Online Consultant

The JT serise Jig Machine (Sawtooth Wave Jigging machine) is an efficient, energy-saving, and environmentally friendly mineral processing equipment primarily used for fine particle mineral separation. It utilizes a cam-driven mechanism to generate a sawtooth wave pulsation curve, ensuring a steady upward water flow and a rapid downward flow. This enhances the suction effect during the jigging process, significantly benefiting the recovery of fine minerals.

Applicaiton

The JT serise Jig Machine (Sawtooth Wave Jigging machine) is mainly used for the separation of various minerals, including tungsten, tin, gold, iron, manganese, titanium, molybdenum, chromium, and sulfur. It is also effective for recovering alloy particles from metallurgical slag, such as manganese, chrome, and stainless steel slag, as well as for metal recovery from mine tailings and tailings treatment.

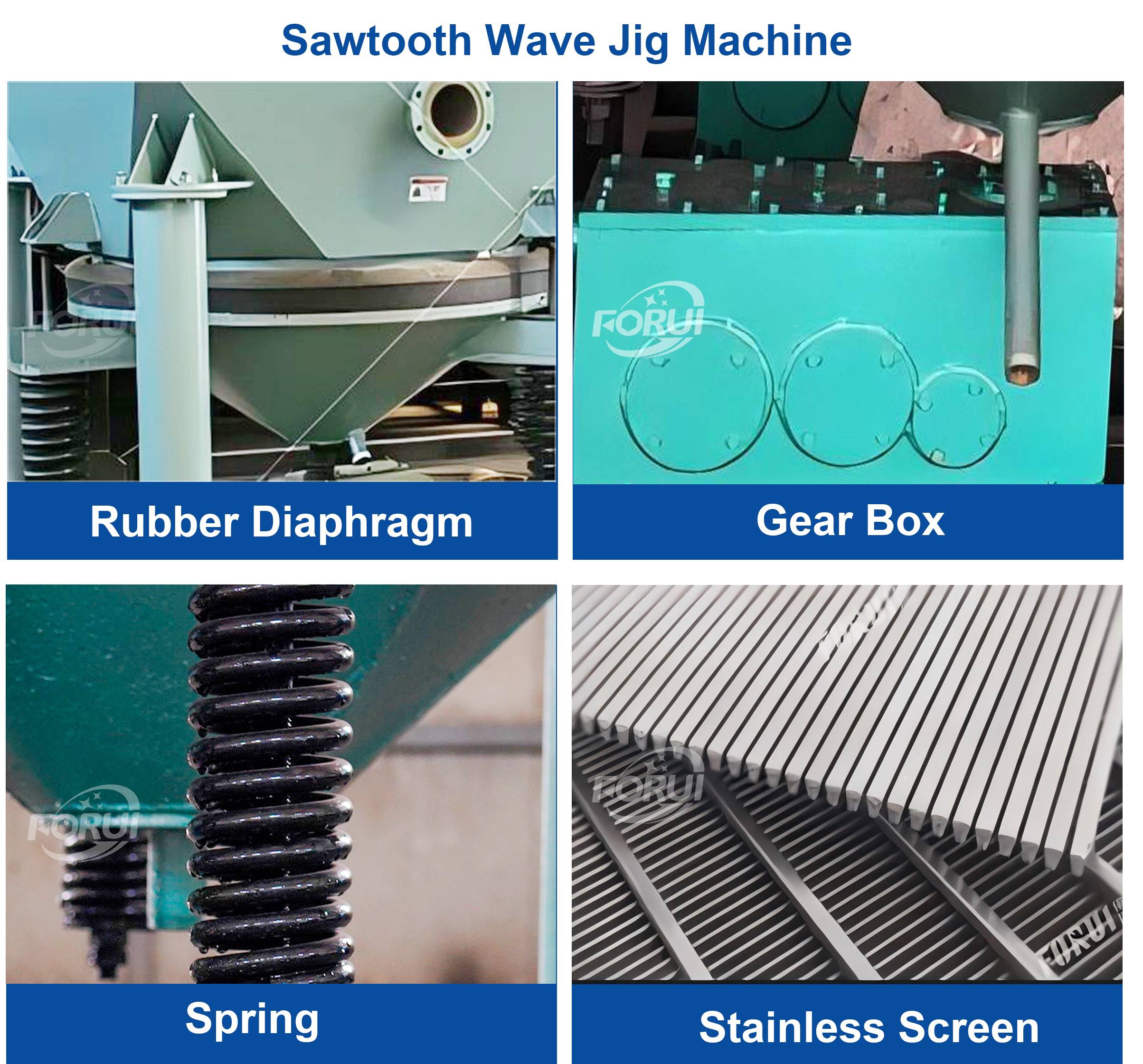

Product Features

Optimized Structure:

The bottom-driven design occupies less space while maximizing processing capacity per unit area.

Efficiency Transmission:

The cam mechanism produces a sawtooth wave pulsation, with a faster upward water flow compared to the downward flow, enhancing separation effectiveness for particles smaller than 5mm.

Energy and Water Saving:

Reduces water consumption by 30-40%.

User-Friendly Operation:

Easy adjustment of stroke and frequency, along with simple installation and maintenance.

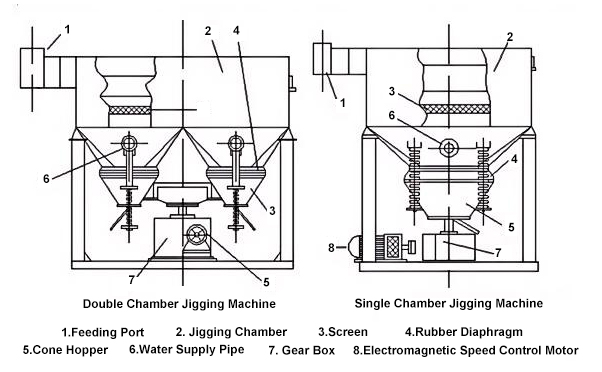

Working Principle

The JT jigging machine consists of a feeding port, jigging chamber, screen mesh, rubber diaphragm, cone hopper, water supply pipe, gear box, and electromagnetic speed control motor. The driving diaphragm is located beneath the jigging chamber. During operation, the electromagnetic speed control motor drives the cam, which, in conjunction with a spring, moves the cone hopper and diaphragm up and down. This action generates a sawtooth wave water flow within the tank. The concentrate is collected through the concentrate pipe located below the cone hopper, while the tailings are discharged through the tailings hopper at the top of the tank, enabling continuous mineral discharge.

Technical Parameters

| Model | Feeding Size(mm) | Capacity(T/h) | Power(kW) | Chamber No. |

|---|---|---|---|---|

| JT 1070/2 | 0-5 | 6-8 | 3 | 2 |

| JT 1515/2 | 0-5 | 16-24 | 4*2 | 2 |

| JT 2020/2 | 0-10 | 25*40 | 5.5*2 | 2 |

Online Consultant

To find out more about our products and solutions, please fill out the form below and we will get back to you shortly.