Online Consultant

As a kind of weakly magnetic iron ore, the beneficiation method of specularite is similar to that of hematite and limonite, which mainly includes gravity beneficiation method, magnetization roasting and magnetic separation method. Among them, gravity beneficiation method has various advantages such as energy saving, high efficiency and environmental protection, so gravity beneficiation production line is most widely used in specularite beneficiation.

Technological Process

Specularite is mostly coarse-grained embedded, with obvious boundaries between iron minerals and veinlets, and the specific gravity difference between iron minerals and veinlets is obvious, which is very suitable for gravity beneficiation method. Gongyi Forui Machinery Factory has carried out the beneficiation and purification for specularite in Hainan and Xinjiang, and all of them have obtained high beneficiation index, which is well reflected by customers.

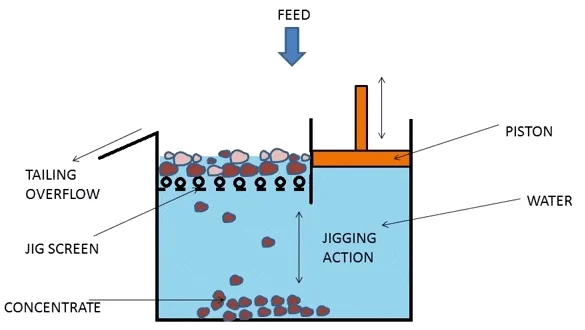

Specularite beneficiation production line is mainly composed of jaw crusher, cone crusher, vibrating screen, conveyor, silo, feeder, trapezoidal jigger, large particle jigger, dewatering screen and other equipment. The raw ore is coarsely crushed by the jaw crusher and then fed into the cone crusher for fine crushing, and the finely crushed material is sent to the vibrating screen for screening, and the material that meets the size requirement is fed into the jigger for beneficiation. The concentrate and tailings from the jigger enter the dewatering screen respectively and then transported to the stockyard.

Client Case

- Hainan specularite beneficiation production line site

Hainan specularite beneficiation production line mainly adopts 2LTC-912/4 jigger to process 10-50mm coarse grained specularite and 2LTC6109/8T jigger to process 0-10mm medium and fine grained specularite, this specularite beneficiation production line consists of jaw crusher, cone crusher, 16 sets of 2LTC-912/4 jigger, 4 sets of AM30 jigger and 4 sets of 2LTC6109/8T jigger. The production line can complete the production of 10,000 tons of specularite per day with the grade of 32%-40% of raw ore and 55%-58% of concentrate after jigger sorting.

- Xinjiang specularite beneficiation production line site

Xinjiang specularite beneficiation production line mainly adopts the process flow of coarse crushing by jaw crusher, fine crushing by hammer crusher, gravity separation by jigger, and dewatering by dewatering screen. The production line can process 0-50mm coarse, medium and fine grained specularite, and can complete the beneficiation of 2,000 tons of iron ore per day, with a raw ore grade of about 45%, and the concentrate grade after jigger sorting can reach more than 62%, and the recovery rate is 86%.

Online Consultant

Forui Machinery, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. If you have any questions, feel free to Contact Us.