Introduction

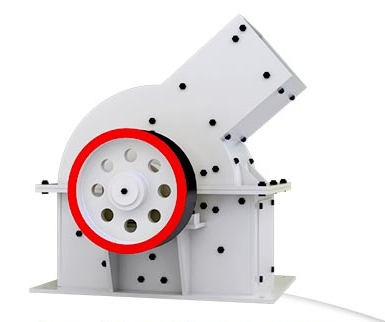

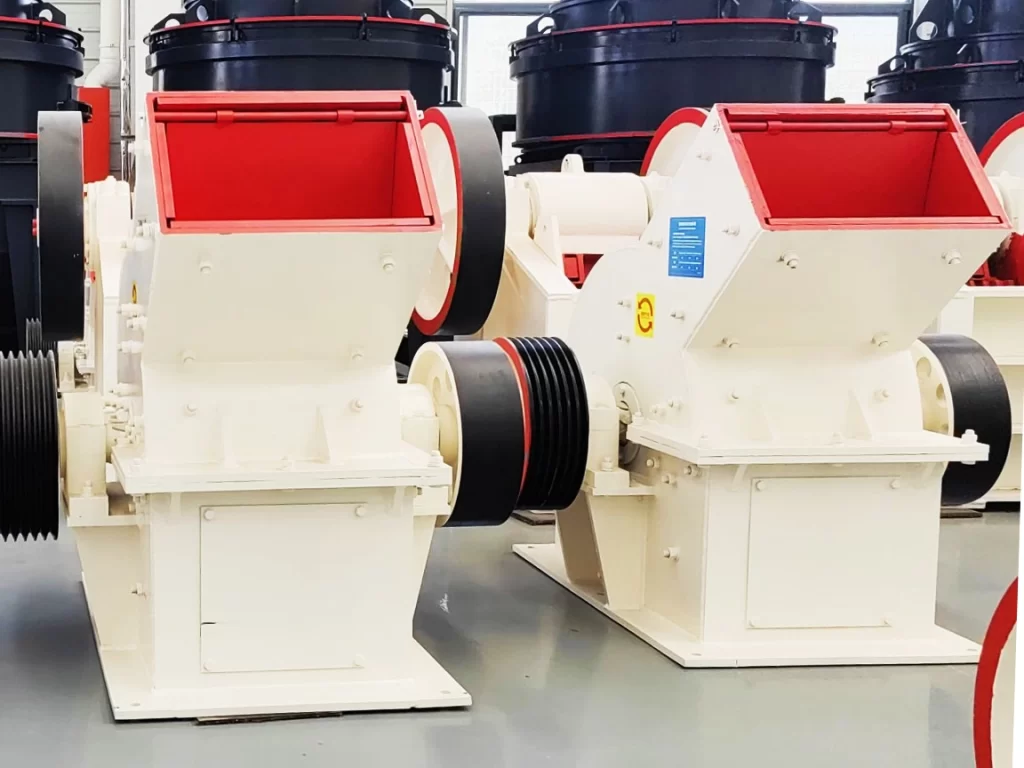

Hammer crushers are primarily used for breaking materials with a compression strength that is less than 200MPa, such as limestone, gypsum, coal, marlstone, sandy shale, etc.

The processing capacity of conventional hammer crusher can reach 200 T/H, and the capacity of heavy hammer crusher can reach 1200T/H.

The hammer crusher can not only be used in stone crushing lines in aggregate plants, but also in the ore processing line instead of cone crushers.

Hammer crushers generally have a crushing ratio of 10 to 25, which can crush the raw ore into small particles of 2mm in a single process. The grizzly bars and screen of hammer crusher can be adjusted to meet different particle size as requirements.

