Introduction

The GXD Automatic Centrifugal Concentrator

In the process of placer gold washing and separation, a gold centrifugal concentrator is mostly used as a mineral processing equipment, combined with skaing table, jig concentrator and other gravity separation equipment to complete the mineral processing and purification of coarse concentrate of placer gold ore. It is suitable for single gold recovery of placer gold, vein gold ore and polymetallic ore. It has the advantages of aotomatic, small area, easy operation, intermittent production and stable operation.

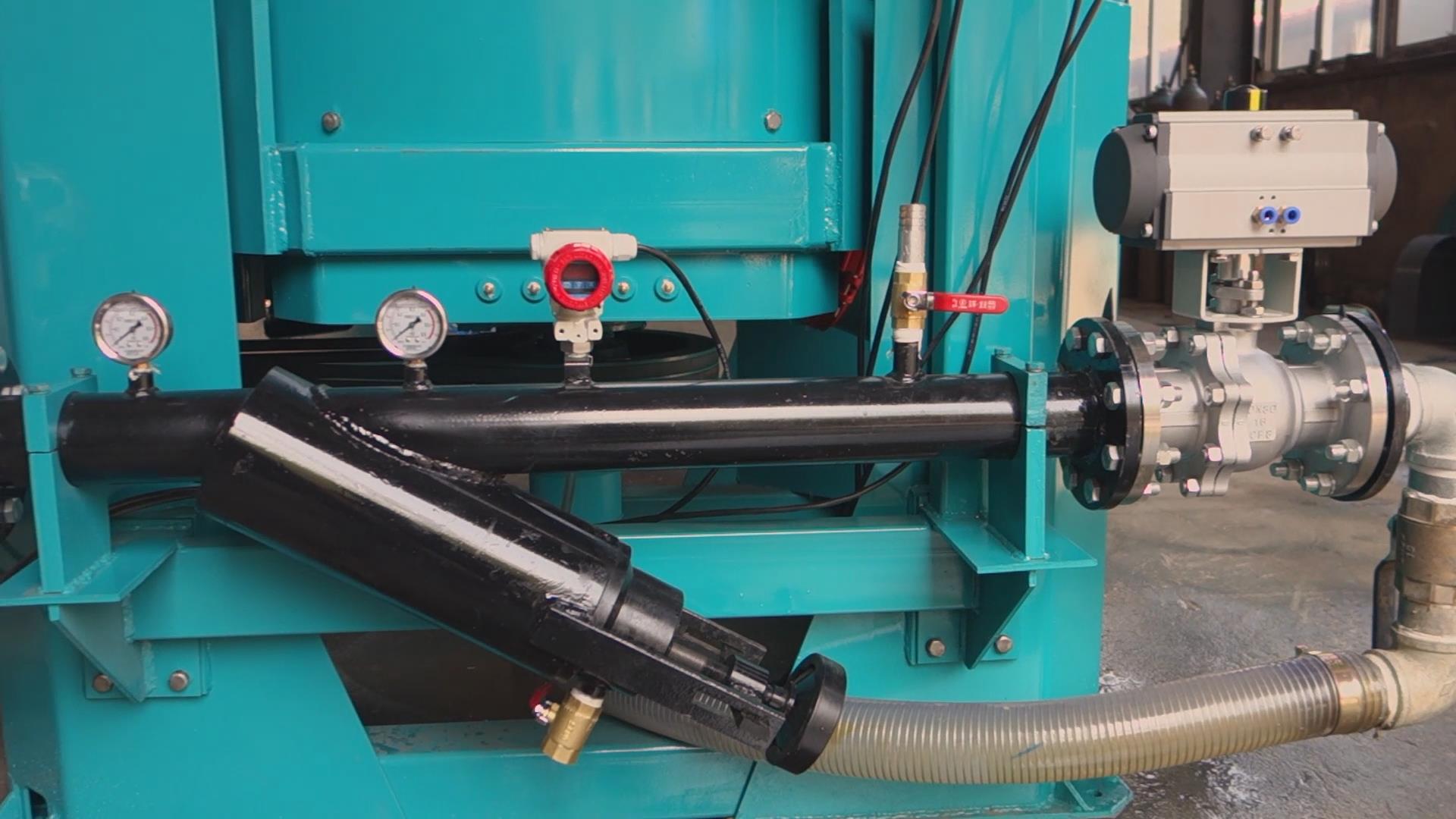

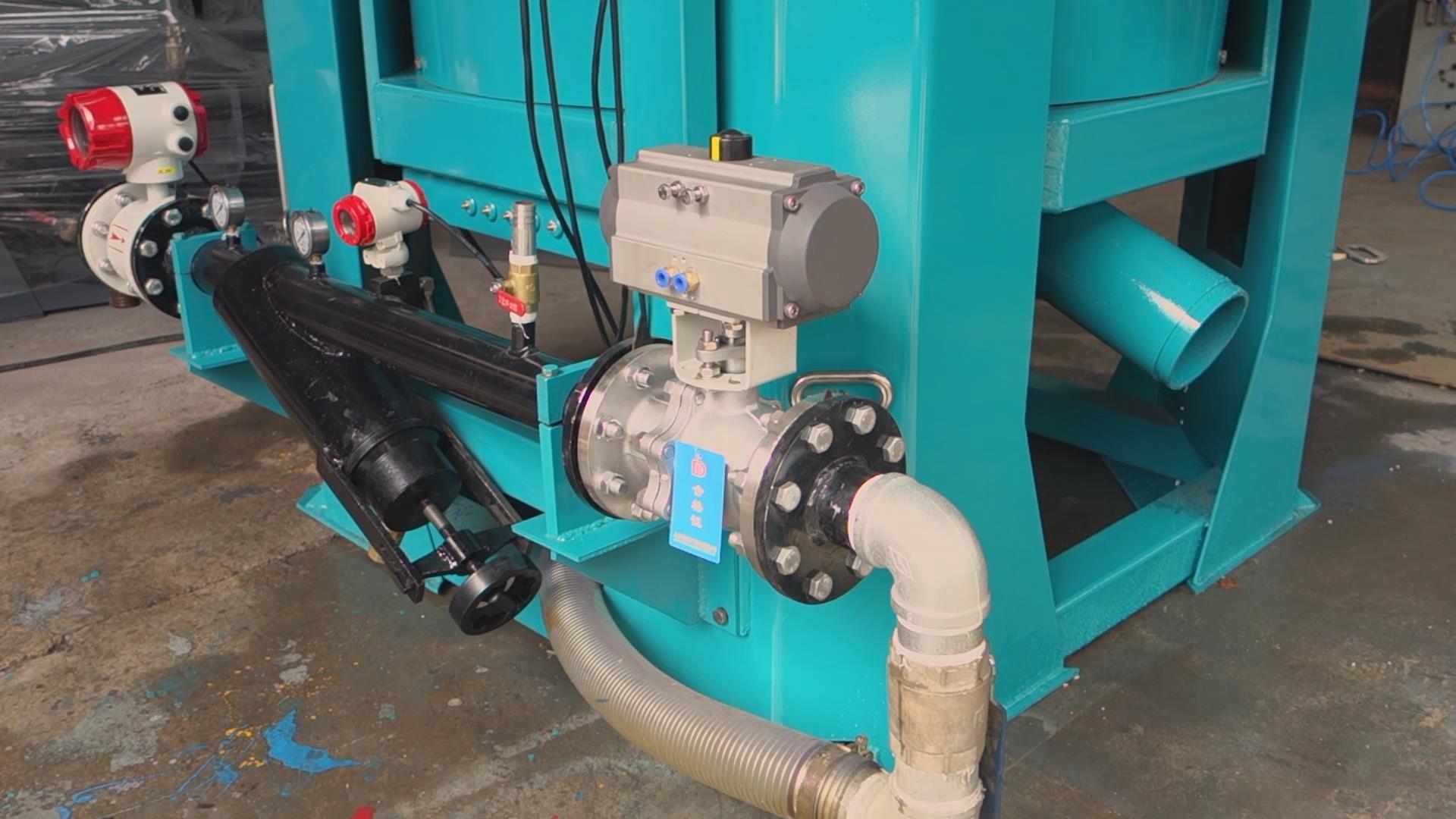

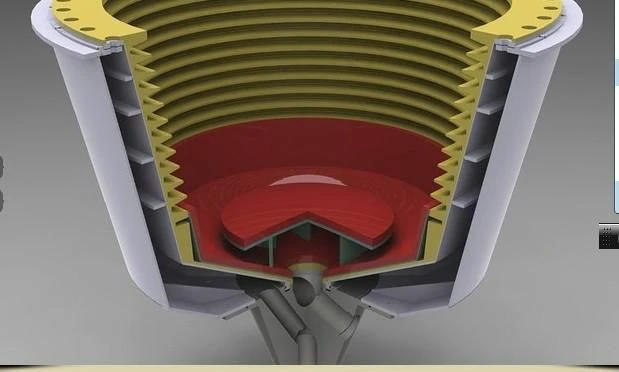

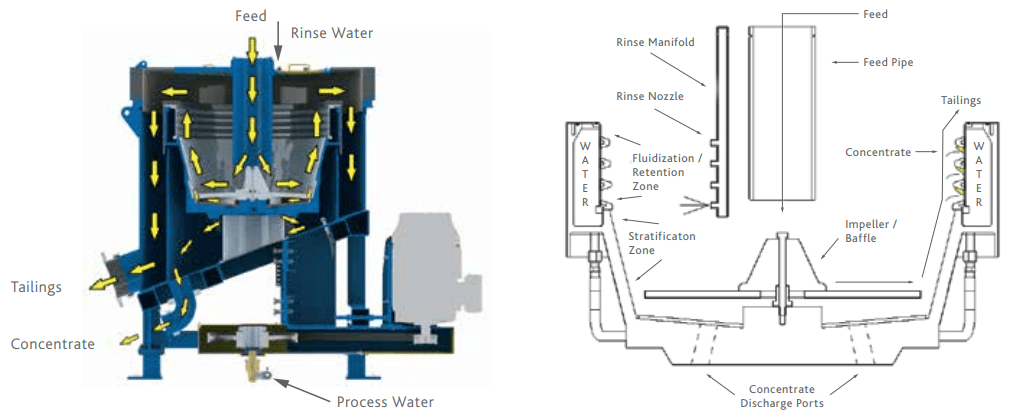

The GXD Automatic centrifugal concentrator is primarily composed of sorting cones, feed inlet, discharge outlet, water supply unit, driving device, and automatic control system, among other components. The core mechanism is the sorting cone, which consists of two vertically aligned, concentric cones that rotate together. Between the outer and inner cones, a sealed water cavity is formed. Inside the enrichment cone, there are several annular grooves with a diameter that gradually increases from the bottom to the top, and these grooves are distributed with fluidized water holes arranged according to a specific design.

The cone is driven by a motor, capable of generating an enhanced gravitational field of 60-120G. The ore slurry is fed into the top feed chute to gain kinetic energy and is then subjected to high-speed centrifugal motion by the cone.

The GXD energy-saving cone design can reduce the water consumption of the centrifuge by 40%. The addition of a PLC automation system and electronic monitoring equipment allows the centrifuge to operate completely automatically, making it simple to control.

Working Principle

The drum of centrifugal concentrator rotates at high speed with a certain number of revolutions, and the slurry is fed into the inner wall of the drum by the feeder through the nozzle. The slurry rotates at high speed with the drum. Under the action of centrifugal force, the heavy ore is deposited on the inner wall of the drum and rotates with the drum.

In the process of rotation, the light ore particles rotate with a certain spiral angle from the feed end to the discharge end. After minutes of separation, the ore feeder automatically turns away from the original normal position and stops feeding the ore into the drum.

