To effectively separate materials based on density, particularly when the density difference is minimal, a simple counterflow motion is often insufficient. A vertically pulsating flow through the material bed is crucial to enable proper stratification. Forui pulsator jigs are engineered to achieve this, separating light and heavy components from various feed materials such as sand, gravel, slag, demolition debris, contaminated soil, raw ore,smelting slag and solid waste.

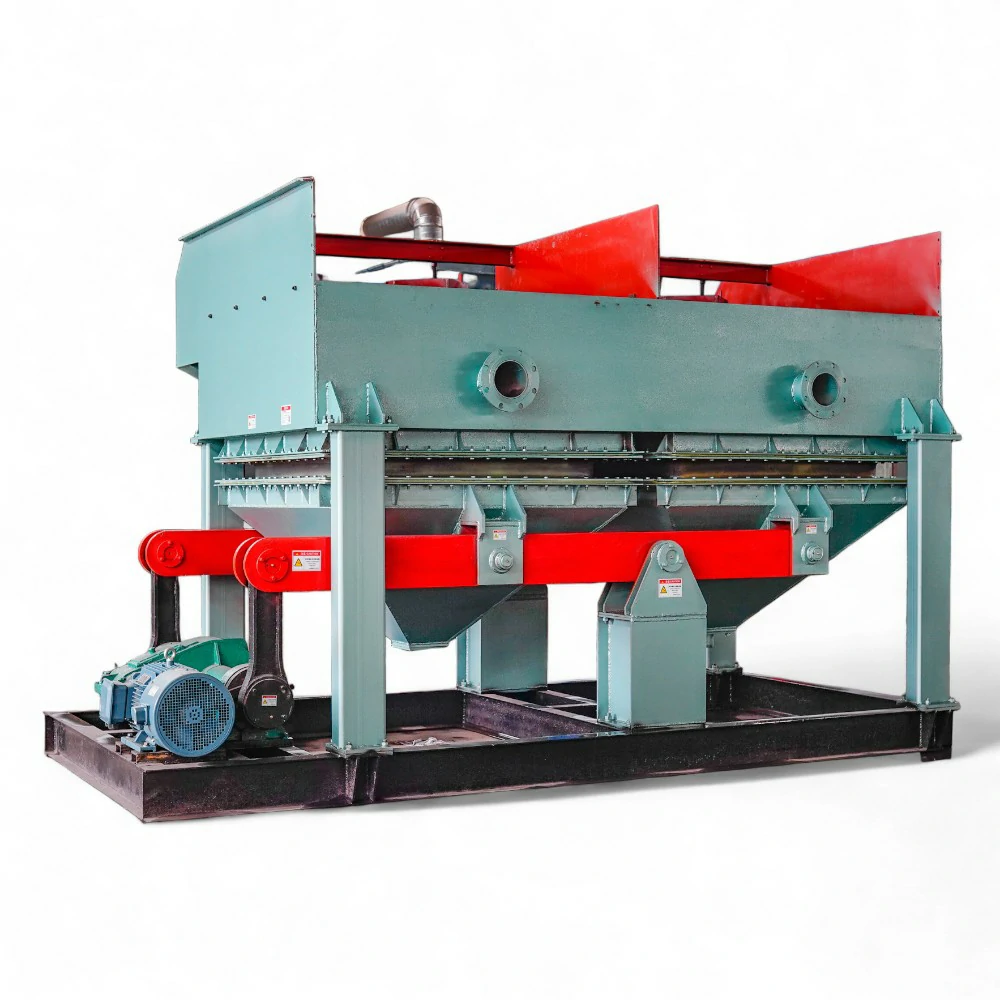

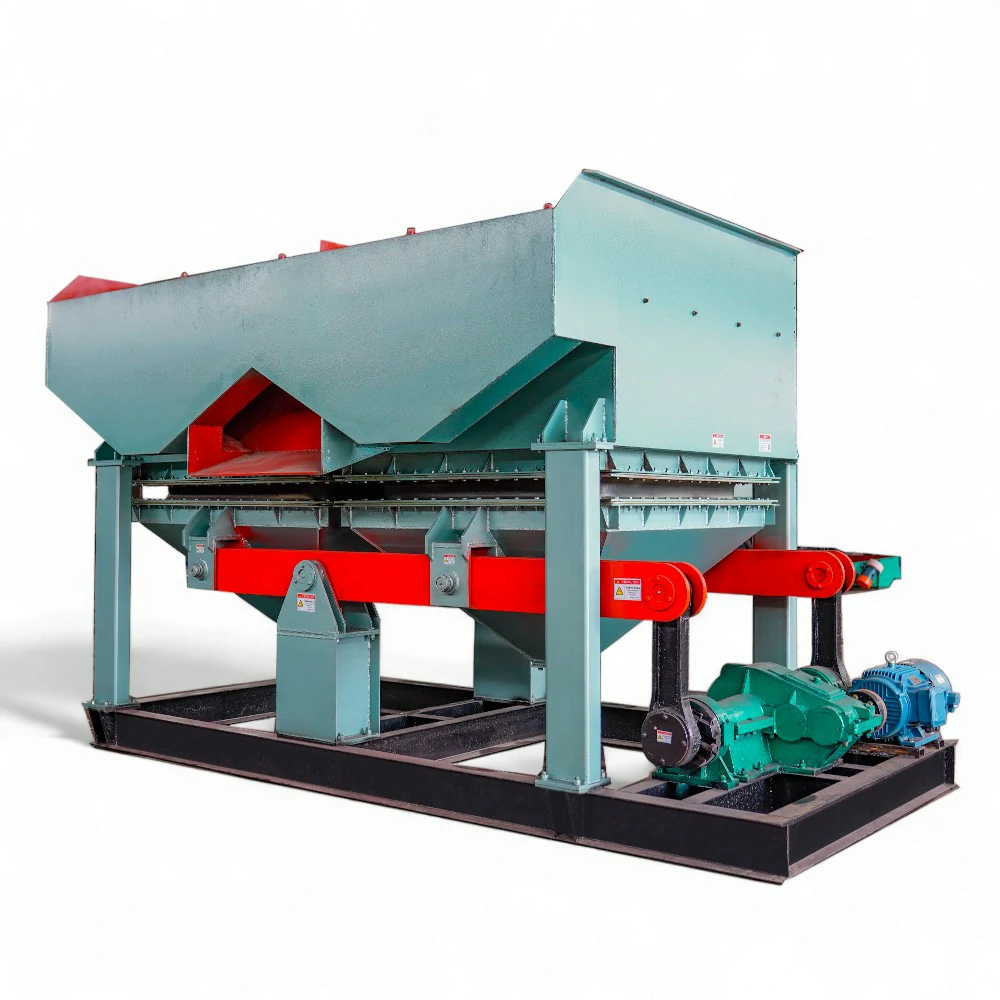

Click the image to view detailed specifications of our jigging equipment.

mineral processing industry

solid waste recycling industry

In the mineral processing industry, pulsator jigs are indispensable tools that demonstrate remarkable proficiency in recovering coarse heavy minerals, encompassing precious metals like gold and platinum, gemstones such as diamonds and sapphires, and essential minerals iron, manganese, barite, fluorite, and garnet, among others.Our FRT series jigs offer a wide size range, capable of processing minerals from 0 to 50 mm without the need for screening, significantly improving production efficiency.

In the realm of recycling, pulsator jigs showcase extraordinary capabilities. They efficiently recover metals from waste materials, enhancing resource utilization. Furthermore, they shine in the recovery of smelting slags like steel slag, stainless steel slag, and silico-manganese alloy slag, extracting and reclaiming alloy components. This not only mitigates environmental pollution but also generates considerable economic value, contributing significantly to circular economy and sustainable development efforts.

Woking Principle

The pulsator jig feeds the selected material onto its screen plate, forming a dense material layer known as the bed layer. At the same time as the material is being fed, a periodic alternating water flow is introduced through the screen plate from the bottom of the pulsator jig, and the material is separated by the action of the water flow.

Firstly, under the action of the rising water flow, the bed layer becomes gradually loose and suspended. At this point, the ore particles within the bed layer move relatively to each other according to their own characteristics (density, size, and shape) to form layers. After the rising water flow ends, during the resting period and the descending water flow period, the bed layer becomes gradually compact and continues to layer. Once all the particles have settled back onto the screen surface, the bed layer returns to a compact state. At this point, most of the ore particles have lost the possibility of relative motion, and the layering action almost completely stops. Only the extremely fine particles can continue to move downward through the gaps in the bed layer and continue to layer.

