Introduce

1

1

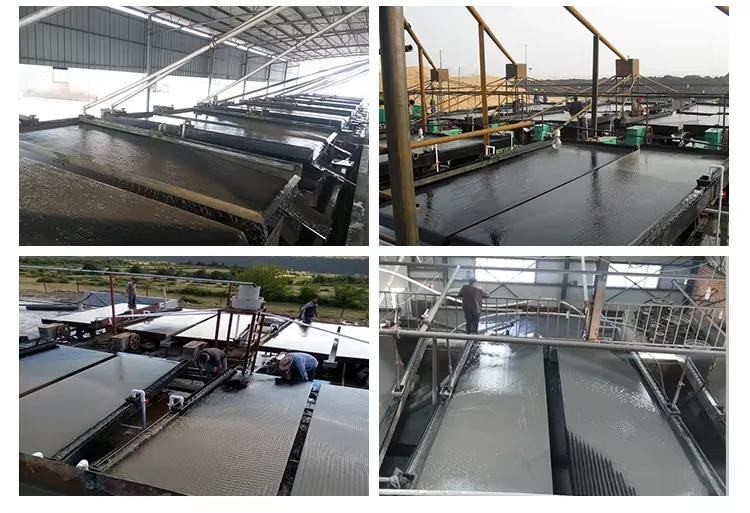

The gold shaker table is a widely used mineral sorting equipment,. It is especially suitable for the separation of heavy minerals such as gold, silver, tin, tantalum, niobium, tungsten, manganese, lead, zinc, and iron. It separates mineral particles based on their density and size differences through vibration and water flow action.

Features

Simple Structure: The shaker table has a relatively simple structure, mainly consisting of a table surface, a frame, and a transmission mechanism, which is easy to operate and maintain.

Wide Adaptability: The shaker table can process a variety of minerals with a wide range of particle sizes, from coarse to fine, and can effectively separate them.

High Efficiency: The shaker table has a high separation efficiency and recovery rate, and can effectively recover valuable minerals.

High Enrichment Ratio: The shaker table can obtain high-grade concentrates, improving the utilization value of minerals.

Easy Adjustment: By adjusting the inclination angle of the table, stroke, and stroke frequency, it can adapt to the separation requirements of different minerals.

外观图_00.webp)

Application Areas

Non-ferrous metal ore dressing: Widely used in the beneficiation of non-ferrous metal ores such as copper, lead, zinc, gold, and silver.

Ferrous metal ore dressing: Can be used for the beneficiation of ferrous metal ores such as iron and manganese.

Rare metal ore dressing: Suitable for the beneficiation of rare metal ores such as tungsten and tin.

Non-metallic mineral ore dressing: Can be used for the beneficiation of non-metallic minerals such as quartz and calcite.

Advantages

High Separation Accuracy: The shaker table can effectively separate minerals with different specific gravities and obtain high-purity concentrates.

Easy Operation: Simple operation and maintenance, requiring no complex training.

Low Cost: Compared with other beneficiation equipment, the shaker table has a lower investment cost and operating cost.

Wide Application: The shaker table is suitable for the beneficiation of various minerals, such as gold, silver, copper, lead, zinc, tungsten, tin, etc.

Environmentally Friendly: The shaker table is a physical beneficiation method that does not use chemical reagents and causes less environmental pollution.

Working Process

Simplified Working Process:

Table Motion: The table of the shaker table is inclined and undergoes a reciprocating asymmetrical motion. This motion generates an inertial force that causes the mineral particles to stratify on the table.

Water Scouring: A transverse water flow scours the table surface, further promoting the stratification of mineral particles. Heavier minerals, due to their greater specific gravity, are less affected by the scouring force of the water and tend to settle to the lower layer of the table, while lighter minerals are more easily carried upward by the water flow.

Mineral Separation: Due to the combined action of gravity and water flow, mineral particles with different specific gravities form different mineral layers on the table. Heavier minerals gradually move toward the lower end of the table, while lighter minerals move toward the upper en

Concentrate and Tailings Discharge: Finally, the heavier minerals (concentrate) are discharged from the lower end of the table, and the lighter minerals (tailings) are discharged from the upper end of the table, thus achieving the separation of minerals.

Online Consultant

To find out more about our products and solutions, please fill out the form below and we will get back to you shortly.

| Weight | 700 kg |

|---|---|

| Dimensions | 450 × 185 × 50 cm |

| Model | 6S |

| Feed Size (mm) | 0-2 |

| Capacity (t/h) | 1-2.5 |

| Power (kw) | 1.1 |

| Brand | Forui |