Product

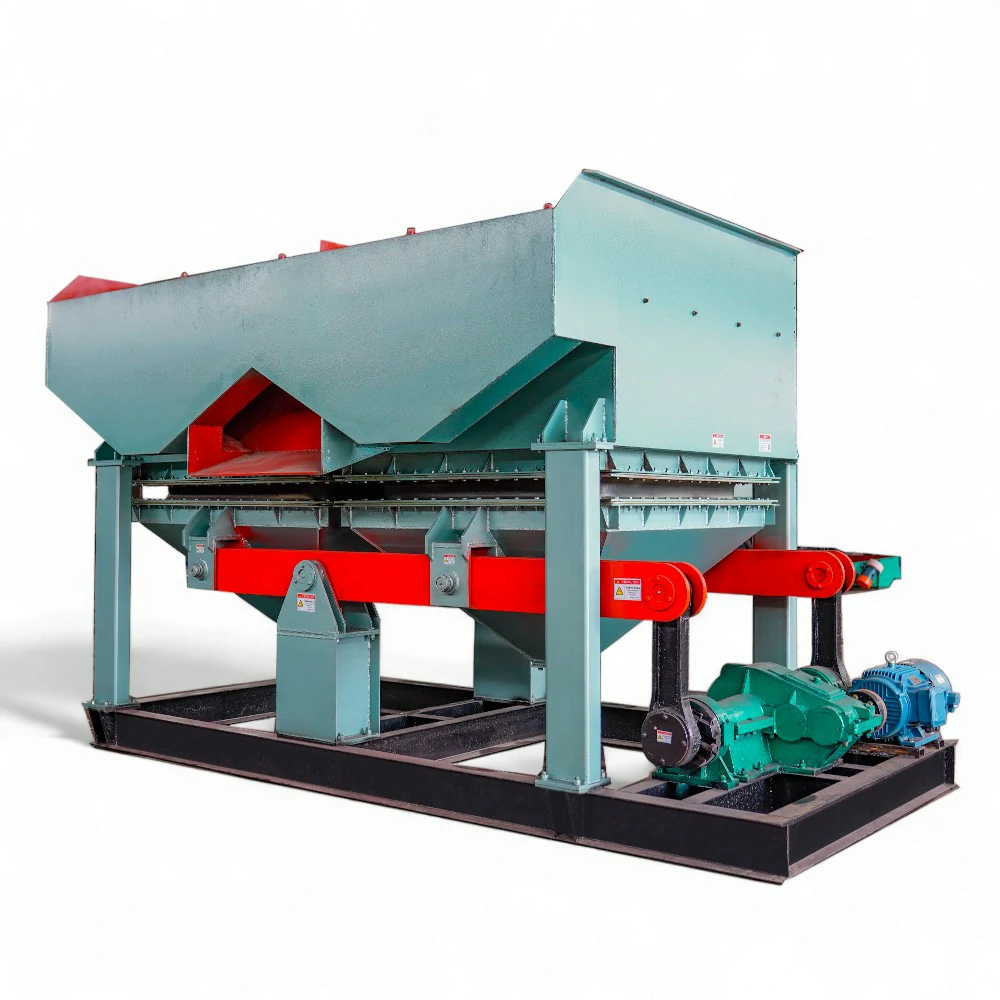

The FRT16-2 mineral jig concentrator from Forui Machinery stands out for its exceptional processing capabilities and large feed size, making it an ideal choice for medium and large-scale mineral processing operations. With an effective feed particle size of up to 50mm and a processing capacity of 60 tons per hour, the FRT16-2 jigging machine delivers exceptional productivity.

Designed to surpass the limitations of conventional jigging machines, the FRT16-2 boasts a significantly higher working strength, a broader stroke frequency range, and an enhanced stroke coefficient compared to its predecessors. These advancements translate into a range of benefits:

- Large Feeding Particle Size: Handle coarse mineral particles with ease, eliminating the need for pre-grading.

- High Output: Achieve impressive processing rates of up to 60 tons per hour, maximizing production efficiency.

- Simple Structure: Benefit from a straightforward design that minimizes maintenance requirements and enhances operational reliability.

- Small Footprint: Occupy minimal space, optimizing utilization of valuable processing facilities.