When the descending water flow ends, the layering process temporarily comes to an end. At this point, one cycle of the pulsator jig layering process is completed.

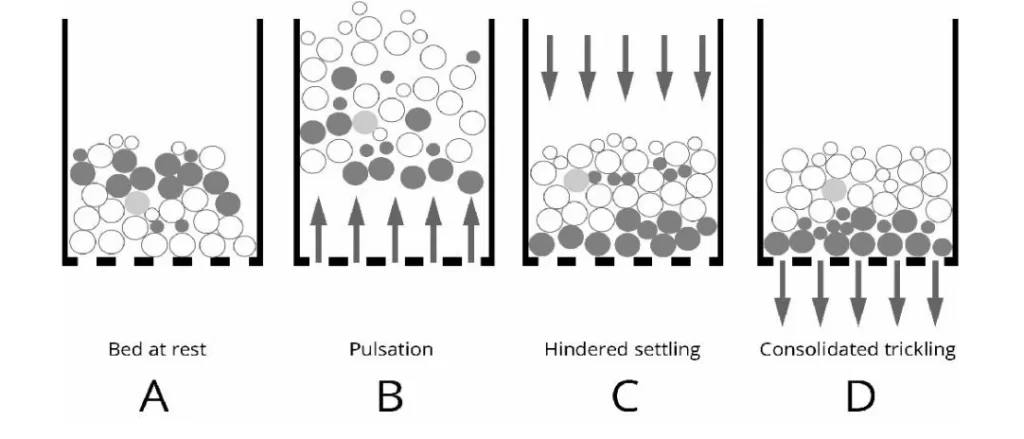

The layering process of the material during one pulsator jig cycle is shown in the figure . In each cycle, the material can only be subjected to a certain degree of separation. After multiple repetitions, the layering gradually becomes more refined. Finally, the particles with low density concentrate at the top layer, while the particles with high density concentrate at the bottom layer.

The stratification process of particles during jigging

(a) Particles are mixed and accumulated before stratification;

(b) The rising water flow lifts the bed layer;

(c) Particles settle and stratify in the water flow

(d) As the water flow descends, the bed layer becomes dense, and heavy minerals move to the bottom layer.

Advantages

Low Equipment Investment: The initial investment for pulsator jigs is relatively low, with comparatively fewer equipment costs. Coupled with their high efficiency, energy-saving features, and low maintenance, the overall investment and operating costs are low, making them economically advantageous.

Large Processing Capacity: Pulsator jigs are well-suited for large-scale production and can be adjusted to handle significant volumes. Their design supports continuous operation, ensuring consistency and stability in the production process.

Low Energy Consumption: Compared to other separation equipment like flotation machines and magnetic separators, pulsator jigs consume less energy. They primarily rely on the pulsating action of water and gravity, resulting in relatively low electrical power consumption and higher economic efficiency.

Simple Operation: Pulsator jigs have a relatively simple structure, making them easy to operate and maintain. High-efficiency separation can be achieved by merely adjusting the pulsation frequency and intensity of the water flow, without the need for complex technology or equipment.

Environmental Advantages: Pulsator jigs do not require chemical reagents during operation, thus avoiding environmental pollution caused by chemicals. Their separation process primarily depends on physical actions, minimizing environmental impact and aligning with green mining and sustainable development principles.

Strong Adaptability: Pulsator jigs can handle various types of minerals and coal, demonstrating strong adaptability. Whether dealing with metallic minerals, non-metallic minerals, or coal, effective separation can be achieved by adjusting the machine’s parameters accordingly.

High Separation Precision: By adjusting the pulsation frequency and intensity of the water flow, pulsator jigs can achieve high separation precision. This ensures high-grade concentrates and low-grade tailings, enhancing resource utilization and economic benefits.

Low Maintenance Costs: Due to their simple structure and durable key components, pulsator jigs have low maintenance costs. Regular inspections and maintenance are sufficient to ensure long-term stable operation, reducing downtime and maintenance expenses.

Suitable for Various Particle Sizes: Pulsator jigs can process materials ranging from fine to coarse particles, offering a wide range of applications. Effective separation of different particle sizes can be achieved by selecting the appropriate screen and pulsation parameters.

We can ship you parts, send field service technicians to your site and answer any questions you have. Whatever you need, we are here for you.

Reviews

There are no reviews yet.