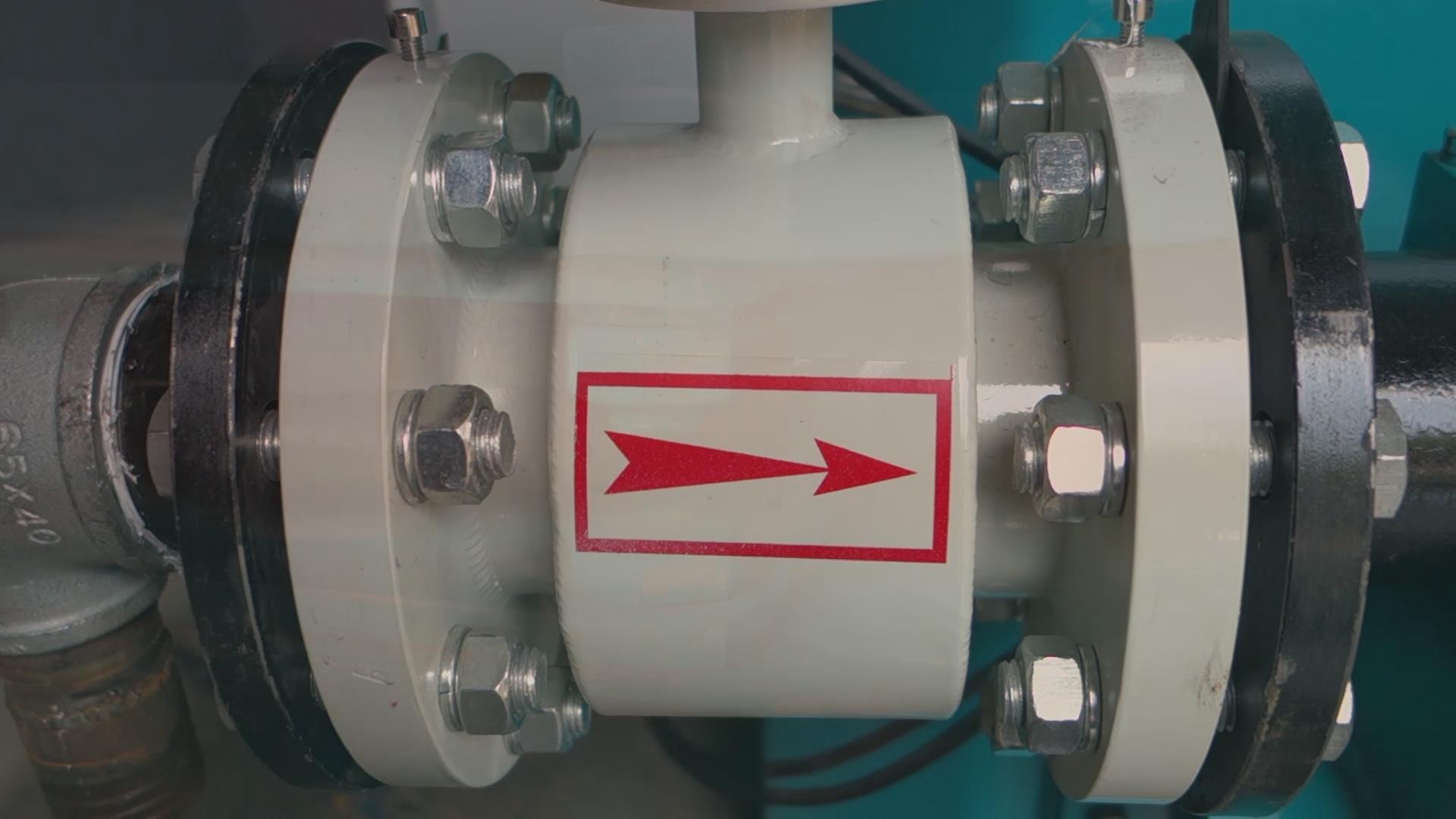

After the tailings are discharged, the ore separator automatically turns away from the original normal position to intercept the concentrate, then the high pressure flushing valve automatically opens, the high pressure flushing water punches the concentrate deposited on the inner wall of the drum, and the high pressure water valve automatically closes after the concentrate is washed.

Features

- High enrichment ratio (up to several thousand times).

- The recovery rate of fine grain gold can reach more than 95%.

- Automatic discharge of concentrate.

- The equipment occupies a small area.

- Stable operation.

Technical Parameters