It has been proven that the FRT16-2 type jigging machine is highly effective in processing various minerals, including iron ore, manganese ore, barite, and other

Working Principle

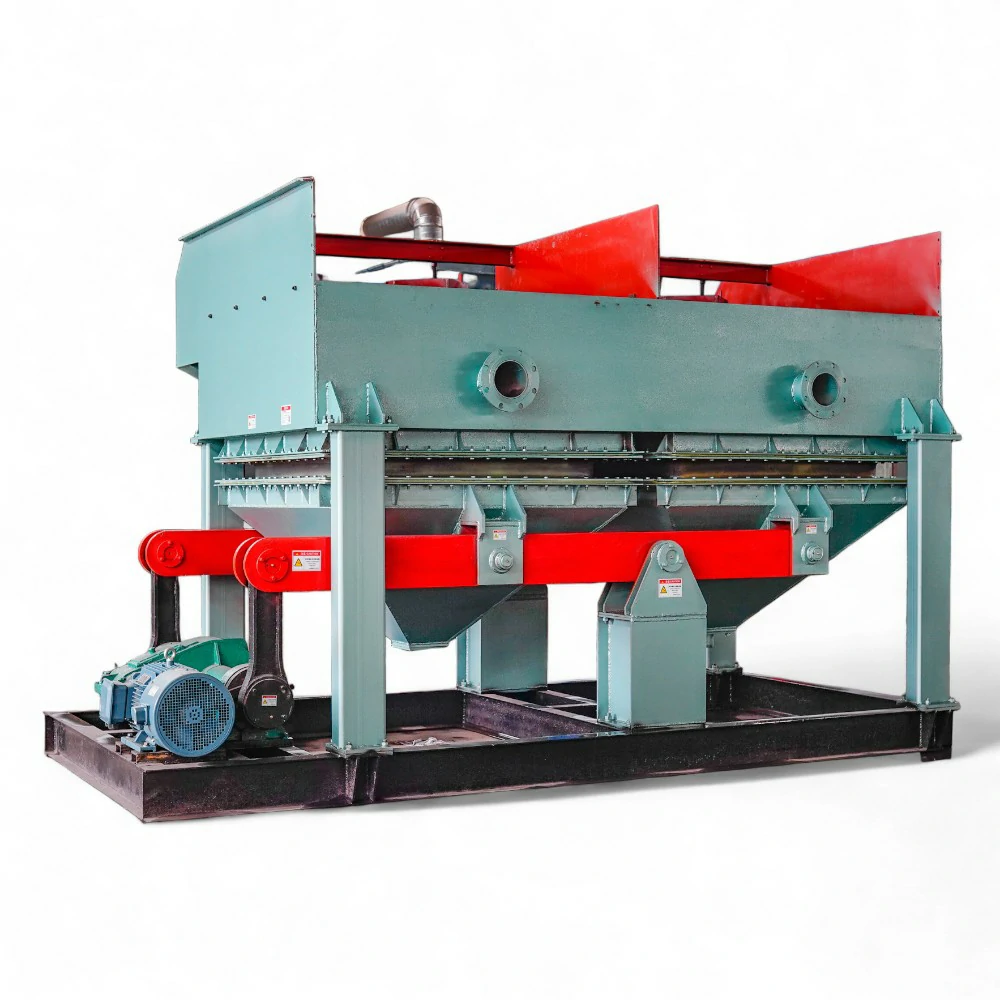

The 16-2 jigging machine is a mineral processing device that utilizes density differences to separate minerals. Its operation begins with the uniform feeding of crushed ore, at an appropriate particle size, into the machine’s feed chute.

The core component of the jigging machine is the lower-moving swing arm, which oscillates regularly up and down through an eccentric linkage mechanism. The amplitude and frequency of this motion can be controlled by adjusting the eccentricity of the eccentric shaft and the motor speed.

The swing arm’s motion drives the diaphragm and lower cone, generating a sinusoidal-like pulsating water flow within the jigging machine. This vertically alternating water flow force causes the minerals entering the separation compartment to stratify: denser minerals settle faster, occupying the lower layer, while less dense minerals settle more slowly, remaining in the upper layer. Due to this density difference, lighter materials struggle to penetrate the layer of heavier materials, thus achieving preliminary separation.

