Product

This solution is designed according to the practical experience of Forui Machinery in treating waste incineration slag in power plants for many years, and integrates the processes of magnetic separation, crushing, screening, jigging, dewatering, etc. The purpose is to recover useful metals such as iron, copper, aluminum, stainless steel, gold and silver from the incineration slag, and to further treat and recycle the waste slag at the same time.

Features

The main features of the waste incineration slag processing program are as follows

- Small investment in equipment, low production costs and good economic benefits.

The equipment investment of the program is very small, the daily processing capacity of 500 tons of equipment investment is only a few hundred thousand yuan, the cost of processing each ton of waste incineration slag is not higher than 5 yuan. And the daily income of recovered non-ferrous metals as well as alloys is much higher than the cost, which can generate considerable economic benefits.

- Good recycling effect and high recycling efficiency.

After many times practice, the program recovery of useful metals in waste incineration slag is very satisfactory and efficient, a small and medium-sized city to establish 3-5 such plants can be completely consumed by the power plant waste incineration slag.

- The production process is not only free of secondary pollution, but also improves the environment.

The project not only avoids the waste of useful resources, but also reduces the problem of land occupation and environmental pollution caused by waste landfills. At the same time, the production process uses recycled water without using any chemicals, which will not produce secondary pollution.

Technological Process

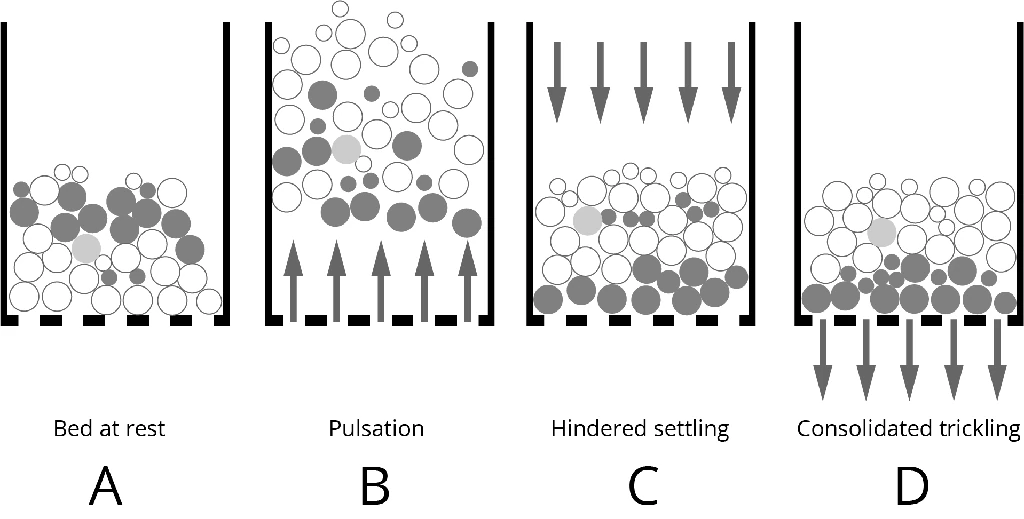

The waste incineration slag processing program integrates magnetic separation, crushing, screening, jigging and dewatering processes. We first need to carry out magnetic separation of incineration slag, which requires the use of magnetic pulleys, with the magnetic separation of pre-recovery of iron-containing materials in the incineration slag, non-iron materials into the metal crusher crushing. The crushed material is sent to the trommel screen for sieving, and after sieving into different particle sizes, it enters the jigger for gravity separation to obtain heavy minerals.

The heavy minerals then go through shaking bed sorting and manual picking to recover the copper, aluminum, gold, silver and other materials. The light minerals are then dewatered by dewatering screens and treated as raw materials for paving or cement plants. The overall equipment configuration needs to be determined according to the type of waste incineration slag, particle size, output and other conditions.

The waste incineration slag processing solution is designed by Forui Machinery based on years of practical experience in treating waste incineration slag in power plants and has strong applicability. It uses the principle and equipment of mineral processing such as magnetic separation and gravity separation to treat and recover the waste incineration slag, which can effectively recover iron, copper, aluminum, stainless steel, gold, silver and other metals.

It can not only generate considerable economic benefits, but also the waste slag can be used as raw material for paving, and there are many such cases in China at present. It is the most popular and practical processing solution in the power plant waste incineration slag processing industry, which has been put into practice in Jiangsu, Gansu, Guangdong and Shandong in China, and has obtained satisfactory results.

Client Case

Online Consultant

Forui Machinery, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. If you have any questions, feel free to Contact Us.