Introduction

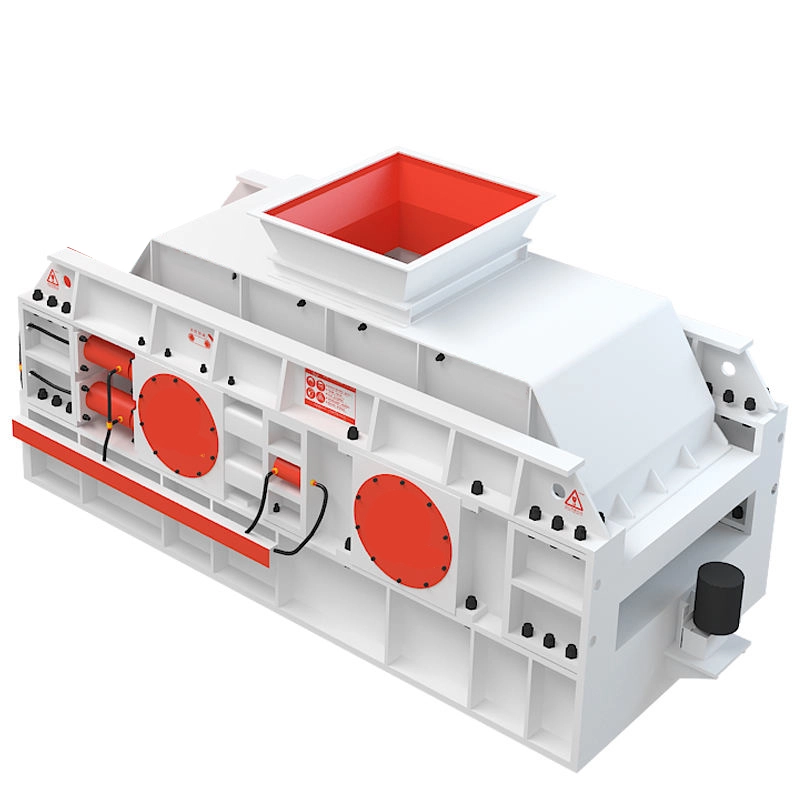

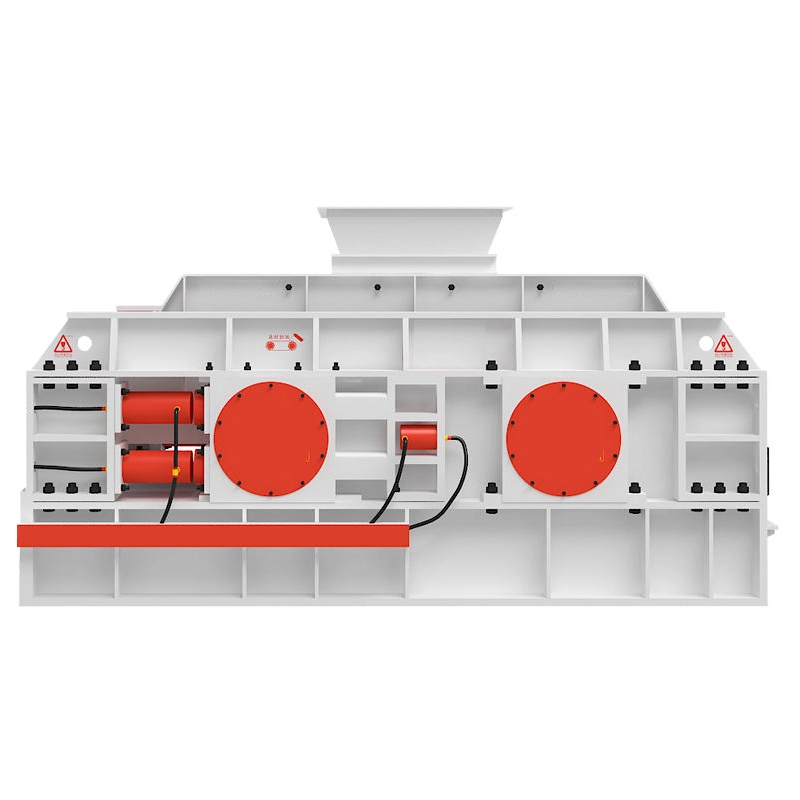

Roller crusher has a crushing ratio of 5 to 8 and are used for fine crushing. It has a wide range of feed particle sizes, up to 130mm, and the discharge size is 2-45mm. The roller crusher is designed to handle the secondary and tertiary stage crushing of friable materials such as coal, salt, bauxite, limestone, barite and other minerals withstand crushing strength ≤160 MPa in the mining, power generation, recycling and other industries

