Product

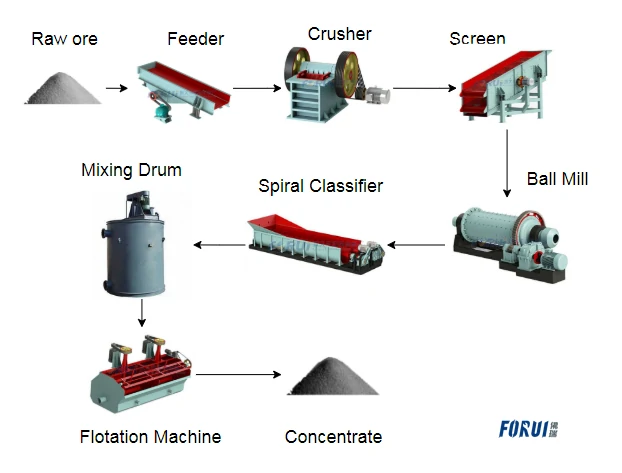

Copper ore gravity beneficiation production line is a production line used to upgrade the grade of low grade copper ore, it mainly consists of crusher, fine crusher, vibrating screen, jig machine, dewatering screen and other equipment. Due to the low copper content of low-grade copper ore, the direct use of flotation is too costly and does not have too high beneficiation value. Copper ore can reach the flotation feed grade after pre-selection by gravity separation production line, which not only can significantly reduce the cost of beneficiation, but also has an extremely important significance to reduce the investment of subsequent flotation equipment.

Technological Process

Copper ore can be divided into copper oxide ore and copper sulfide ore according to the different chemical properties, and its beneficiation methods include gravity separation pre-selection and flotation selection. With the increasing severity of ore mining, most of the copper mines in China have started to be depleted, and a large amount of low-grade copper ore cannot be effectively treated, resulting in the waste of useful resources. In order to solve this problem, Forui Machinery has taken the lead in developing a process of copper ore pre-selection, which can enrich the low-grade copper ore in advance, and then enter the flotation process for selection after reaching the flotation entry grade. This method greatly reduces the cost of beneficiation, reduces the investment cost of beneficiation equipment, and also makes full use of low-grade copper ore resources.

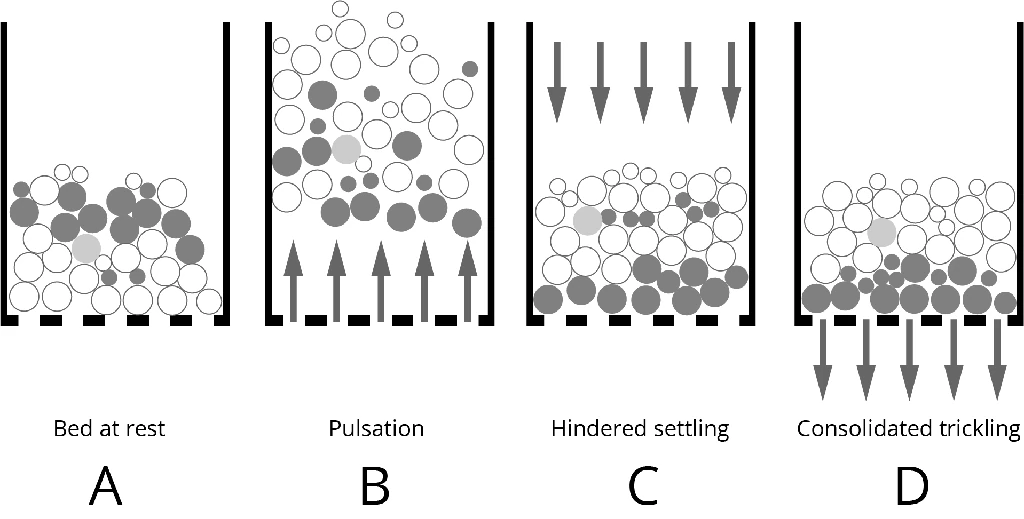

Copper ore gravity beneficiation is based on the density of copper minerals is greater than the density of the vein, the two have a very large specific gravity difference, in the theory of gravity beneficiation is easy to sort the minerals. We carry out gravity beneficiation by jig machine, the beneficiation effect is remarkable, and all the beneficiation indexes reach a satisfactory degree. Copper ore gravity separation line is mostly used for copper sulfide ore and coarse-grained embedded copper sulfide ore and copper oxide ore.

Client Case

Copper Ore Gravity Beneficiation Production Line in Philippines

Forui Machinery has supplied a copper ore gravity beneficiation production line with a capacity of 1500 tons per day to a customer in the Philippines, which consists of jaw crusher, spiral washer, high efficiency fine crusher, trapezoidal jigger, linear dewatering screen and other equipment. It enriches the Philippine copper sulfide ore by gravity beneficiation, and after enrichment, it enters into flotation process for further purification. The production line has the advantages of small equipment investment, large production capacity and low beneficiation cost. The beneficiation index has been highly recognized by the customer.

Yunnan copper-tin polymetallic ore gravity beneficiation production line

Yunnan Hualian Zinc Indium Co., Ltd. ordered a copper ore gravity beneficiation production line with a daily capacity of 2,000 tons from Forui Machinery to enrich its low-grade copper ore, and the enriched copper ore will then enter the flotation process for beneficiation and purification. The copper ore gravity beneficiation line mainly consists of jaw crusher, cone crusher, circular vibrating screen, vibrating feeder, trapezoidal jigger, linear dewatering screen and other equipment, and the beneficiation indexes are highly recognized by the customer.

Online Consultant

Forui Machinery, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. If you have any questions, feel free to Contact Us.