Introduction

The diamond concentrator is diamond beneficiation equipment. The earliest beneficiation operation for diamonds was beneficiation with grease. It is one of the main selection methods for diamonds. The theoretical basis of the diamond concentrator is that in the separation system, diamond is oleophilic and hydrophobic (diamonds adhere to the grease), while other gangue minerals are hydrophilic and oleophobic (flow to the tailings bucket along the direction of the flushing water flow). Physical properties to achieve sorting.

Prior to this, the rough concentrate in the diamond concentrator was directly hand-selected. Not only the workload is quite large, but also difficult to guarantee quality. When the grease beneficiation method is adopted, the manual selection workload is reduced to 1/800 before, and the work efficiency is increased hundreds of times. Therefore, people in the industry have reason to believe that the grease separation method is the second milestone in the history of diamond beneficiation.

Working Principle

Grease beneficiation is a special beneficiation process that separates different minerals based on the lipophilic and hydrophobic characteristics of a diamond, using the selective collection effect of special grease.

The process of grease beneficiation is rough as follows: the prepared run of mine ore is applied to the separation surface coated with grease in the diamond concentrator, and flushing water is supplied at the same time. Due to the difference in lipophilic and hydrophobic properties of different mineral surfaces, lipophilic (hydrophobic) minerals adhere to the surface of the grease and become concentrates. The oleophobic (hydrophilic) gangue is not adhered to by the grease, and becomes tailings under the action of the washing water flow, thereby realizing the separation of different minerals.

For the diamond concentrate that has adhered to the grease, it needs to be deoiled and dried, while the grease is recycled, purified, and reused. The material for grease beneficiation is generally rough concentrate. The particle size is 1-5 mm, the largest can handle 20 mm lump ore, and the smallest can handle 0.5 mm ore powder.

Features

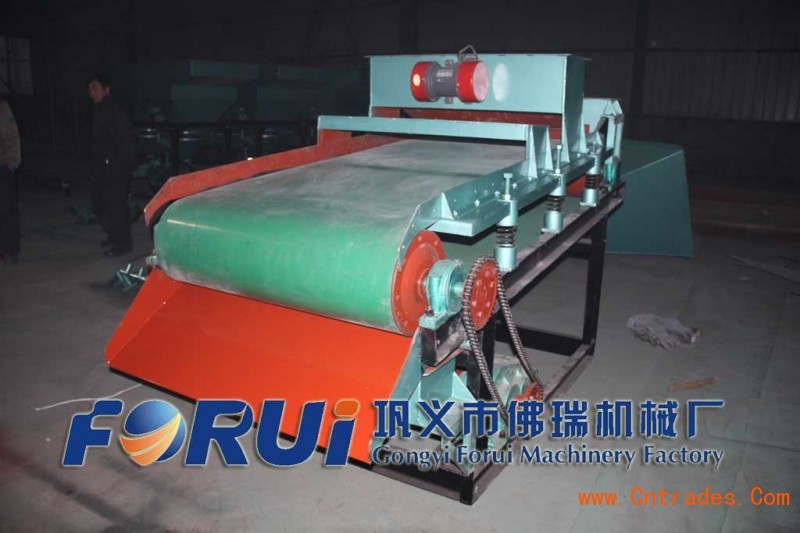

1.Vibration device (consisting of an eccentric wheel and 4 suspension spring rods) is installed under the sorting tape. This device makes the separation tape vibrate in the vertical direction, increases the number of times the mineral particles contact the surface of the grease, and is beneficial to the adhesion of diamonds.

2.The distance of the ore particles through the surface of the grease is relatively long, and there are more opportunities for sorting, which is beneficial to improve the recovery rate of the concentrate.

3.Large production capacity, three times larger than the non-vibrating belt type grease concentrator.

Online Consultant

Forui Machinery, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. Don’t hesitate to Contact Us, if you have any questions.