Introduction

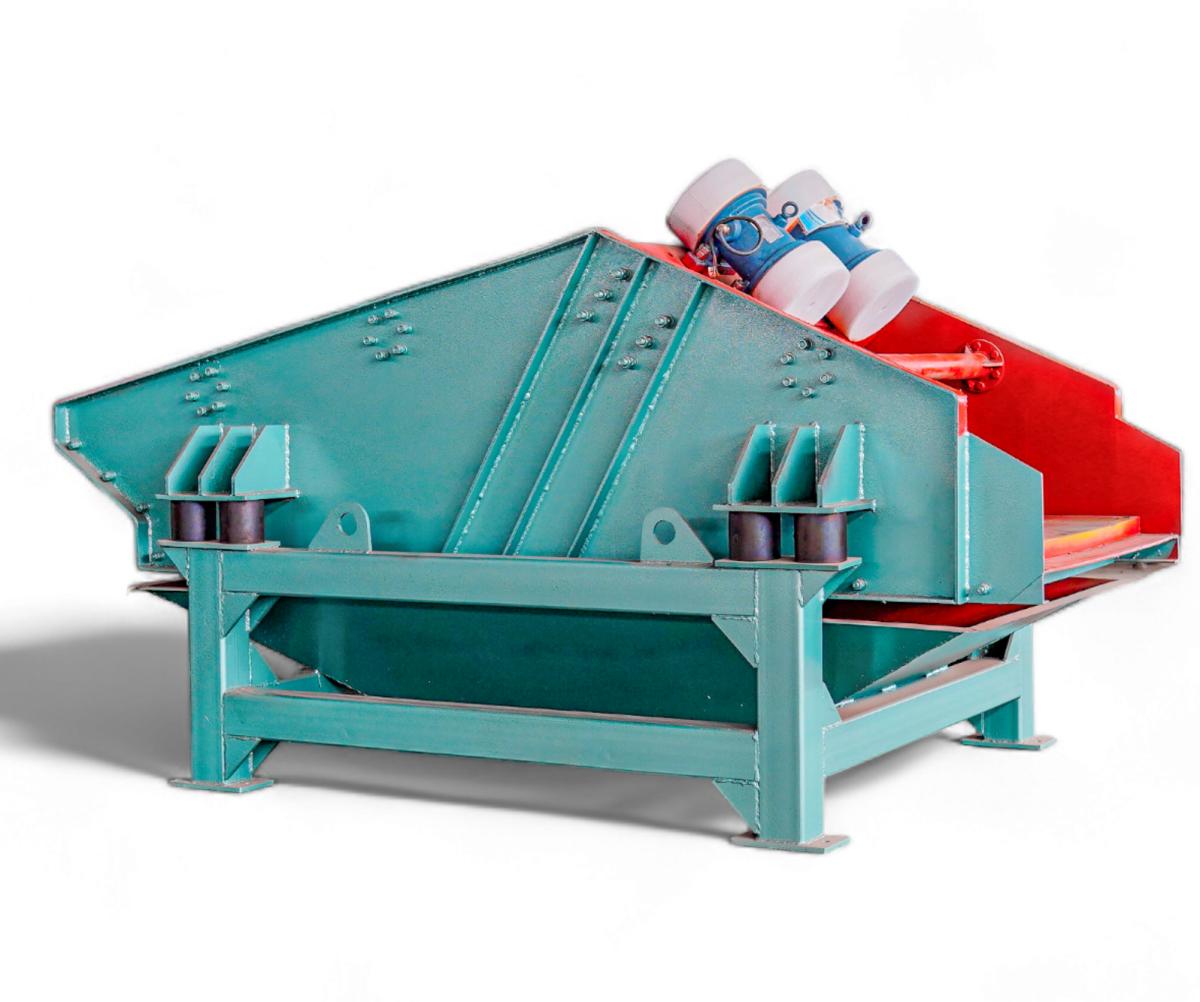

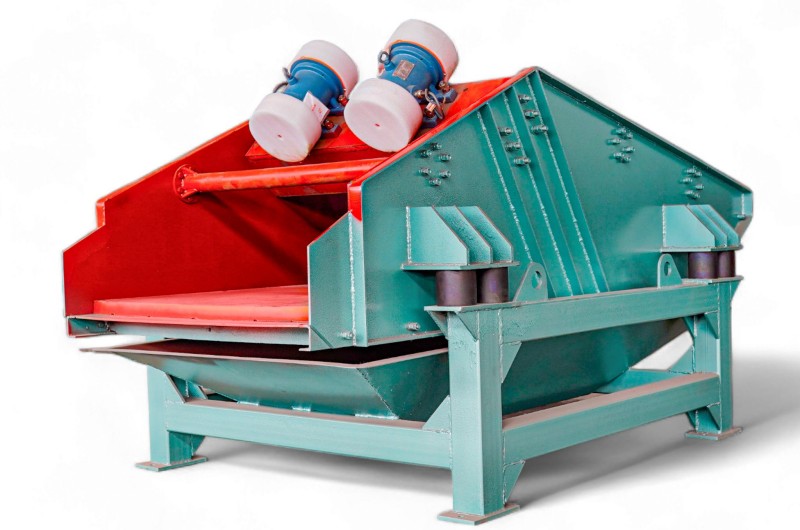

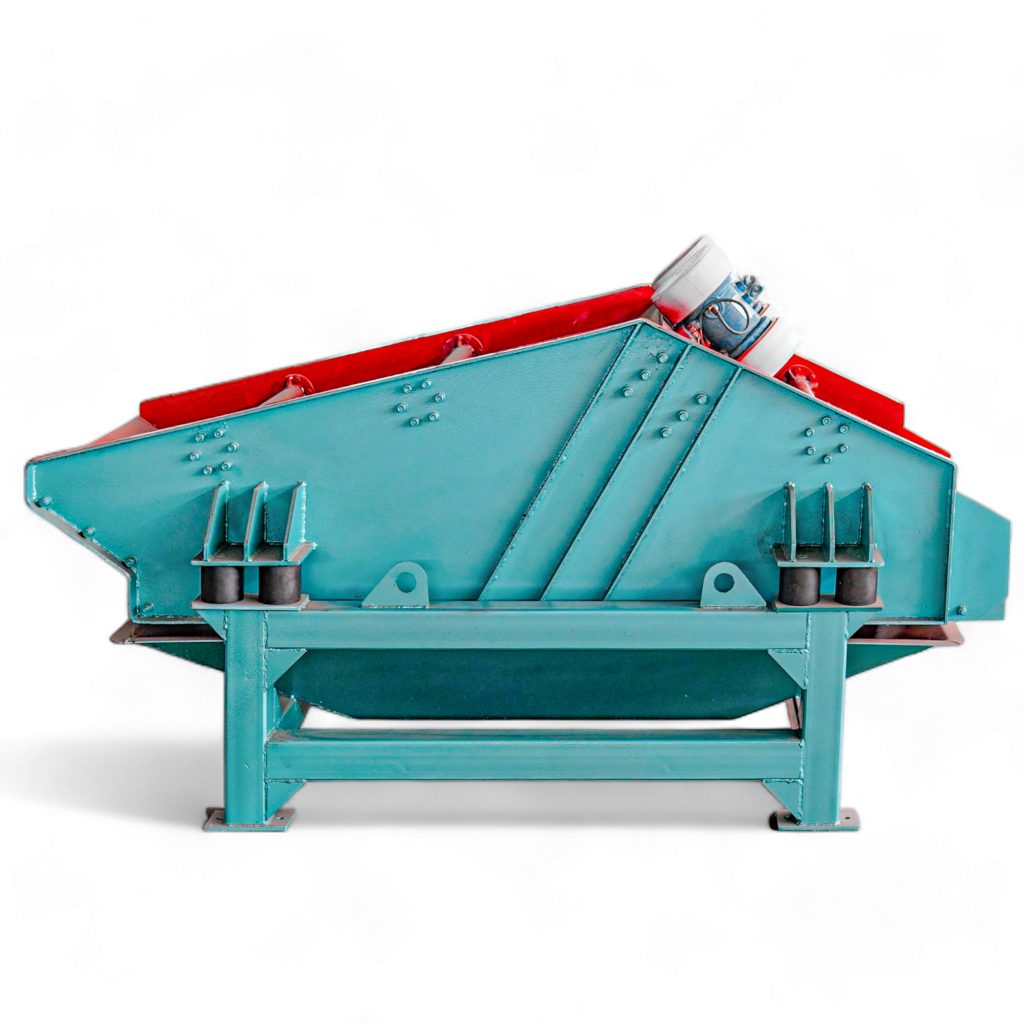

The TSS Dewatering Screen, also known as the High-Frequency Vibrating Screen, is a vibrating dewatering device designed for fine particle materials. By applying excitation force, it changes the surface tension of the slurry, allowing the water to pass through the screen and become the underflow, while the fine materials are blocked by the screen and form a filter layer that moves forward under the impact of vibration.

