1. Brief introduction of tantalum-niobium mine

Tantalum-niobium ore refers to the general name of minerals containing tantalum and niobium, and there are more than one hundred species. The tantalum-niobium ore that can be used for ore mining mainly consists of tantalite, columbite, and pyrochlore. Tantalite contains more tantalum called tantalite and contains more niobium called columbite. The following picture shows the original tantalum-niobium ore mining site in a country in Africa:

2. Beneficiation technology of tantalum-niobium ore

The beneficiation method of tantalum-niobium ore needs to be determined according to the nature and structure of the ore. Under normal circumstances, we divide tantalum-niobium ore into two types according to the difficulty of beneficiation, one is tantalum-niobium ore with complex structure and composition, and the other is tantalum-niobium ore with single structure and composition. Tantalum-niobium ore in China and tantalum-niobium ore in Africa are just the representatives of these two tantalum-niobium ores.

3 China’s tantalum-niobium ore beneficiation technology

The grade of tantalum-niobium ore in China is generally very low, the ore is relatively brittle, and the density is high. Generally, the process of staged grinding and staged beneficiation is adopted. The tantalum-niobium mine in Yichun, Jiangxi, China adopts the process of staged grinding and staged gravity beneficiation for beneficiation. Finally, a concentrate containing 14.94% tantalum and niobium was obtained, and the recovery rate was 75%.

An ore body in Dajishan, Jiangxi, China is a large granite ore body containing tantalum, niobium, and tungsten. The main minerals include wolframite, scheelite, tantalite, etc. Since the particle size of the useful minerals in this mineral is very fine, if only a single gravity beneficiation method is used, the recovery rate is very low, so it is necessary to increase the flotation process.

The results of the concentrate obtained by the combined gravity beneficiation-flotation process by the Guangzhou Research Institute of Nonferrous Metals in China are as follows:

- Contains 10.84% tungsten trioxide

- Tantalum pentoxide 51.8%

- The recovery rate of raw ore is 69.92% (Ta2O5 recovery rate)

- The selected recovery rate is 94.11%

- The yield of tin concentrate is 0.0581%

- Contains Sn60.25%

- The recovery rate of raw ore is 58.49%

- Recovery rate of selected jobs is 89.84%

For the complex and difficult-to-select tantalum-niobium ore, we generally use a combination of gravity beneficiation, flotation, magnetic separation, and a combination of multiple methods. Before determining the beneficiation process of tantalum-niobium ore, it is necessary to understand the nature and structure of tantalum-niobium ore.

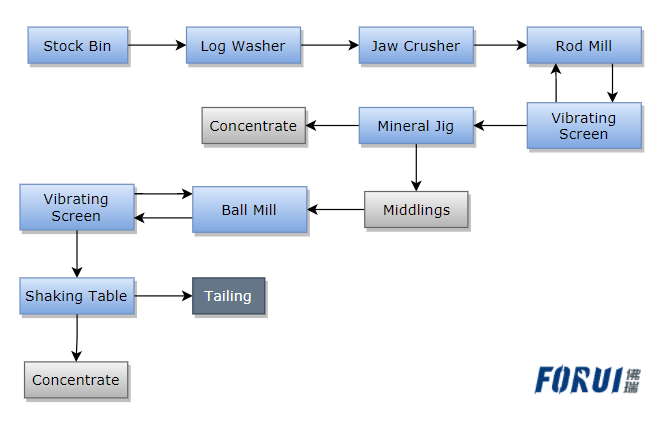

The picture below shows the beneficiation process of a fine-grained embedded tantalum-niobium ore in China Schematic diagram:

Although China’s reserves of tantalum-niobium ore are poor, the beneficiation technology of tantalum-niobium ore is not backward. Regarding the beneficiation of tantalum-niobium ore, Forui Machinery has a lot of practical experience and technology. Welcome to inquire or go to the factory for a beneficiation test. Contact number: +8618026978087.

Gongyi Forui Machinery Factory, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. We can design and manufacture professional tantalum-niobium ore processing equipment for you. Welcome to visit our company. We are dedicated to serving you! If you need equipment quotation and process flow, please feel free to Contact Us:

- Whatsapp: +8618026978087

- Email: asa.guo@foruimining.com