Product

The alluvial tin beneficiation production line mainly includes trommel scrubber, spiral washer, jig machine, dewatering screen and other equipment. Due to the complex nature of tin minerals, the tin content of each alluvial tin varies, therefore, the process flow of alluvial tin beneficiation production line must be designed according to the specific nature of alluvial tin and the requirements of customers. The main beneficiation method of alluvial tin is gravity beneficiation.

Technological Process

Generally, the first step in alluvial tin beneficiation is screening. Since the vast majority of river pebbles in the alluvial tin are waste stones, the first step is to discard the waste stones. A trommel screen is usually used in the screening process, which serves to discard waste stones such as large river pebbles, and the fine sand enters the gravity beneficiation process. Some alluvial tin contain more clay, screening becomes difficult, at this time, we can use the trommel scrubber with both washing and screening functions for processing.

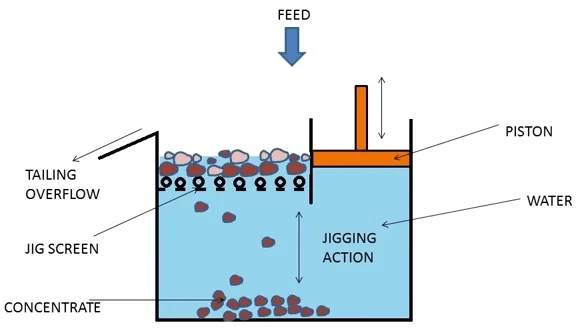

The raw ore enters the trommel scrubber to wash the ore and at the same time screen the ore into several different particle sizes. The coarse grained waste rock is discarded and the fine sand enters the spiral washer to be washed and dewatered again, and the washed and dewatered fine sand is sent to the jigger beneficiation process. The tailings after beneficiation by the jigger enter the dewatering screen and are transported to the destination site for stockpiling, and the excess water is returned to the water recycling process for continued use by the jigger.

Since the specific gravity of tin ore is much larger than that of waste sand, and the tin minerals in the alluvial tin are completely dissociated monomerically from the waste rock, the recovery effect by gravity beneficiation is very significant. At the same time, the jigger gravity beneficiation equipment has small investment, low beneficiation cost and high production capacity, it is the most ideal and scientific method for alluvial tin beneficiation.

Client Case

Cassiterite Wash Plant in Democratic Republic of the Congo

Tinstone Ore Beneficiation Plant in Rwanda

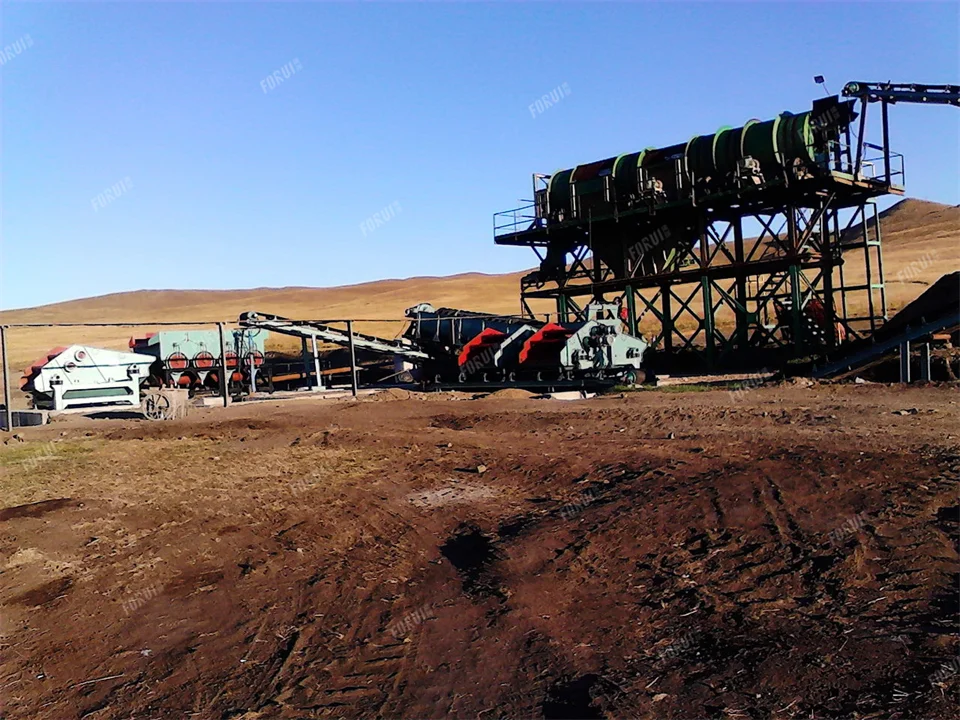

Mongolia alluvial tin beneficiation production line

Mongolia alluvial tin beneficiation production line adopts drum washer, spiral washer, trapezoidal jig machine, linear dewatering screen and other equipment to form three alluvial tin beneficiation production line, processing alluvial tin 2000m³ per day, the beneficiation effect is remarkable and highly evaluated by customers. The following is the video of the working site of Mongolia alluvial tin beneficiation production line:

Nigeria alluvial tin beneficiation production line

Nigeria alluvial tin beneficiation production line adopts the process of chute desliming, trommel screen screening, jigger gravity beneficiation, dewatering screen dewatering, processing 2000 tons per day, with remarkable beneficiation effect, which is recognized and highly praised by customers.

Russia alluvial tin beneficiation production line

Russia alluvial tin beneficiation production line adopts the process of trommel screen screening, trapezoidal jigger gravity separation, linear dewatering screen dewatering, processing 1000 tons per day, the beneficiation effect reaches the expectation, which is highly recognized by the customer.

Online Consultant

Forui Machinery, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. If you have any questions, feel free to Contact Us.