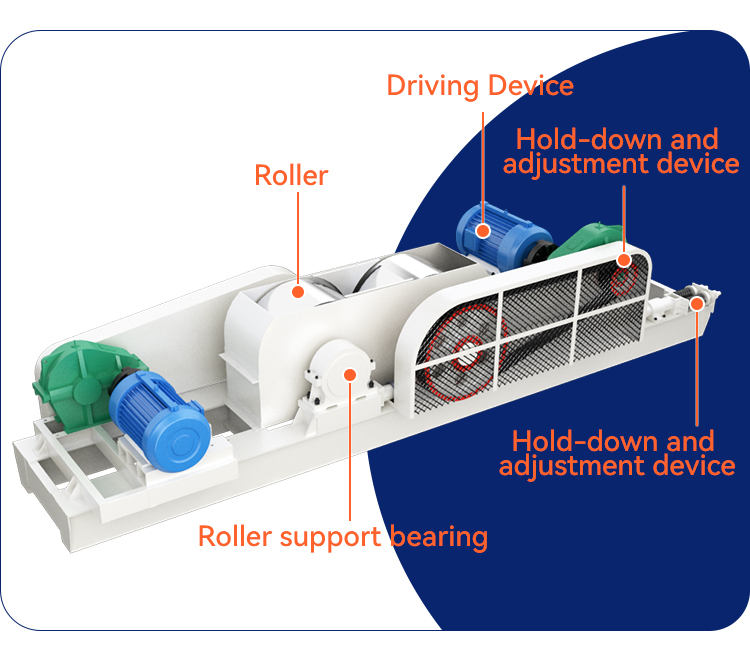

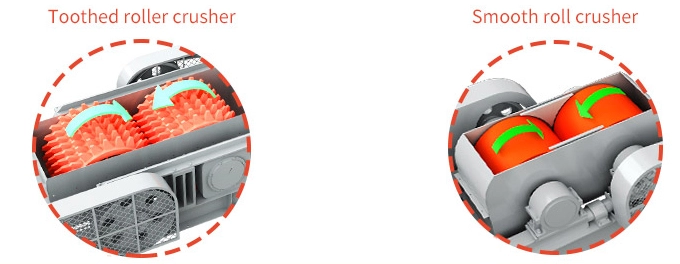

Forui roller crusher uses two rotating rollers to crush the material. It consists of motor, rotor, flywheel, belt and buffering spring. Two roller surfaces -Smooth roller and tooth roll, which can be selected and combined according to the granularity required by users.

Working Principle

Double Roller Crushers are simple in design and construction. These machines are long-lasting, economical, and versatile across many applications and industries. Impact, shear, and compression are necessary for crushing and size reduction.

The material enters the crusher and is impacted by the roll as it rotates. Then, shear and compression forces act upon the material as it’s pulled between a crushing plate or rolls. The crushing rolls on these machines act as flywheels, contributing to the smooth, continuous operation and efficient use of power. Roll crushing surfaces operate at a fixed distance apart, unlike the continually changing distances in a jaw or cone crusher. The result of using this equipment is a more consistent product size.

Features

- The roller is wear-resisting chromium molybdenum copper alloy with long service.

- The gap between the rollers is adjustable, so that the output size and capacity will be changed accordingly.

- This crusher is equipped with motorless scraper. When the raw material has high moisture content, it can avoid to affect the output size and avoid sticking the roller or blocking the machine.

- According to requirement, it could be in smooth roller or toothed roller.