The TSS dewatering screen is mainly used for the dewatering of concentrates and tailings in the mineral processing industry, coal slurry dewatering in coal preparation plants, dewatering of washed quartz sand, ceramic slurry dewatering, as well as wet and dry classification and dewatering of medium and fine particles in the chemical industry, and dewatering of sludge in the environmental protection industry.

Features

1. Compact size with a large processing capacity per unit area, facilitating system layout.

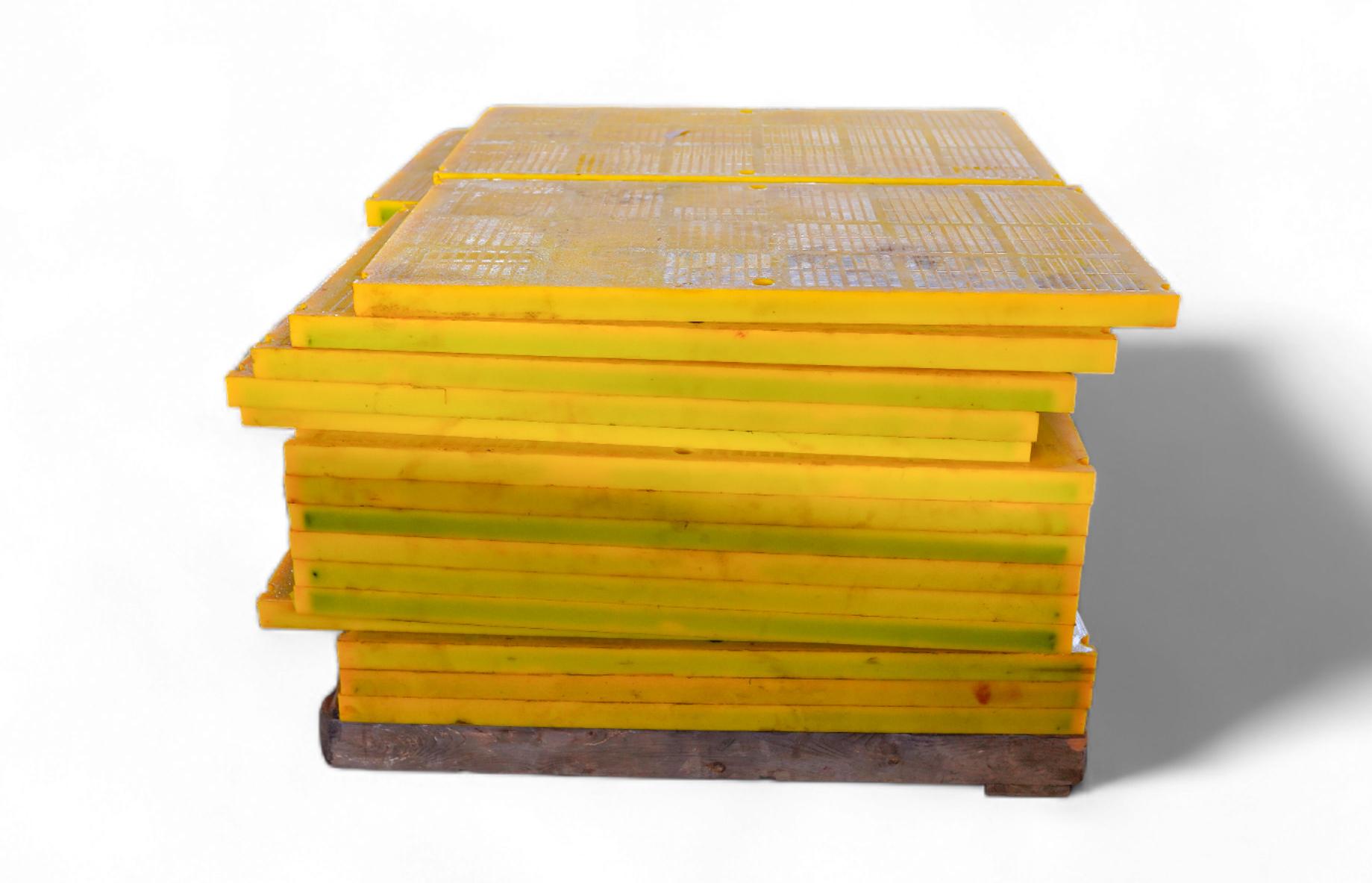

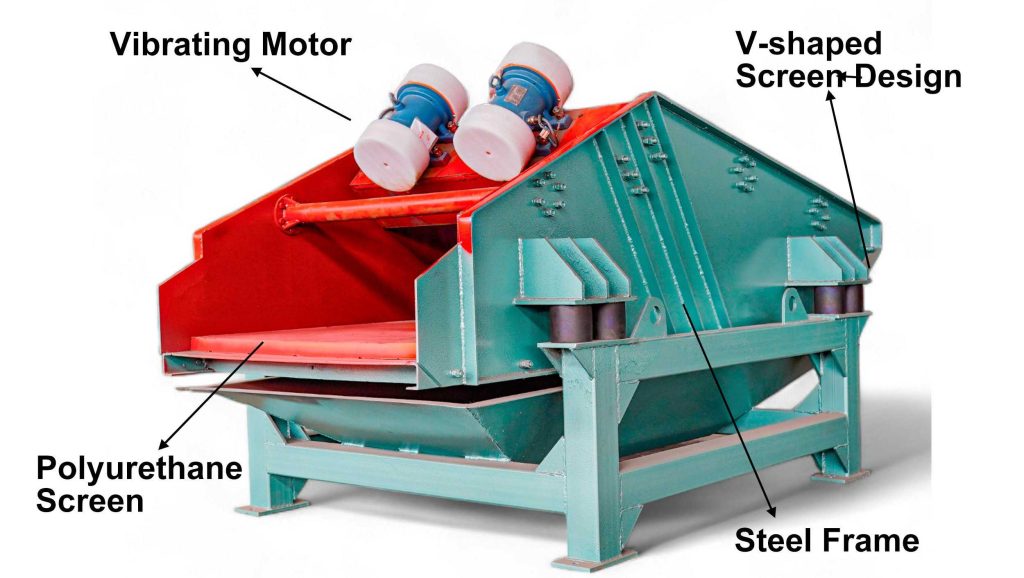

2. High wear-resistant polyurethane screen plates for long service life; modular design for easy replacement.

3. V-shaped screen surface design with a -5° slope for dewatering, allowing low moisture content in the discharged tailings and high dewatering efficiency.

4. High-frequency, low-amplitude, low-power consumption vibration source, suitable for various dewatering needs.

5. High strength and durability with steel frame components welded for enhanced stability.

Working Principle

The TSS dewatering screen utilizes two specially designed high-frequency, low-amplitude vibrating motors in reverse motion. The excitation forces in the same direction are combined, while those in the opposite direction cancel each other out, creating a single excitation force along the vibration direction. This drives the screen body to perform linear reciprocating motion, thereby removing excess water from the surface of the material.

Application

