Introduction

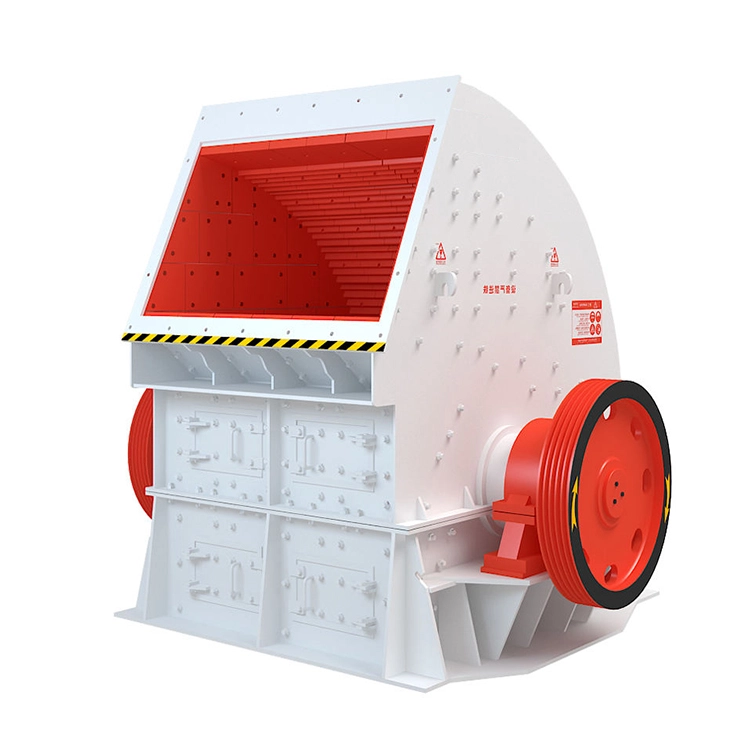

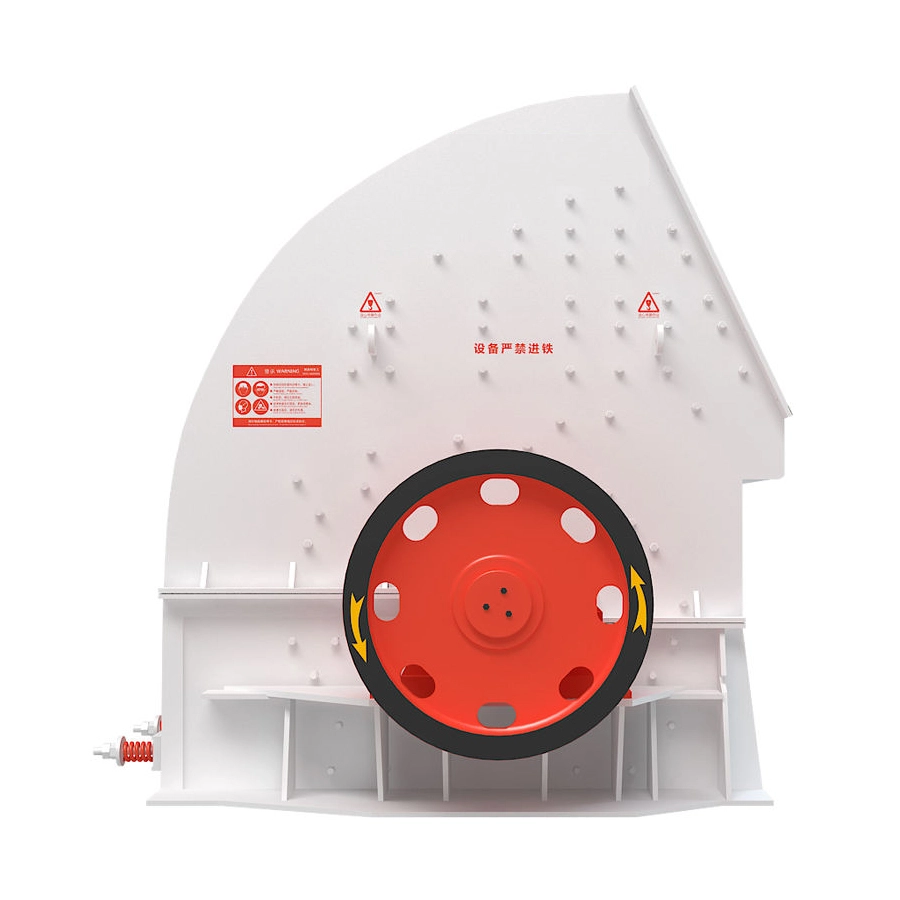

Heavy-duty hammer crusher, also known as a heavy hammer crusher, is ideal for crushing a wide range of medium-hard and brittle materials. It boasts a high crushing ratio, exceptional production efficiency, and a comprehensive range of models. Capable of crushing materials to the final size in a single pass, eliminating the need for secondary crushing.

PCZ heavy-duty hammer crusher combines the advantages of the jaw crusher, hammer crusher, and impact crusher. It has a larger input size (≤1200 mm) and greater capacity (≤1200 t/h).

