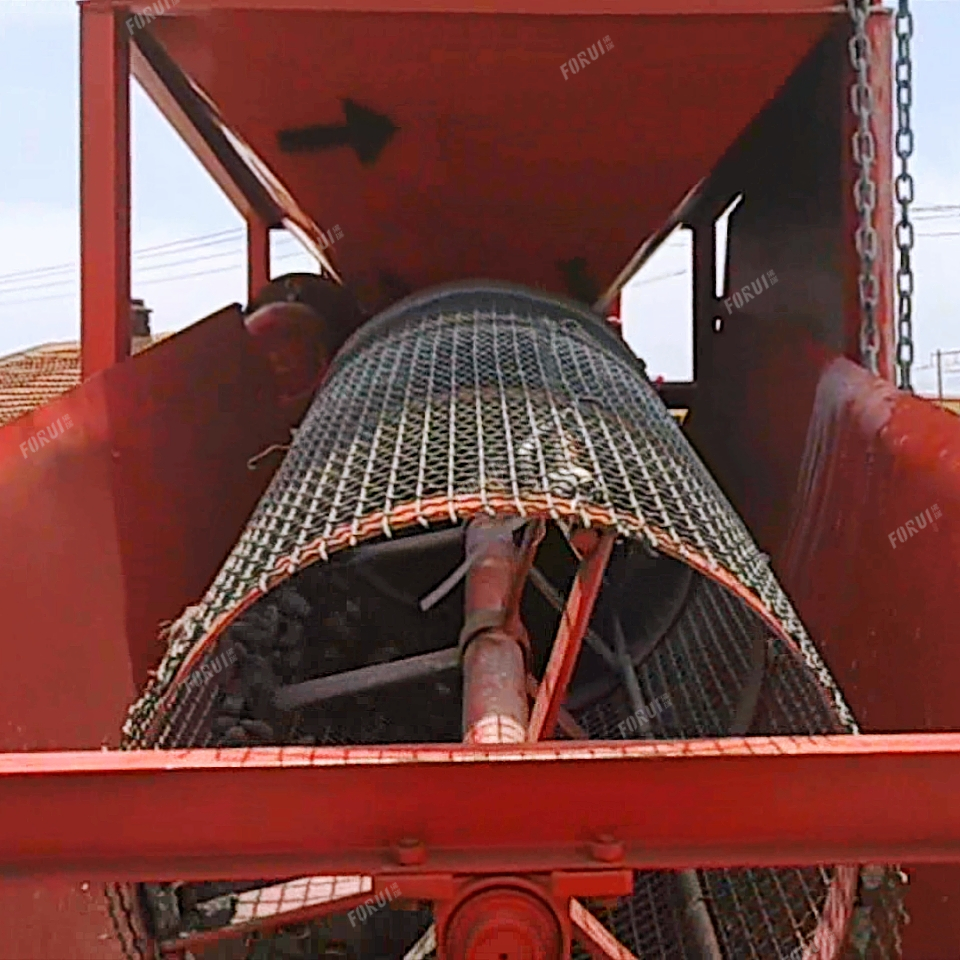

The calcium carbide slag processing solution adopts the process flow of screening, jigging and dewatering. The calcium carbide slag is evenly fed into the trommel screen for sieving, and sieved into three different particle grades of +30mm, 8~30mm and 0~8mm:

- +30mm: manually picked out large pieces of ferrosilicon

- 8~30mm: into the large particle jigger to recover coarse particles of ferrosilicon alloy

- 0~8mm: into the fine particle jigger to recover medium and fine particles of ferrosilicon alloy

The tailing slag produced by the jigger then enters the dewatering screen for dewatering and stockpiling. This completes the processing of the calcium carbide slag, while creating considerable economic benefits. We would like to remind you that not all calcium carbide slag contains ferrosilicon, and some calcium carbide slag does not contain ferrosilicon at all, which makes it unsuitable for this solution. Therefore, before using Forui Machinery’s calcium carbide slag processing program, be sure to determine whether the calcium carbide slag contains ferrosilicon.

Client Case

Carbide Slag Processing Plant in Mongolia, China

Carbide Slag Processing Plant in Changzhi, China

Online Consultant

Forui Machinery, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. If you have any questions, feel free to Contact Us.