Introduction

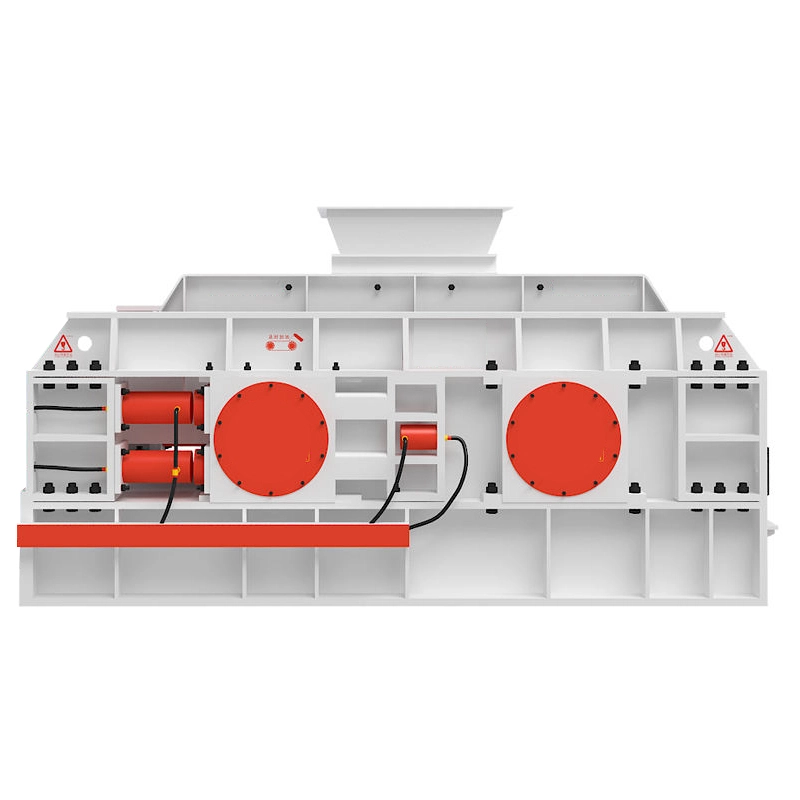

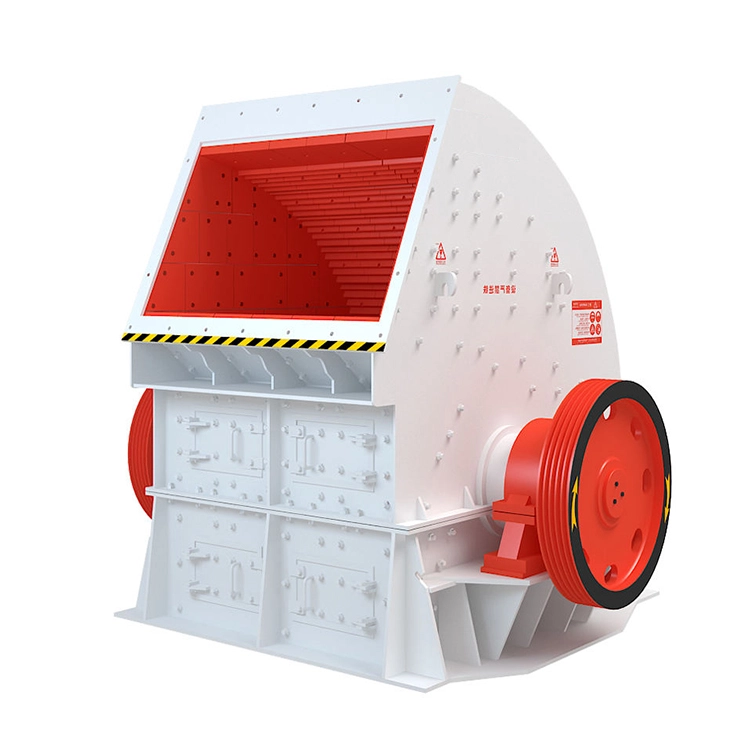

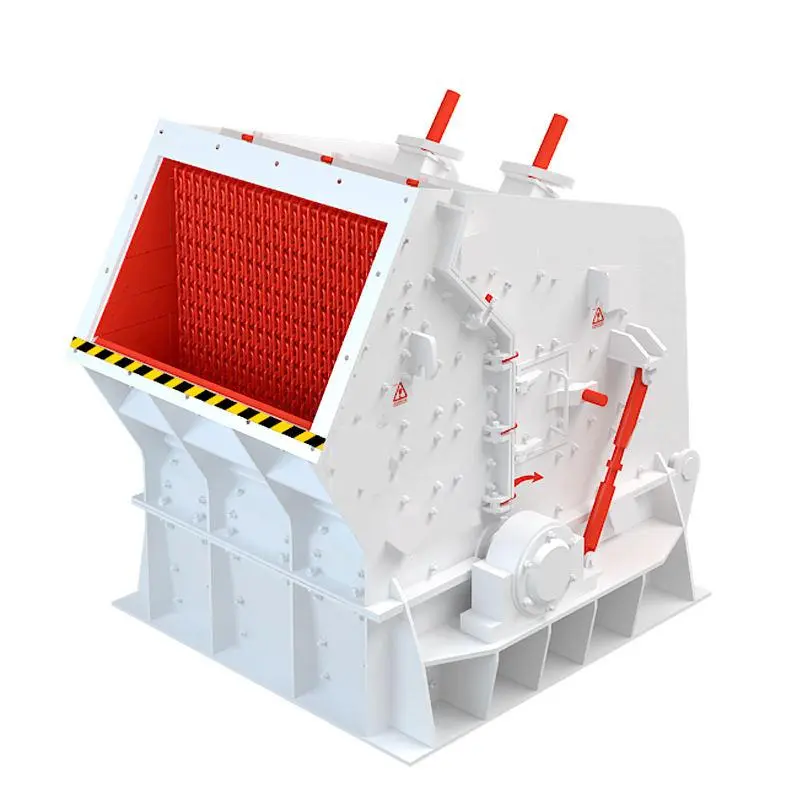

Impact crusher is a processing equipment that uses impact energy to perform secondary and tertiary crushing of medium-hard brittle materials (compressive strength not exceeding 350 MPa).

Impact crushers typically have a crushing ratio of around 20,and the processing capacity of impact crusher can reach 350T/H.

The impact crusher is suitable for fine crushing of limestone, dolomite, quartz stone and other materials. It is widely used in the secondary crushing of materials in mining, aggregate, sand and concrete industry.

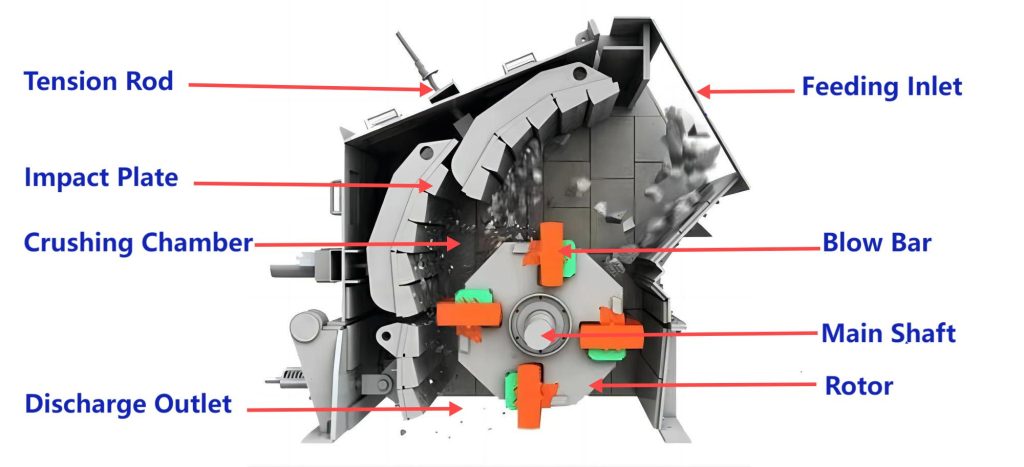

Working Principle

The impact crusher is a crushing machine that uses impact energy to crush materials. When the machine is working, driven by the motor, the rotor rotates at a high speed. When the material enters the blow bar area, it collides with the blow bar on the rotor and breaks, and then is thrown to the impact device to be crushed again, and then bounces off the impact liner. Go back to the action area of the blow bar for re-crushing. This process is repeated. The material enters the first, second and third impact chambers from large to small for repeated crushing until the material is crushed to the required particle size and discharged from the discharge port.

Features

- High quality material: The rotor, hammer plate, liner, etc. are all made of high-quality steel, which is durable; the blow bar is poured with Gaoming wear-resistant composite technology, which has a large impact resistance; brand bearings have a large load-carrying capacity.

