Online Consultant

The products of mercury ore are mainly mercury and cinnabar, which are mainly used to produce mercury in China, and cinnabar is used in chemical and pharmaceutical applications. Cinnabar is a red mercury sulfide mineral with specific gravity 8.1-8.2 and good floatability, and the beneficiation methods are mainly gravity beneficiation and flotation, and sometimes a combined gravity beneficiation-flotation process is also used.

Technological Process

Mercury ore beneficiation process is mainly divided into gravity beneficiation process, flotation process, and combined gravity beneficiation-flotation process.

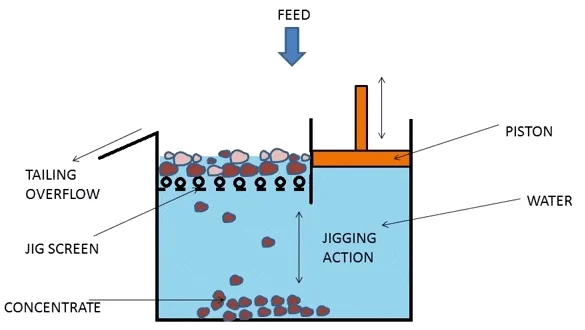

- Mercury ore gravity beneficiation process is: crushing – screening – jigging – shaking table.

- Mercury ore flotation process is: crushing – screening – grinding – classification – agitation – flotation – press filter.

- The combined mercury ore gravity beneficiation-flotation process is: crushing – screening – gravity beneficiation – dewatering – grinding – classification – agitation – flotation – filter press.

The structure of mercury ore is complex, with grained embedded , speckled and lumpy forms. For massive mercury ores, a single gravity separation can achieve high beneficiation index. For speckled mercury ore, high beneficiation index can be obtained by flotation. For speckled low-grade mercury ore, a combined gravity beneficiation-flotation process can be used for beneficiation. Let’s look at a set of photos of mercury ores together:

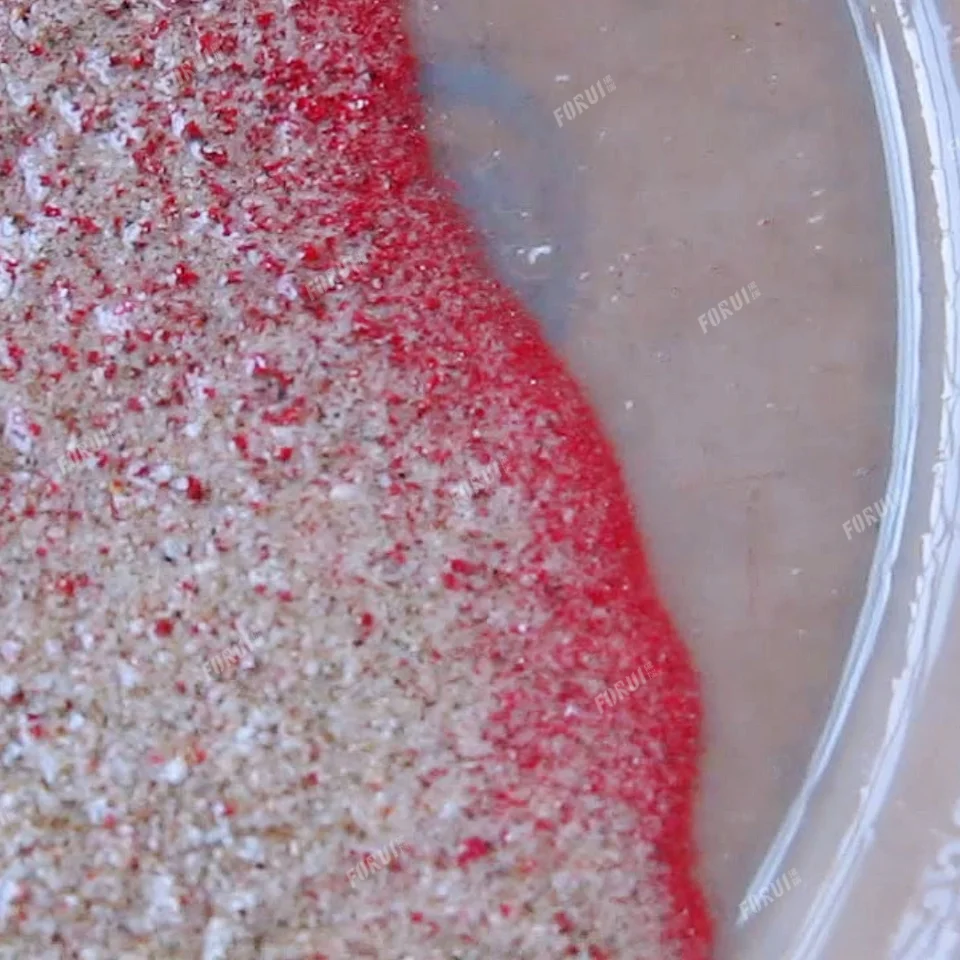

The pictures show three different types of mercury ores, among which the lumpy and coarse-grained embedded mercury ores are very simple to be beneficiated, and good beneficiation indexes can be obtained by hand separation as well as gravity separation. The fine-grained embedded mercury ore requires grinding to break the conglomerate in order to extract the mercury minerals as they are grained embedded with the waste rock. After grinding, the size of the mercury minerals is so fine that it cannot be processed by gravity beneficiation, and can only be purified by flotation with high investment in equipment and high operating costs. In order to reduce production costs and improve the beneficiation index, a combined gravity beneficiation-flotation process is also used for speckled mercury ores. The gravity beneficiation process discards a large amount of waste rock in advance to ensure the recovery rate, reduce the cost of subsequent grinding and flotation, and improve the efficiency of the subsequent process. Flotation is used to purify the crude concentrate of gravity beneficiation to get the final product, and this process is most suitable for speckled mercury ore.

Video showing the effect of mercury ore beneficiation by jigger:

Hand sorting method is sorting according to the difference in color, shape and other characteristics between mercury ore and waste rock, it has the characteristics of low production cost and high concentrate grade; however, it cannot be used for the beneficiation of medium and fine grained mercury ore, and the beneficiation index is not stable, and the labor intensity of workers is large.

Gravity separation method is suitable for processing speckled mercury ore and coarse-grained embedded mercury ore, which has the advantages of high beneficiation efficiency, small investment in equipment, low operating cost and no pollution to the environment; the disadvantage is that the recovery rate is low for fine-grained grained embedded mercury ore.

The flotation method is mainly used to extract the grained embedded mercury ore. Due to the high floatability of mercury sulfide ore, the flotation can often achieve high beneficiation index, and the purity and recovery of the concentrate can reach the ideal requirements, but the investment in equipment is large, the operating cost is high, and there is also a certain degree of pollution to the environment.

Client Case

Online Consultant

Forui Machinery, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. If you have any questions, feel free to Contact Us.