Working Principle

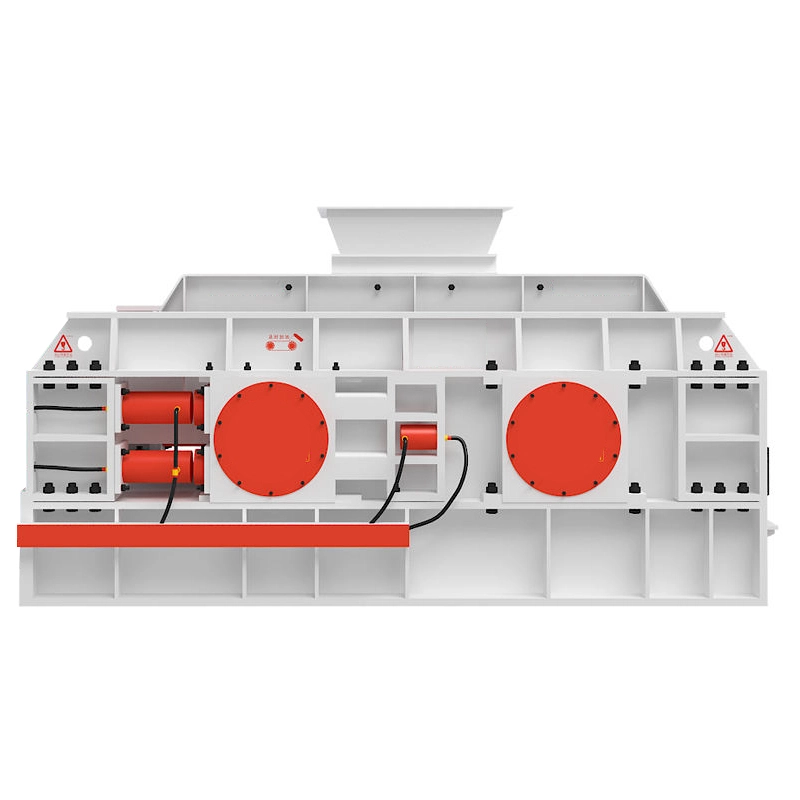

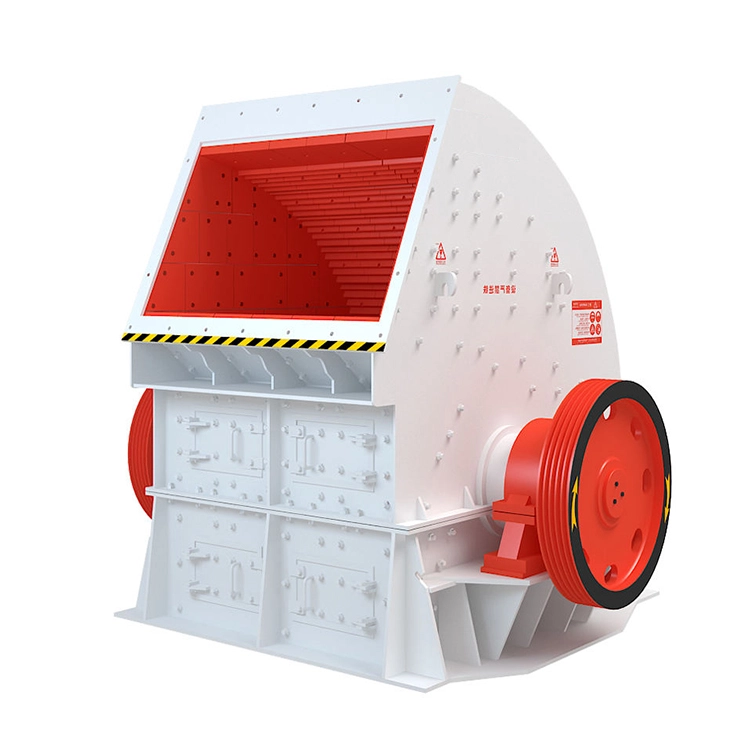

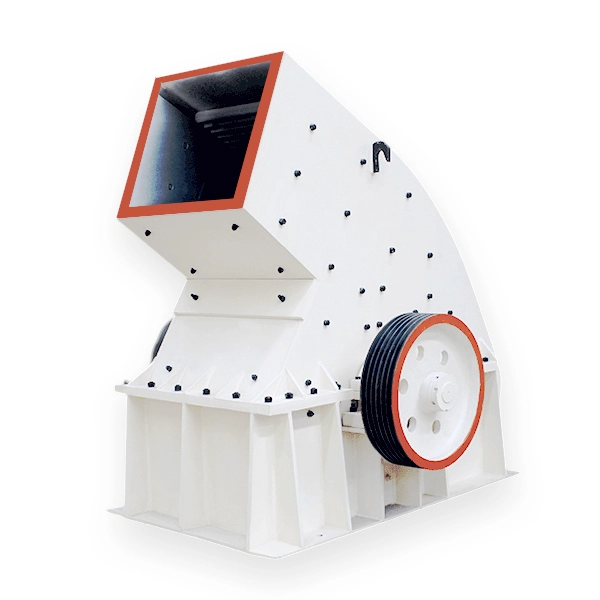

The main working part of the hammer crusher is a rotor with a hammer (also known as a hammer head). The rotor consists of the main shaft, a disc, a pin, and a hammer. The motor drives the rotor to rotate at high speed in the crushing cavity. The material is fed into the machine from the upper feeding port, and is crushed by the impact, impact, shearing, and grinding action of the high-speed moving hammer. In the lower part of the rotor, there is a sieve plate, and the particles smaller than the sieve hole size in the crushed material are discharged through the sieve plate, and the coarse particles larger than the sieve hole size remain on the sieve plate and continue to be hit and ground by the hammer, and finally pass through the sieve plate Exhaust from the machine.

Features

- The hammers are made of new wear-resistant alloy material and casted by new technology which has good wear resistance and impact resistance.

- The rotor of this hammer crusher features a great inertia and high rotating speed, and the linear velocity of the hammer reaches 30~35m/s.

- The product size can be adjusted by variety of the grizzly bars and screens in order to meet different product demands.

- Due to its large feeding size design, a variety of minerals can be fed into hammer crusher.

- The mechanical structure of the hammer crusher is simple, it is easy to replace the hammers.

Technical Parameters

| Model | Max Feed Size (mm) | Discharge Size(mm) | Capacity(t/h) | Power(kw) | Weight(t) |

|---|---|---|---|---|---|

| Φ400×300 | 100 | 0-30 | 5-8 | 11 | 0.5) |

| Φ600×400 | 100 | 0-35 | 10-12 | 18.5 | 1.03 |

| Φ600×600 | 100 | 0-35 | 12-18 | 45 | 2.14 |

| Φ800×600 | 120 | 0-45 | 20-25 | 55 | 2.45 |

| Φ800×800 | 120 | 0-45 | 35-45 | 55 | 3.05 |

| Φ1000×800 | 200 | 0-45 | 25-40 | 110 | 6.5 |

| Φ1000×1000 | 200 | 0-45 | 40-80 | 132 | 7.6 |

| Φ1250×800 | 200 | 0-45 | 20-50 | 132 | 11.7 |

| Φ1250×125 | 200 | 0-45 | 90-110 | 185 | 13.2 |

| Φ1400×140 | 250 | 0-45 | 120-170 | 280 | 17.2 |

| Φ1600×160 | 350 | 0-60 | 220-280 | 450 | 22.8 |

Other Crushers

Online Consultant

Forui Machinery, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. Don’t hesitate to Contact Us, if you have any questions.