Solutions

Solutions

Sapphire Processing Plant

Sapphire, excluding ruby, is a collective term for colored corundum gemstones, primarily composed of aluminum oxide. As a mineral crystal, sapphire occurs at low concentrations

Fluorite Flotation 02:Barite-Fluorite Ore Flotation

1. Barite-fluorite Ore Flotation Process Barite-type fluorite ores primarily contain barite as a gangue mineral (usually 10-40%) and are often associated with minor sulfide minerals

Barite processing of Barite-sulfide Mineral Mixed Ore

Barite processing for barite with galena, sphalerite, and fluorite. Learn effective flotation techniques and essential equipment for barite.

High Efficiency Barite Processing Line | How To Upgrade Barite

I’ll take our barite processing line in Southeast Asia as an example to share with you how to get its high quality concentrate.

WEAKLY MAGNETIC IRON ORE PROCESSING PLANT AND TECHNOLOGY

Today we did an experiment to recover iron from steel slag for customers in Turkey. The result of the experiment was very good.

RECOVERING IRON FROM STEEL SLAG, GRADE MORE THAN 95%, EXPERIMENT

Today we did an experiment to recover iron from steel slag for customers in Turkey. The result of the experiment was very good.

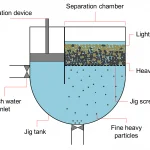

WORKING PRINCIPLE OF JIG MACHINE

Today we sent a shipment to Mexico, which includes jigs, spiral washers, and vacuum filters. The jig can improve the grade of barite.

DISCUSSION ON GRAVITY BENEFICIATION PROCESS AND EQUIPMENT CONFIGURATION OF LEAD-ZINC ORE

Compared with the flotation, gravity beneficiation of lead-zinc ore has many advantages, such as small investment, low cost, and no pollution.

DO YOU KNOW HOW I GOT 6 OUNCES OF GOLD FROM A GOLD MINE IN ONE DAY?

If you have a gold mine with a gold content of about 2g/m³, then you can get 6 ounces of gold in one day. It’s about 10498.8 US dollars.

Do You Know How to Extract Gold Based on the Nature of Gold Mines?

Factors that affect the efficiency of gold extraction include the gold mine nature, the beneficiation equipment, and the method of operation.

HOW FOUR ROLL CRUSHERS WORK

Four Roll Crushers are used in scenarios with high productivity, large feed size, and high crushing ratio.

MANGANESE ORE BENEFICIATION TECHNOLOGY

Commonly used manganese ore beneficiation methods are mechanical beneficiation, including ore washing, screening, gravity separation, etc.

PRINCIPLES OF JIGGING BENEFICIATION: A VIEW OF POTENTIAL ENERGY STRATIFICATION

Stratification is the process of reducing the internal potential energy of the mineral jig bed by redistributing the material in the bed.

HOW TO USE MERCURY TO EXTRACT GOLD FROM GOLD ORE

Because gold can be swallowed by mercury to form amalgams, we can use mercury to extract gold from gold mines.

INTRODUCE SEVERAL TYPICAL TANTALUM-NIOBIUM ORE BENEFICIATION PLANTS

The tantalum-niobium beneficiation process includes crushing, screening, and gravity beneficiation to obtain mixed coarse concentrate.

DO YOU KNOW WHAT THE STEEL SLAG PROCESSING PRODUCTION LINE IS LIKE

The steel slag processing production line’s main function is to extract steel grains and iron blocks from steel slag.

DO YOU KNOW WHAT EQUIPMENT TO USE TO EXTRACT USEFUL MINERALS FROM ORE?

Jig concentrator is suitable for the beneficiation of non-metals, ferrous metals, non-ferrous metals, smelting slag, and other materials.

THE TANTALUM-NIOBIUM ORE BENEFICIATION PROCESS YOU WANT TO KNOW

Usually, the beneficiation process of tantalum-niobium ore consists of two parts: roughing and beneficiation.

HOW DOES TROMMEL SCRUBBER WASH ORE?

Trommel scrubber is generally used for large ore that is difficult to wash. It can effectively improve the mineral grade.

HEMATITE BENEFICIATION PROCESS, HOW TO IMPROVE THE GRADE OF HEMATITE

The main beneficiation methods include gravity beneficiation, flotation, weak magnetic method, and the roasting beneficiation method.