Overview

The gold in placer gold mines is generally single-particle gold, and the monomer dissociation degree is relatively high, most of which are granular, flake, etc. The size of gold is generally 0.5-2mm, so the method of gravity beneficiation-amalgamation can be used. A good beneficiation effect has been achieved. Before gravity beneficiation, the large pieces of waste rock in the alluvial gold ore should be screened out to prevent the stones from blocking the screen of the gravity beneficiation equipment. However, in addition to gold, the placer gold ore also contains other heavy minerals. Gravity beneficiation can be used to remove They recycle together.

Use Gravity Beneficiation Equipment to Extract Gold from Placer Gold Mines

Placer gold mines mostly contain mud lumps. If these mud lumps are not broken up and then discarded with the waste rock during the screening process, the lumps will wrap the gold and cause the loss of gold. We can use a trommel to complete the disintegration and screening operations. The trommel is roller-type screening equipment. Generally, the screen size of 10-20mm is used to screen placer gold.

The screened alluvial gold ore can enter the gravity beneficiation process. The practice has proved that the gravity beneficiation method is the most effective and economical placer gold beneficiation method. It mainly uses the difference in specific gravity between gold and waste sand and uses water as a medium for separation. No need to add chemicals, no pollution to the environment, and a high recovery rate.

Due to the different particle size composition of gold in alluvial gold mines, the effective particle size of the materials processed by various gravity beneficiation equipment is also different, so the reasonable placer gold beneficiation process should be a joint operation of the sluice box, jig machine, shaker, and other equipment, first, use sluice box After rough selection, then sweep selection with jig machine, and shake table selection, the recovery rate of gold can reach more than 95%. The LTA-1010/2 jigging machine and 2LTC-6109/8T jigging machine produced by our factory have been widely used in placer gold beneficiation and have been highly praised by users for many years.

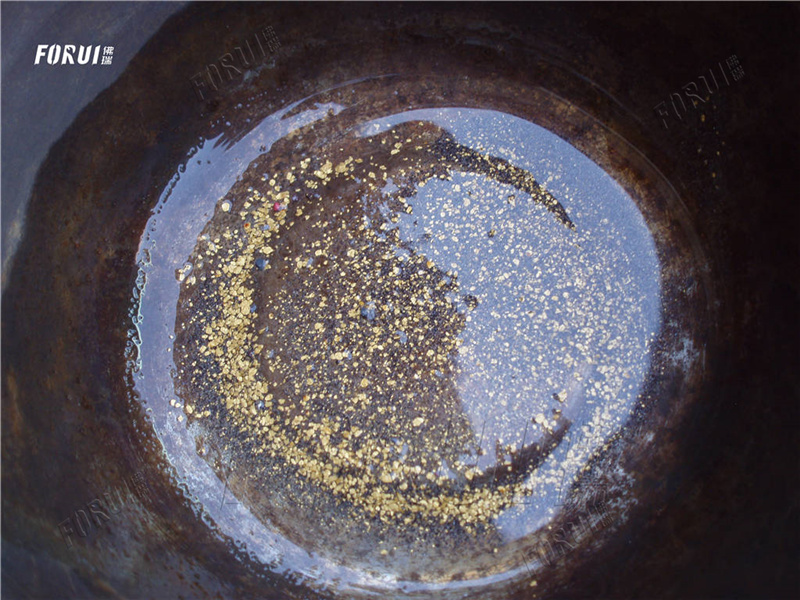

Compared with the raw ore, the gold content of the concentrate obtained by the gravity beneficiation process is relatively high, and then the efficiency of extracting gold by the amalgamation method will be further improved. The amalgamation method for extracting gold is based on the characteristics of gold particles that are easily wetted by mercury, so that mercury can diffuse into the gold particles to form amalgams, thereby capturing gold.

The amalgamation cylinder produced by our factory is specially developed for the heavy sand obtained after the gravity beneficiation of alluvial gold. It is easy to operate and has little environmental pollution. The recovery rate of gold can reach more than 98%, and the mercury used in extracting gold can be recycled and is an efficient equipment for extracting gold.

Gongyi Forui Machinery Factory is a high-quality enterprise specializing in the production of beneficiation equipment. Over the years, it has produced gravity beneficiation, magnetic separation, flotation, and other beneficiation equipment, and has accumulated a lot of practical experience. Forui Machinery is involved in lead-zinc ore, gold ore, fluorite, barite, pyrite, hematite, limonite, magnetite, manganese ore, antimony ore, tungsten ore, tin ore, celestite, etc. In the field of beneficiation of a variety of minerals, fruitful results have been achieved.

If you need equipment quotation and process flow, please feel free to Contact Us