The alluvial gold beneficiation production line is located in Guinea, Africa. Its capacity is 100TPH. The following is the beneficiation process of the ore dressing project.

1. Sample Attributes

Specific Gravity: The average specific gravity is 17.50 ~ 18.0.

Grade: about 0.5g/t.

Size Range: The size range of most gold is 0.25 ~ 2mm.

Other Minerals: contains small amounts of Cu, Pb, Zn, S, Fe, Ag, Sb and W, etc.

2. Gold Beneficiation Production Line Process

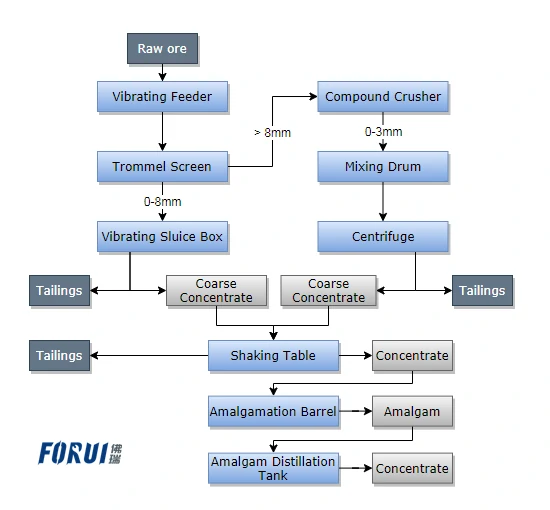

The alluvial gold beneficiation technology mainly includes Preparation and Beneficiation.

2.1 Preparation of Gold Beneficiation Production Line

Overview

The preparation consists mainly of breaking up and sieving. Breaking up is mainly the separation of mineral grains and clayey slime from mined ore. Screening is to screen out coarse grain grades without gold. Commonly used equipments are plane screen, trommel screen, cylinder scrub machine, etc. The concentrator uses the trommel screen to complete the breaking up and sieving operations simultaneously. Greatly improved the work efficiency of gold beneficiation.

Preparation Process

The raw ore is first fed into the hopper. And then into the vibrating feeder after passing through the hopper. The vibrating feeder can ensure that the gold ore is evenly fed into the trommel screen to achieve the best beneficiation index. The role of the trommel screen is to dissociate the slime. And then, the placer gold deposits are divided into two grades, 0-8mm and greater than 8mm.

2.2 Beneficiation of Gold Beneficiation Production Line

Overview

The beneficiation of placer gold is mainly by gravity beneficiation. On the one hand, the placer gold specific gravity is significant (average 17.50 ~ 18.0), and the grain size is relatively coarse (generally 0.25 ~ 2mm). On the other hand, the gravity dressing is more environmentally friendly, economical and easy to operate and maintain. Gravity dressing equipments generally adopts various types of vibrating sluice box, centrifugal concentrator, mineral jig and shaker. The equipments provided by Frei machinery Factory for Guinea gold processing plant is the vibrating sluice, centrifugal concentrator, shaker, amalgamation barrel and amalgam distillation tank, etc.

Beneficiation Process

2.2.1 Mineral Dressing With Sluice Box

Feed 0-8mm alluvial gold ore into the vibrating sluice box to obtain tailings and coarse concentrate.

2.2.2 Mineral Dressing With Centrifugal Concentrator

Send the gold ore ore larger than 8mm through the conveyor to the compound crusher for crushing. After crushing by crusher, 0-3mm alluvial gold deposit was obtained. Then the 0-3mm gold ore is fed into the mixing barrel to form slurry. Then the slurry is fed into the centrifugal separator to get tailings and coarse concentrate.

2.2.3 Mineral Dressing With Shaking Table

Feed the coarse concentrate obtained from the vibrating sluice box and the centrifugal separator to the shaker. After further treatment by the shaking table, you’ll obtained the concentrate.

2.2.4 Mineral Dressing With Amalgamation Barrel

Feed the concentrate into the amalgamation barrel. How it works: Mercury wets gold particles selectively and then diffuses into the wetted gold particles to form the mercury-amalgam compound. Then it is processed by the amalgam distillation tank to obtain the higher grade concentrate.

If you have any comments or suggestions, please feel free to leave a comment below or CONTACT US directly.

Gongyi Forui Machinery Factory, founded in 1986. We are one of the leading suppliers of beneficiation equipments in Asia. Don’t hesitate to Contact Us, if you have any question of beneficiation. And welcome to visit our company. Gongyi Forui Machinery Factory dedicated to serve you!