Product

Copper slag is the solid waste slag produced when smelting copper metal, these waste slags contain a certain amount of copper metal particles, depending on the smelting process, the copper metal content is also different. As the copper smelting process in some factories is relatively backward, so there are more copper metal particles in these copper smelting slags, and the recovery of copper metal particles from these smelting slags can generate very considerable economic benefits. So how can we recover copper metal particles from these waste copper smelting slag? Forui Machinery hereby introduces a copper slag processing line, which can effectively recover copper particles from copper smelting slag.

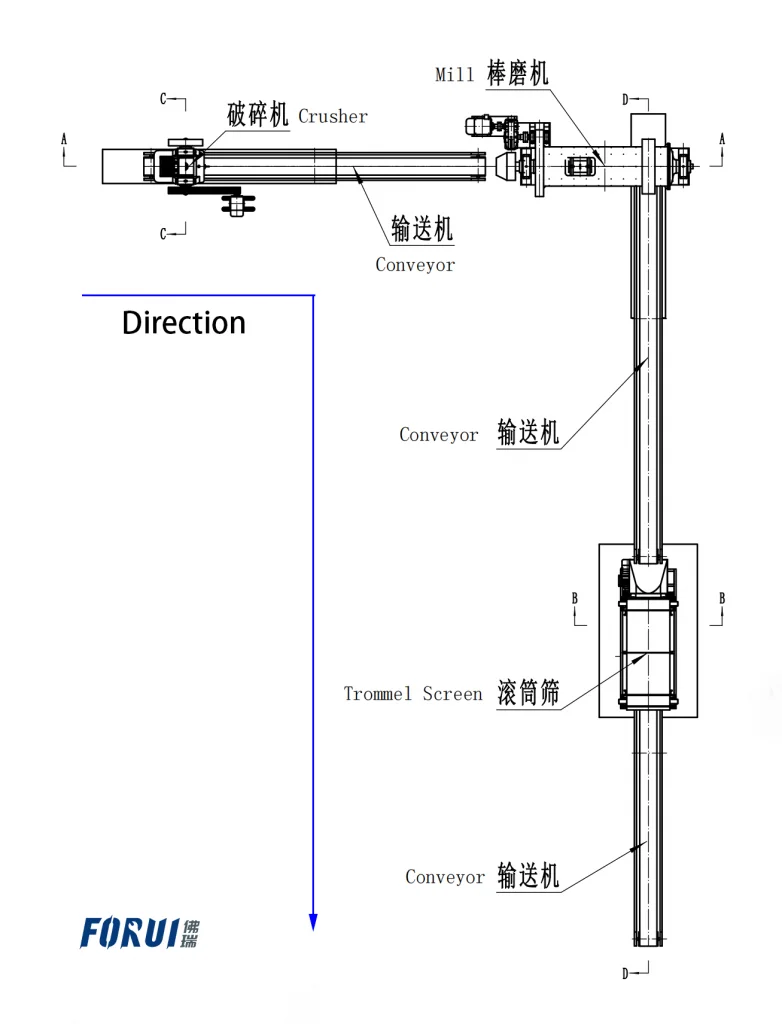

Technological Process

The most important function that copper slag processing production line should have is to recover copper metal particles from copper smelting slag. Therefore, the copper slag processing production line is similar to the mineral processing line, which should have the process of crushing, screening, washing and dewatering, and it can extract metallic copper from the slag.

The process flow of copper smelting slag to recover copper is roughly as follows: crushing – screening – jigging or shaking bed – dewatering. In general, copper slag in the metal copper particles are unevenly embedded in the copper smelting slag in the form of thick and thin beads, to recover these smelting slag in the metal copper, it is necessary to first let these slag and copper metal particles are separated, it is necessary to use crushing equipment, crushing can make the metal copper and slag monomer separation. After crushing, the particle size of the material is not uniform, some slag and copper metal have been separated monomerically, but there are still some not separated. Therefore, screening equipment is needed to process the crushed material, and the material that reaches the size range of the monomer dissociation will enter the next process, otherwise it will return to the crushing process to continue to crush. The configuration of the sorting equipment in the sorting process is very important, and there are usually two types, one is the most common jigger and the other is the shaker.

The jigger is mainly used to recover the coarse and fine uneven copper smelting slag, and the shaking bed is mainly used to recover the fine grained copper. After recovering the copper metal the slag usually also needs to be dewatered for stockpiling or transportation. Therefore, a reasonable dewatering process is mostly set up at the end of the copper slag processing line to meet the dewatering requirements for the concentrate and tailings. The commonly used dewatering equipment is linear dewatering screen.

Client Case

Online Consultant

Forui Machinery, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. If you have any questions, feel free to Contact Us.