Mineral processing equipment is indispensable in ore processing. These equipments include crushers, screening machines, gravity separation equipment, flotation machines, magnetic separators, dewatering machines, and conveyors. The efficient operation of these machines is crucial for the smooth progress of the mineral processing plant, encompassing key processes such as ore crushing, mineral separation, and material transportation.

The efficient operation and maintenance of mineral processing equipment can significantly enhance a company’s production capacity, reduce downtime of mining machines, and maintenance costs, thus enhancing the overall economic efficiency of the mineral processing plant. Preventive maintenance and timely repairs can extend the service life of the equipment, reduce unexpected failures, and ensure the continuity and stability of the processing line. This article explores strategies to maximize equipment uptime while minimizing costs.

- Basic Principles of Maintenance in Mineral Processing Plants

- Common Problems and Solutions in Mineral Processing Equipment

- Measures to Improve the Operation Life of Mining Equipment

1.Basic Principles of Maintenance in Mineral Processing Plants

To maintain the normal operation of mineral processing equipment and reduce downtime, preventive maintenance and timely repairs are necessary

1.1 Preventive Maintenance

Preventive maintenance involves regular inspections and maintenance to prevent unexpected failures and ensure the efficient operation of mining machines.

Content of preventive maintenance:

- Understanding equipment performance: Equipment maintenance personnel need to fully understand the performance of the mineral processing equipment, including the replacement time of vulnerable parts and the identification of signs of equipment failures. For example, monitoring the vibration and sound of a ball mill can help detect potential mechanical issues and carry out repairs promptly.

- Developing inspection plans: Establish a strict inspection system for equipment, perform comprehensive inspections at specific times and locations, including the lubrication system and the tightness of bolts. Maintenance plans should include regular inspection schedules and measures for common failures to solve problems quickly when they arise.

- Regular inspection schedule: Each type of equipment has its optimal inspection period. Rationally arranging inspection times can minimize downtime and ensure the efficient operation of the processing line.

- Pre-emptive measures: This includes replacing worn parts, cleaning hydraulic systems, and repairing electrical components, to ensure quick production resumption when failures occur. For example, regularly replacing the grinding balls in a ball mill can maintain crushing efficiency, reduce electricity consumption, and ultimately lower production costs.

1.2 Timely Repairs

Timely repairs refer to the rapid response and repair of equipment when failures occur, and include:

- Quick response: Promptly arrive at the site to conduct an initial inspection and fault diagnosis.

- Fault repair: Prepare repair tools and spare parts to replace or repair damaged components urgently.

- Functional testing: Ensure that the equipment has resumed normal operation.

- Maintenance records: Detailed records of the repair process should be kept to provide data support for subsequent preventive maintenance.

By implementing these principles, downtime of mineral processing equipment can be minimized, production efficiency can be improved, and maintenance costs can be reduced.

2. Common Problems and Solutions in Mineral Processing Equipment

2.1 Wear or Blockage

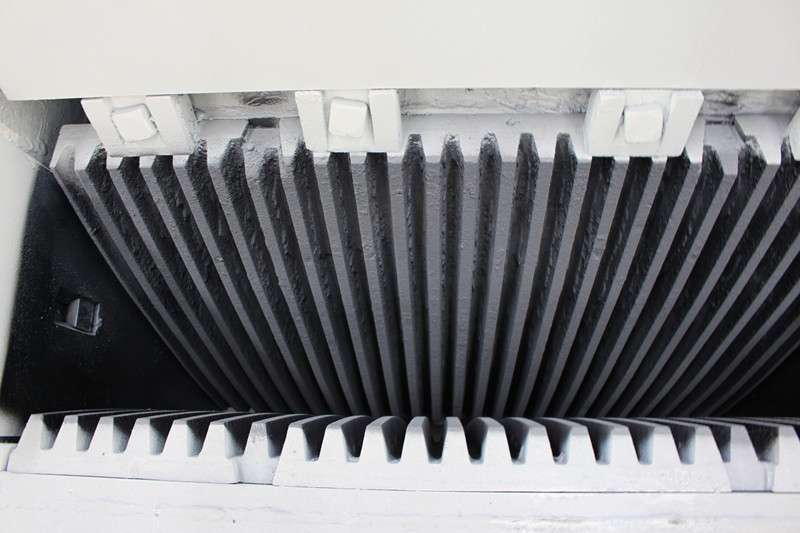

In mineral processing plant, crushing and grinding equipment, such as the jaw plate, impact plates, and liners of crushers, are prone to wear during long-term use. Excessive wear of jaws and hammers can lead to a decrease in crushing efficiency.

Blockages in screening equipment can cause material discharge difficulties. And damage to transmission components such as bearings and gears can cause machine downtime. In addition to normal wear and tear, harsh working environments, improper operation, and lack of lubrication can all contribute to additional wear on equipment.

2.2 Hydraulic System Failures

Due to their greater kinetic energy and easier operation, hydraulic systems are widely used in large-scale mineral processing equipment, such as hydraulic crushers, hydraulic jigs, and hydraulic thickeners.

Causes of failure: Hydraulic oil contamination is a common cause of hydraulic system failures. Contaminants can clog hydraulic pipes and accelerate component wear. Therefore, it is necessary to regularly replace hydraulic oil and filters to ensure a clean internal system.

2.3 Electrical System Failures

In modern manufacturing, electrical systems are widely used to regulate mining equipment operating conditions and improve mineral processing efficiency. Electrical system failures are often manifested in control component failures, short circuits, and other issues.

3.Measures to Improve the Operation Life of Mining Equipment

3.1 Use of qualified lubricants

For critical mechanical components in processing equipment such as gears and bearings, regular lubrication is necessary. Selecting qualified, clean lubricants and hydraulic oils, and ensuring adequate and uniform lubrication can reduce friction, wear, and significantly extend the life of machine components.

3.2 Regular equipment inspection and maintenance

It involves cleaning the equipment to remove dust and debris, checking for damage like cracks and wear, and ensuring proper equipment function. Caring the operating environment to reduce equipment failures. For example, taking appropriate measures to prevent overheating in summer and freezing in winter.

3.3 Equipment spare parts management

Stock essential components like ball mill steel balls and crusher wear parts for swift replacements. Balance inventory to avoid overstocking based on historical data and forecasting. This optimizes costs and minimizes downtime.

3.4 Optimizing the mineral processing process

In a budget-constrained environment, simplifying the process is crucial to reducing downtime. Evaluate the mineral processing process and identify redundant steps that can be eliminated or optimized. Implementing lean principles can help maximize efficiency and minimize waste.

3.5 Operator training

Training operators to strictly follow operating procedures is essential to ensure the safe operation of mining equipment. Cross-train staff for flexibility, maintaining productivity even with absences.

3.6 Personnel safety

In production, safety always comes first. Ensure that all safety protocols are strictly followed and that employees are equipped with the necessary personal protective equipment. Safety incidents not only prolong downtime but also jeopardize lives.

Maintenance of mineral processing equipment is crucial to the efficiency of mining operations. Forui Machinery has dedicated 30 years to the research and development of beneficiation equipment. Our equipment has been widely applied in numerous mines worldwide, earning recognition from our clients. We not only offer customized beneficiation solutions and high-quality equipment, but also provide a comprehensive after-sales service system, including equipment installation, debugging, and spare parts supply.

Choosing us means selecting a reliable and worry-free partner. If you have questions about mineral processing, contact us.

Forui Machinery

Email: Kathy.niu@foruiming.com

Email: Support@foruimining.com

Whats APP: +8618838083794

* Ore Washer Maintenance: Spiral Washers, Log Washer, Rotary Scrubber