Introduce

Chromite is a magmatic mineral, often produced in ultramafic rocks, where it is syngenetic with olivine and also commonly found in placer ores. It looks much like magnetite in appearance and is generally found in massive or granular aggregates. In the metallurgical industry, chromite is mainly used to produce ferrochrome alloys and chromium metal. Chromite is the only chrome ore with industrial mining value, and the commonly used beneficiation methods are gravity separation method and magnetic separation method. In actual production, chromite ore needs to make comprehensive use of gravity separation method and magnetic separation method to achieve the best beneficiation effect.

Technological Process

Chromite has a specific gravity of 4.3-4.8, and is generally present in the ore as a combination of lumps or grains, with a significant specific gravity difference from the vein, so gravity beneficiation is one of the most common methods of chromite beneficiation. Chromite has another special property, it has weak magnetic properties. This characteristic determines that the magnetic separation method is also an effective chromite ore beneficiation method. In actual production, we often have to determine whether to use gravity separation method, magnetic separation method or combined gravity separation-magnetic separation method according to the specific nature of chromite ore.

In general, for coarse-grained chromite, gravity separation can be used directly to obtain the desired results. For medium and fine grained chromite, gravity separation can produce part of the concentrate, but there are some congeners in the tailings, which must be further ground for further purification. Therefore, magnetic separation is required to sweep the tailings from the gravity separation method, and the obtained coarse concentrate is further ground to obtain the final fine-grained concentrate using a shaking table. This combined gravity separation-magnetic separation-gravity separation method can achieve the best beneficiation effect for chromite with medium and fine embedded grains.

Chromite ore beneficiation rarely uses a single magnetic separation method, the reason is that the magnetic separation method is easy to recover the congeners in the beneficiation process, and it is difficult to control the concentrate grade and recovery rate. Therefore, the magnetic separation method is only used as an auxiliary gravity beneficiation method, and is not used alone in chromite ore beneficiation.

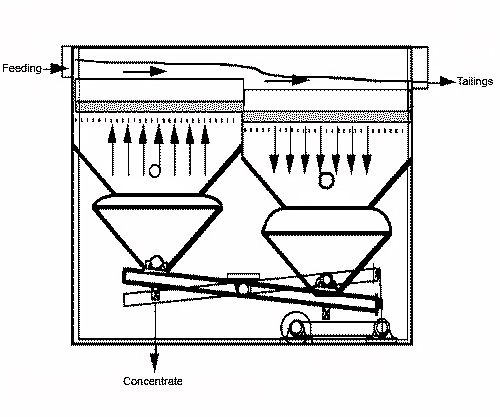

The beneficiation equipment of chromite ore mainly includes crusher, rod mill, jigger, magnetic separator, shaking table and so on. After the ore is crushed by two-stage crusher, it enters the rod mill for grinding, and the grinding product enters the jigger for purification. The concentrate produced by the jigger is the final concentrate, and the tailings enter the magnetic separator sweep, and the magnetic separator tailings are discarded. The concentrate from the magnetic separator enters the ball mill for further grinding, and the ground product enters the shaking table for further purification to obtain the final concentrate.

Client Case

Forui chromite ore processing jigger sent to Vietnam (16 sets of large downward moving LTA1515/2 jigger sent to Vietnam to process chromite ore):

Online Consultant

Gongyi Forui Machinery Factory, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. If you have any questions, feel free to Contact Us.