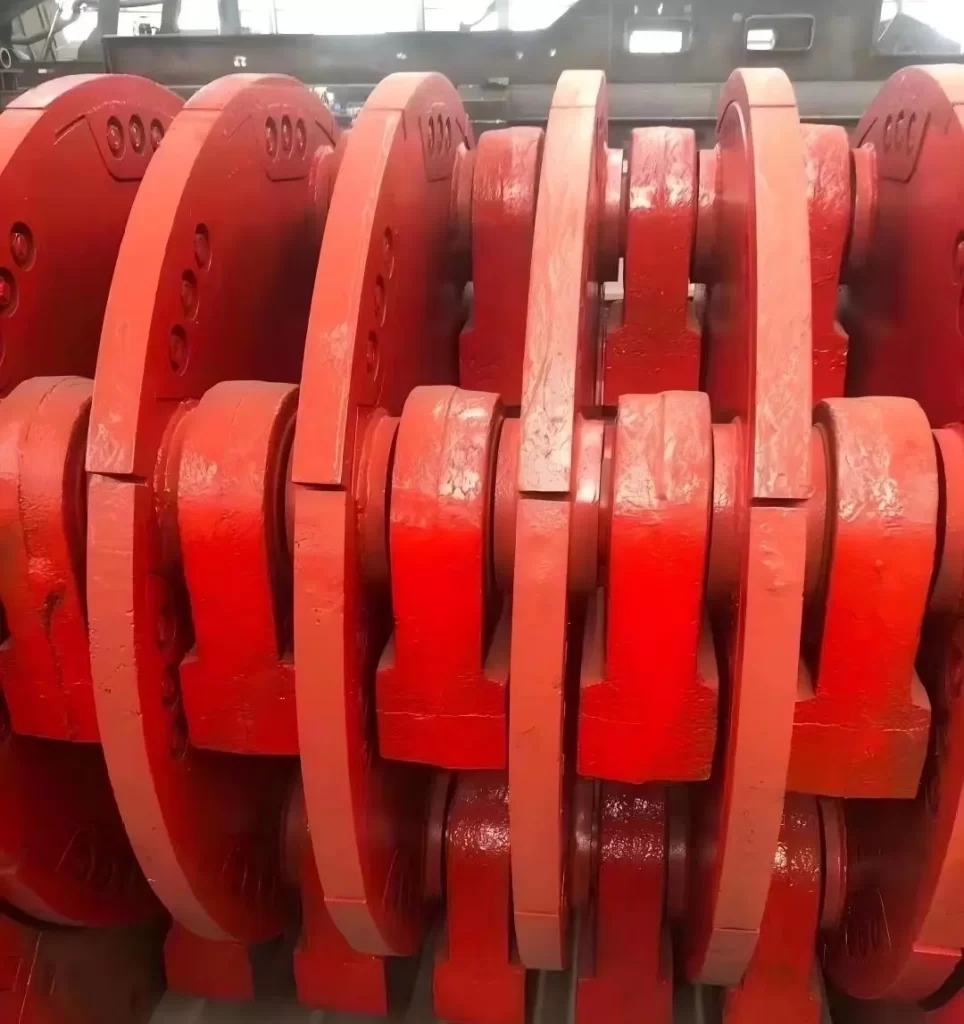

Compared to standard hammer crushers, heavy-duty hammer crushers feature heavier hammers and a more robust structure. They are primarily designed for coarse and medium crushing of larger materials, while standard hammer crushers are better suited for medium and fine crushing of smaller particles. Moreover, heavy-duty hammer crushers offer higher production capacities and produce coarser output, demanding more wear-resistant components to handle harder materials.

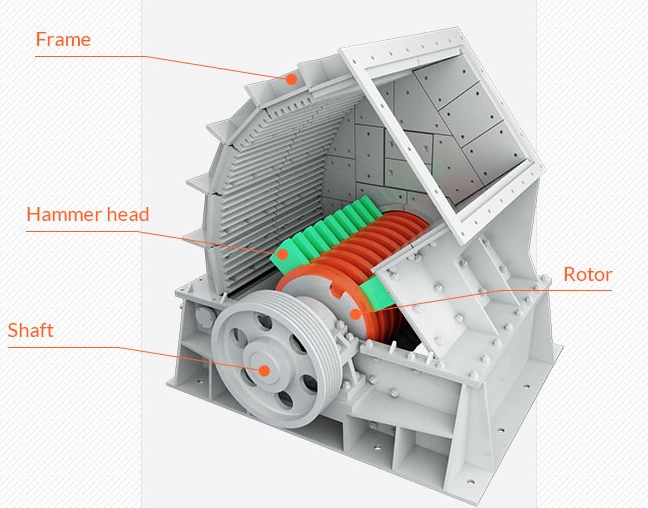

Working Principle

The heavy-duty hammer crusher mainly relies on impact energy to complete the crushing operation of materials. When the hammer crusher is working, the motor drives the rotor to rotate at a high speed, and the material enters the crusher chamber evenly. The high-speed rotating hammer head rushes towards the baffle plate and the sieve bar in the frame, and the material larger than the sieve hole size is retained on the sieve plate and continues to be hit and ground by the hammer until it is crushed to the required discharge particle size.