- Excellent particle shape: Involute-type crushing cavity, three-stage crushing, self-contained shaping function; large crushing ratio, product shape is polygonal; “stone strikes iron” principle, more crushing and less grinding, low powder output rate.

- Reasonable structure: The crushing chamber is optimized, and the material passes through a large shaft; the high-precision heavy-duty rotor has a large rotating inertia, a large crushing chamber, a large space for material movement, and high crushing efficiency.

- Granularity controllable: 3 methods can effectively control the discharge particle size to meet the requirements of different users for different finished product specifications; each bonding surface of the equipment has mature technology, is firmly fixed, and operates stably.

Technical Parameters

| Model | Max Feeding Size (mm) | Rotor Size D*L(mm) | Capacity(t/h) | Power(kw) | Weight(t) |

|---|---|---|---|---|---|

| PF 0607 | 100 | 644*740 | 10-20 | 30 | 4 |

| PF 0807 | 300 | 850*700 | 20-30 | 30-45 | 8.1 |

| PF 1007 | 300 | 1000*700 | 30*50 | 37-55 | 9.5 |

| PF 1010 | 350 | 1000*1050 | 50-90 | 55-75 | 14 |

| PF 1210 | 350 | 1250*1050 | 70-130 | 110-132 | 17 |

| PF 1214 | 350 | 1250*1400 | 90-180 | 132-160 | 22 |

| PF 1315 | 500 | 1320*1500 | 120-250 | 180-260 | 26 |

| PF 1320 | 500 | 1320*2000 | 160-350 | 160-350 | 30 |

Other Crushers

Online Consultant

Forui Machinery, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. Don’t hesitate to Contact Us, if you have any questions.