The TSS Dewatering Screen is suitable for dewatering and solid-liquid separation of a wide range of materials, including:

- Mineral Tailings: Dewatering of small size particlas, such as iron, gold, copper, vanadium, and graphite tailings.

- Sand and Minerals: Dewatering of quartz sand, zircon sand, and potassium feldspar.

- Wastewater Treatment: Dewatering of municipal wastewater, industrial wastewater, and river sludge.

- Sewage Treatment: Dewatering and solid-liquid separation in sewage treatment plants.

Its high-frequency, low-amplitude vibration ensures efficient dewatering and separation across these diverse materials.

Technical Parameter

| Model | Screen Size(L*W)(mm) | Layer | Mesh Size(mm) | Max Feeding Size(mm) | Capacity(t/h) | Power(Kw) |

| TSS 1530 | 3000*1500 | 1 | 0.2-6 | 8 | 15-40 | 1.5*2 |

| 2TSS 1530 | 3000*1500 | 2 | 0.2-6 | 8 | 15-40 | 1.5*2 |

| TSS 1540 | 4000*1500 | 1 | 0.2-8 | 8 | 25-60 | 2.2*2 |

| 2TSS 1540 | 4000*1500 | 2 | 0.2-8 | 8 | 25-60 | 2.2*2 |

| TSS 1548 | 4800*1500 | 1 | 0.2-8 | 8 | 30-70 | 2.2*2 |

| 2TSS 1548 | 4800*1500 | 2 | 0.2-8 | 8 | 30-70 | 2.2*2 |

| TSS1848 | 4800*1800 | 1 | 0.2-10 | 10 | 35-80 | 3.7*2 |

| 2TSS1848 | 4800*1800 | 2 | 0.2-10 | 10 | 35-80 | 3.7*2 |

| TSS1860 | 6000*1800 | 1 | 0.2-10 | 10 | 40-100 | 3.7*2 |

| 2TSS1860 | 6000*1800 | 2 | 0.2-10 | 10 | 40-101 | 3.7*2 |

Online Consultant

Forui Machinery, founded in 1986. We are one of the leading suppliers of beneficiation equipments in Asia. Don’t hesitate to Contact Us, if you have any question of beneficiation.