Features

- Large feed size: The feed particle size can reach 1600mm, the crushing ratio is high, and the output can reach 3000 tons per hour.

- Low cost: With powerful crushing force and the ability to achieve one-step shaping, this equipment eliminates the need for secondary crushing and shaping processes, reducing crushers procurement costs

- Alloy composite hammer: The Low alloy steel hammer head has longer service life Less wear and tear. Wear-resistant hammer head can reduce downtime and ensure production efficiency.

Technical Parameters

| Model | Rotor Dia(mm) | Inlet Size W*L(mm) | Max Feeding Size(mm) | Capacity(t/h) | Power(kw) |

|---|---|---|---|---|---|

| PCZ 0706 | 700*570 | 615*510 | 400 | 50-70 | 75 |

| PCZ 0808 | 800*750 | 780*610 | 500 | 80-100 | 132 |

| PCZ 0910 | 900*1000 | 1070*750 | 600 | 150-200 | 110*2 |

| PCZ 1012 | 1000*1180 | 1255*810 | 650 | 250-300 | 132*2 |

| PCZ 1213 | 1200*1280 | 1350*920 | 750 | 300-350 | 160*2 |

| PCZ 1216 | 1200*1590 | 1530*920 | 750 | 400-500 | 200*2 |

| PCZ 1220 | 1220*1950 | 2000*920 | 750 | 500-600 | 220*2 |

| PCZ 1310 | 1310*1050 | 890*1075 | 650 | 150-180 | 160 |

| PCZ 1512 | 1500*1160 | 1200*900 | 750 | 250-310 | 160*2 |

| PCZ 1513 | 1500*1350 | 1290*900 | 750 | 430-350 | 180*2 |

| PCZ 1615 | 1650*1452 | 1500*1200 | 1000 | 410-500 | 220*2 |

| PCZ 1620 | 1660*1900 | 2000*1200 | 1200 | 800-1200 | 400*2 |

| PCZ 1622 | 1620*2200 | 2200*1000 | 900 | 600-800 | 250*2 |

| PCZ 1815 | 1850*1520 | 1500*1280 | 1100 | 520-620 | 250*2 |

| PCZ 1820 | 1800*1964 | 2000*1200 | 1200 | 1000-1200 | 450*2 |

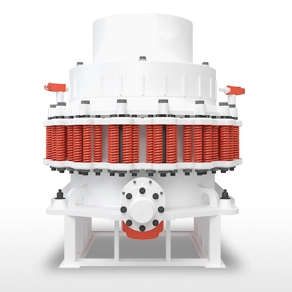

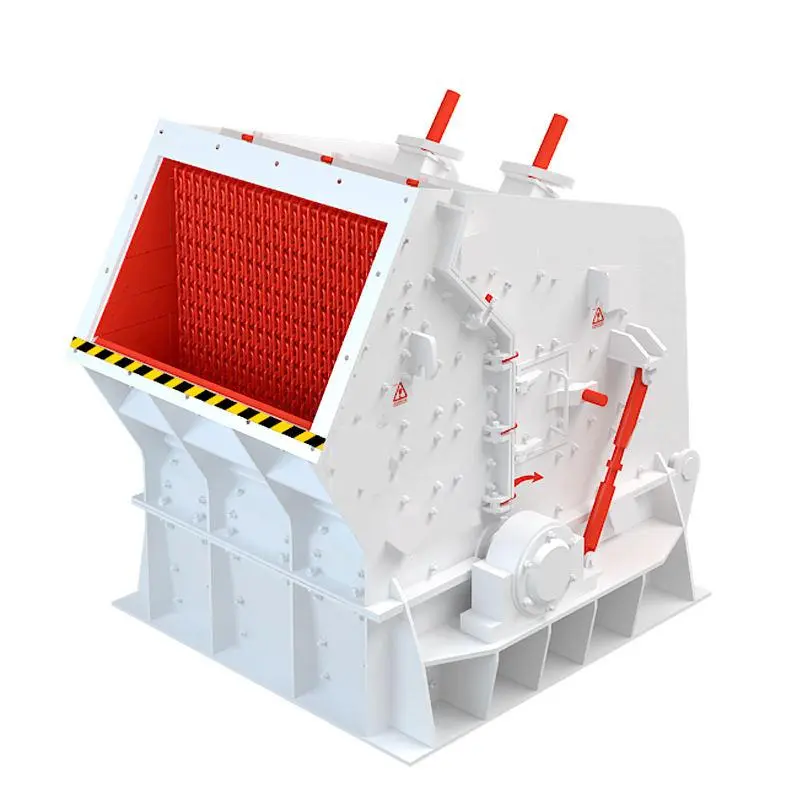

Other Crushers

Online Consultant

Forui Machinery, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. Don’t hesitate to Contact Us, if you have any questions.