Glass fiber reinforced plastics spiral concentrator is a kind of advanced gravity separation equipment with high efficiency. It is used for processing fine-grained minerals of iron, tin, tungsten, niobium, gold, coal, monazite, rutile and zircon with particle size 0.3-0.02m, as well as other metal and non-metallic minerals with obvious difference of specific gravity.

This equipment is suitable for sorting fine materials of iron ore, ilmenite, chromite, sulphide iron ore, zircon, rutile, monazite, phosphorite, tungsten ore, tin ore, tantalum ore, niobium ore and other non-ferrous metals, rare metals and non-metallic mineral objects with specific gravity difference.

Spiral Concentrator Working Principle

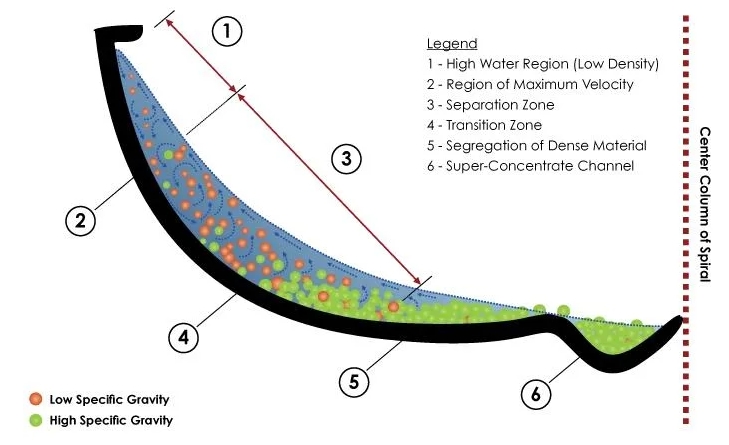

The spiral concentrator is stood up, the vertical line is calibrated and fixed in a suitable position with an iron frame or wood. The sand pump delivers the ore to the two feed ports at the top of the spiral, adds supplementary water and adjusts the concentration of the ore slurry.

The ore pulp naturally spirals downward from high, generating an inertial centrifugal force in the rotating inclined flow rate. The difference in specific gravity, particle size and shape of the ore and sand is used to separate the ore from the sand by the action of gravity and centrifugal force of the rotating flow.

The concentrate flows into the concentrate hopper and is connected by pipeline, and the tailing sand flows into the tailing sand hopper and is connected to the sand pond by pipeline, and is discharged by sand pump, completing the whole process of mineral processing.

Spiral Concentrator Features

Reasonable structure, simple installation, easy operation, less floor space

High beneficiation enrichment ratio, high recovery rate, clear separation, stable beneficiation effect

Large processing capacity, high efficiency, reliable operation, no noise

Light weight, moisture-proof, rust-proof and corrosion-resistant

Strong adaptability to fluctuations in feed quantity and concentration, particle size and grade

Spiral Concentrator Model

| Model | Screw diameter | Screw pitch | Pitch/diameter | Lateral inclination | Feed concentration | Capacity | weight |

| mm | mm | degrees | % | t/h | t | ||

| BLL-1200 | 1200 | 540-720 | 0.45-0.6-0.75 | 9 | 25-55 | 4-6 | 0.7 |

| BLL-1500 | 1500 | 675-900 | 0.36-0.48 | 9 | 30-55 | 6-8 | 0.8 |