| Model | GXD50 | GXD80 | GXD100 | GXD120 |

| Capacity | 15-50 T/H | 35-70 T/H | 60-120 T/H | 100-180 T/H |

| Max.feeding particle size | 6 mm | 6 mm | 6 mm | 6 mm |

| Recommended feeding particle size | -2 mm | -2 mm | -2 mm | -2 mm |

| Motor power | 5.5 KW | 11 KW | 22 KW | 30 KW |

| Water consumption | 10-15 m3/t | 16-25 m3/t | 25-45 m3/t | 40-65 m3/t |

| Single row of concentrate weight | 8-15 kg | 20-30 kg | 25-60 kg | 45-70 kg |

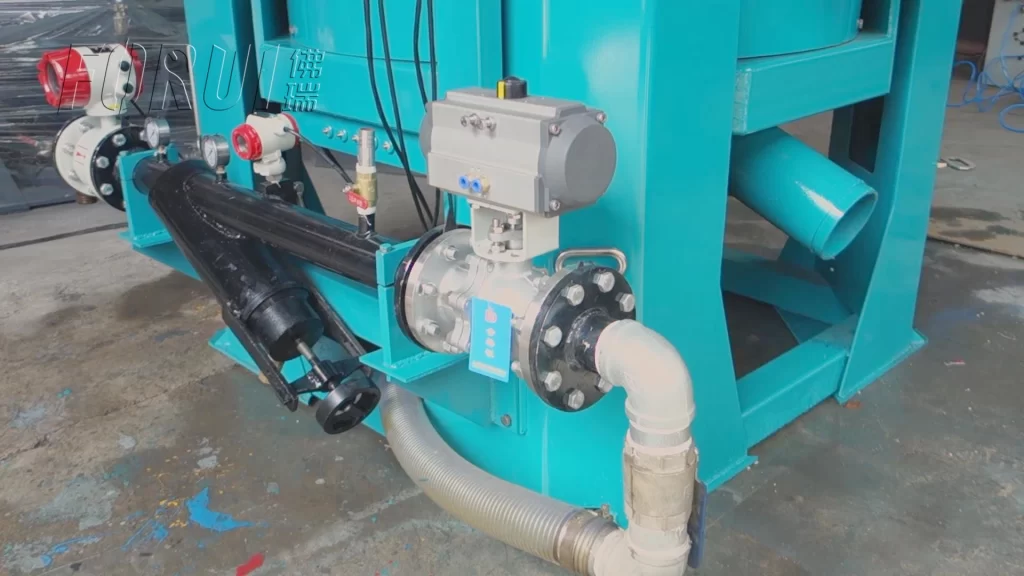

Product

Forui Machinery is founded in 1986. We are one of the leading suppliers of beneficiation equipments in Asia. Don’t hesitate to Contact Us, if you have any question of beneficiation.