Introduction

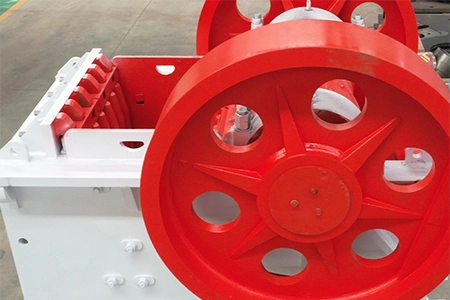

Jaw crushers typically have a crushing ratio of 3 to 5 and are used for primary crushing. They are mainly suitable for handling high-hardness rocks such as pebble, granite, basalt, and ores.

The Jaw crusher is mainly used as coarse crusher and medium crusher in mines, aggregate, building, other industry. There are three kinds according to the width of feeding port: large, medium and small. The width of feeding port is more than 600 MM for large jaw crsuher, the width of feeding port is 300-600 MM for medium jaw crusher, and the width of feeding port is less than 300 MM for minicomputer. It has simple structure, easy manufacture and reliable work.

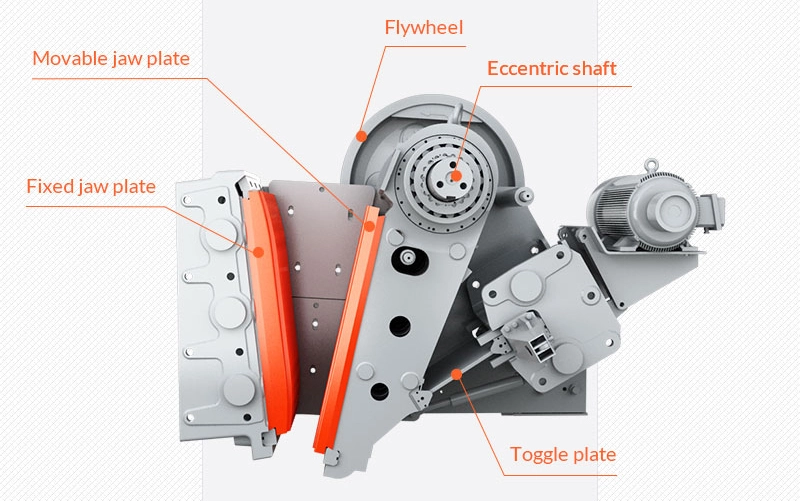

Working Principle

The working mode of jaw crusher is grinding and extrusion. Its working principle is: through the eccentric wheel to move jaw up and down, when the jaw rises to the fixed jaw plate close, and at the same time the material is crushed or split; When the moving jaw goes down, the Angle between the elbow plate and the moving jaw becomes smaller, the moving jaw plate leaves the fixed jaw plate under the action of the pull rod and the spring.

When feeding the jaw crusher, the material is poured into the crushing chamber containing the jaw teeth from the top entrance, and the jaw teeth push the material to the wall of the chamber with great force and break it into smaller stones.

Features

- Low noise and less dust.

- Its crushing ratio is large, the product particle size is uniform.

- Structure is simple, work is reliable, operation cost is low.

- Lubrication system is safe and reliable, parts replacement is convenient, equipment maintenance is simple.

- The broken cavity is deep and has no dead zone, the feed capacity and output are improved.

- Equipment energy saving: single machine energy saving 15~30, system energy saving more than double.

- Discharge port adjustment range is large, can meet the requirements of different users.

Technical Parameters

PE series and PEX series.These two kinds of Jaw Crushers both have the features of high crushing and even product size ratio.

PE Series is used in primary crushing, while PEX series is used in secondary crushing and fine crushing.

| Model | Max Feed Size(mm) | Discharge Size(mm) | Capacity(t/h) | Power(kw) | Weight(t) | Dimension(mm) |