Technical Parameters

| Model | Max Feed Size (mm) | Discharge Size(mm) | Capacity(t/h) | Power(kw) | Weight(t) |

|---|---|---|---|---|---|

| 2PG 400*250 | 25 | 0-8 | 2-8 | 2*5.5 | 1.3 |

| 2PG 400*400 | 25 | 0-8 | 5-12 | 2*7.5 | 2.3 |

| 2PG 600*500 | 65 | 0-20 | 10-15 | 2*15 | 4.3 |

| 2PG 750*500 | 75 | 0-25 | 10-40 | 2*18.5 | 9.5 |

| 2PG 800*600 | 80 | 0-25 | 12-45 | 2*22 | 10.8 |

| 2PG 1000*700 | 100 | 0-30 | 20-65 | 2*30 | 14.9 |

| 2PG 1200*800 | 120 | 0-35 | 35-80 | 2*37 | 25.5 |

| 2PG 1500*1000 | 130 | 0-45 | 50-120 | 2*75 | 33.7 |

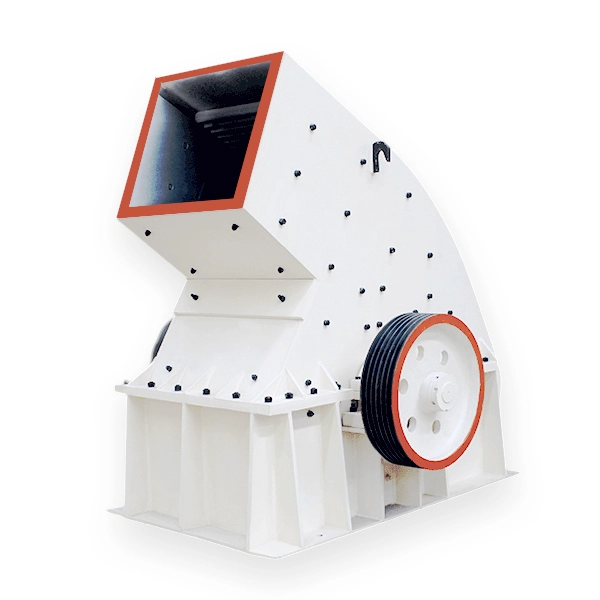

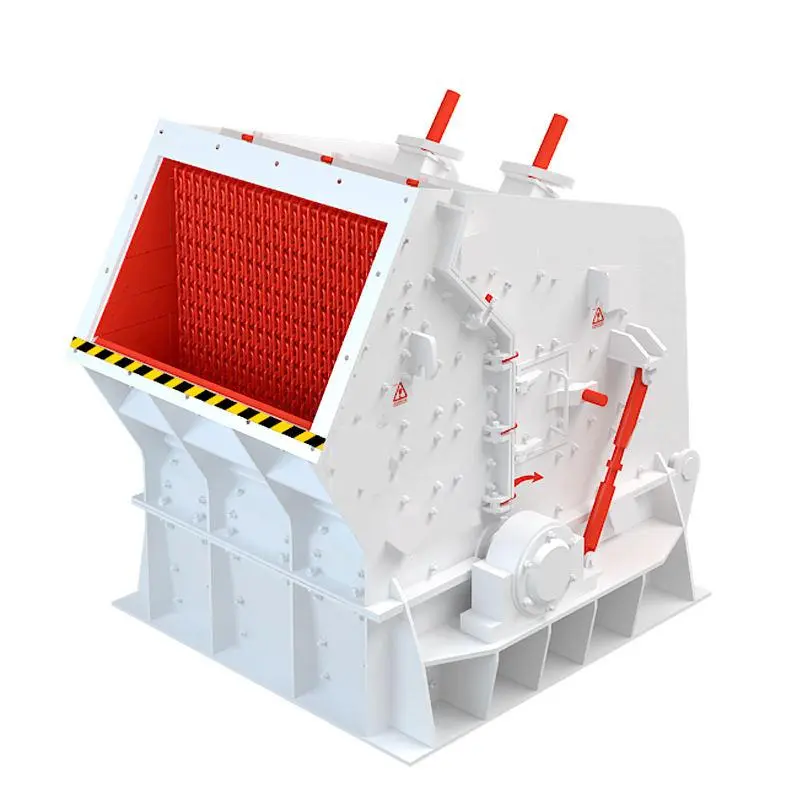

Other Crushers

Online Consultant

Forui Machinery, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. Don’t hesitate to Contact Us, if you have any questions.