After separation, heavy minerals pass through the screen into the concentrate trough, while lighter minerals are conveyed to the tailings trough for discharge. Through continuous feeding, separation, and discharge, the 16-2 jigging machine achieves an efficient and continuous mineral processing operation. This density-based separation method enables the jigging machine to effectively process various types of ores, making it an essential piece of equipment in mining production.

Technical Parameters

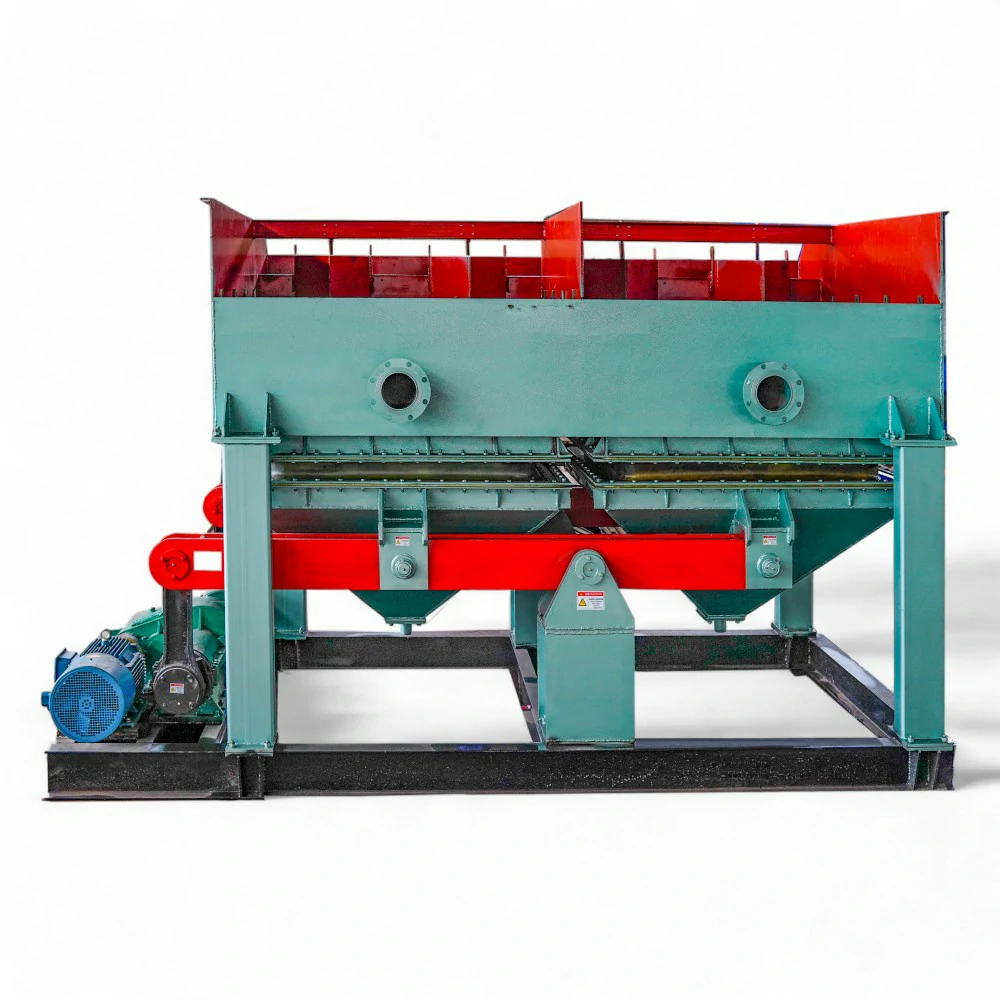

| Model | Feeding Size(mm) | Capacity(T/h) | Power(kW) | Jigging Area(m²) | Weight(t) | L*W*H(mm) |

|---|---|---|---|---|---|---|

| FRT16-2 | 0-50 | 40-60 | 18.5 | 5.12 | 7 | 4005*2609*2532 |

| FRT18-2 | 0-50 | 100~120 | 55 | 8.64 | 10 | 5170*3070*2390 |

| FRT18-2-A | 0-50 | 100~120 | 55 | 8.64 | 13 | 5170*3070*2390 |

Online Consultant

To find out more about our products and solutions, please fill out the form below and we will get back to you shortly.