|---|---|---|---|---|---|---|

| PE-150×250 | 130 | 10-40 | 1-5 | 5.5 | 0.4 | 875×756×850 |

| PE-250×400 | 210 | 20-80 | 5-21 | 15 | 2.6 | 1450×1315×1296 |

| PE-400×600 | 350 | 40-100 | 16-65 | 30/37 | 6.5 | 1565×1732×1586 |

| PE-500×750 | 425 | 50-100 | 45-100 | 55 | 10.1 | 1890×1916×1870 |

| PE-600×900 | 500 | 65-160 | 90-180 | 55/75 | 15.5 | 2305×1840×2260 |

| PE-750×1060 | 630 | 80-140 | 110-320 | 110 | 28 | 2450×2472×2840 |

| PE-800×1060 | 650 | 100-200 | 140-350 | 110 | 28.5 | 2450×2556×2800 |

| PE-870×1060 | 670 | 200-260 | 140-380 | 110 | 30.5 | 2660×2556×2800 |

| PE-900×1200 | 750 | 100-200 | 180-360 | 132/160 | 50 | 3335×3182×3025 |

| PE-1000×1200 | 850 | 192-260 | 200-420 | 132/160 | 51 | 3435×3182×3025 |

| PE-1200×1300 | 1000 | 180-330 | 400-800 | 220 | 62 | 4538×2984×3959 |

| PE-1200×1500 | 1020 | 150-350 | 400-800 | 220 | 100.9 | 4200×3732×3025 |

| PE-1500×1800 | 1200 | 220-350 | 450-1000 | 280 | 122 | 5100×4700×4300 |

| PEX-250×1000 | 210 | 25-60 | 16-52 | 30/37 | 6.5 | 1530×1992×1380 |

| PEX-250×1200 | 210 | 25-60 | 20-60 | 37 | 7.7 | 1900×2192×1430 |

| PEX-300×1300 | 250 | 25-90 | 20-90 | 55 | 11 | 2200×2360×1730 |

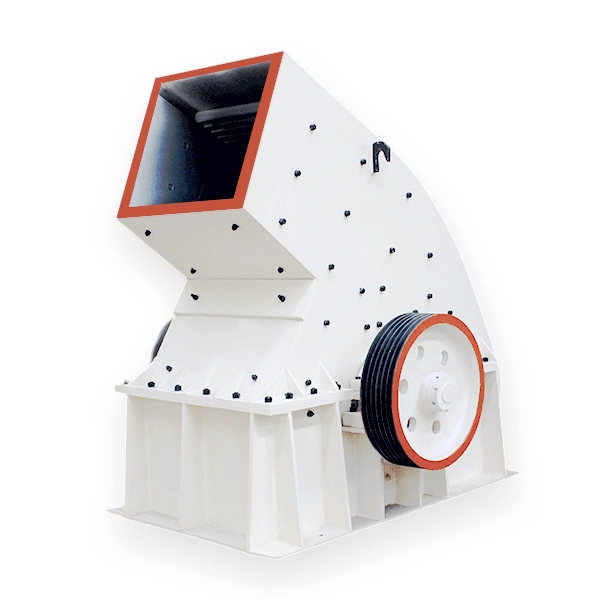

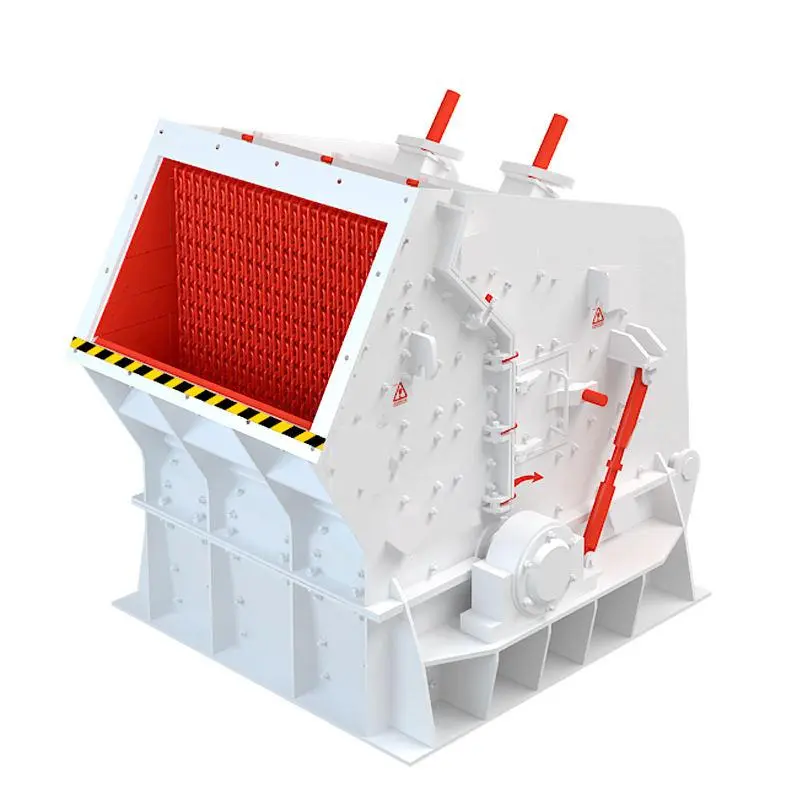

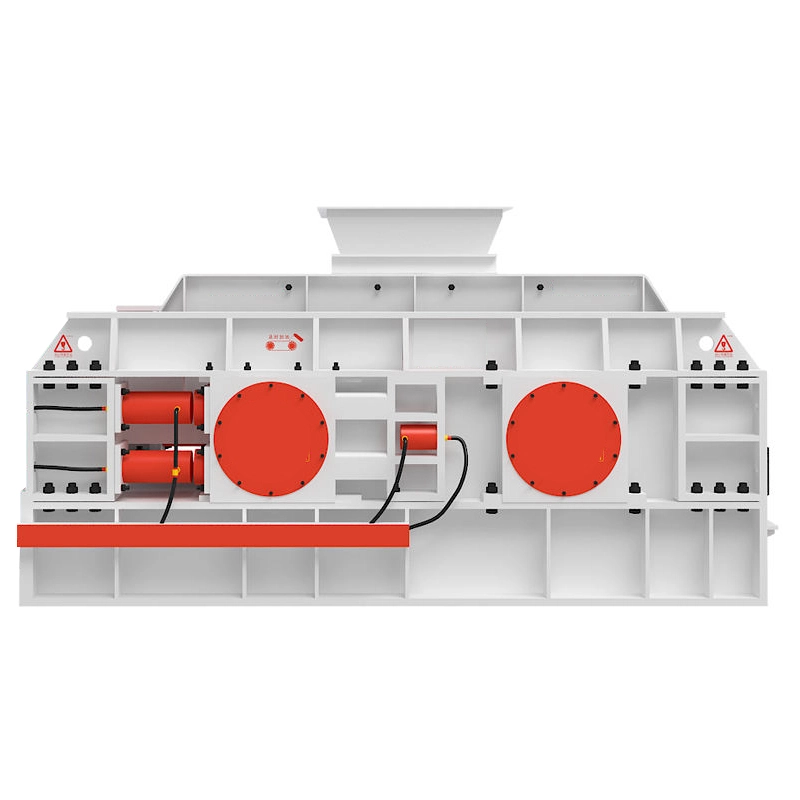

Other Crushers

Online Consultant

Forui Machinery, founded in 1986. We are one of the leading suppliers of crushers and beneficiation equipments in Asia. Don’t hesitate to Contact Us, if you have any question of beneficiation.