Overview

The beneficiation principle of placer gold ore is to first use gravity beneficiation to recover gold and its associated heavy minerals to the maximum extent from the original ore. Furthermore, combined operations such as gravity beneficiation, flotation, amalgamation, and magnetic separation are used to separate gold from other heavy minerals, and comprehensively recover the useful minerals.

Placer gold ore beneficiation is generally divided into processes such as crushing and screening, desliming, and beneficiation.

Crushing and screening

Placer gold mines generally contain mud lumps. If the mud lumps with a particle size greater than 100mm are not crushed, they will be discharged with the waste rock during the screening process, causing the loss of gold along with the mud lumps. In addition, the mud mass can also stick to the gravel, and if it is not broken up, it will cause the loss of gold during the screening process. At the same time, crushing and screening operations can eliminate 20% to 40% of waste rock, gravel, and pebbles, which is an indispensable process in placer gold beneficiation.

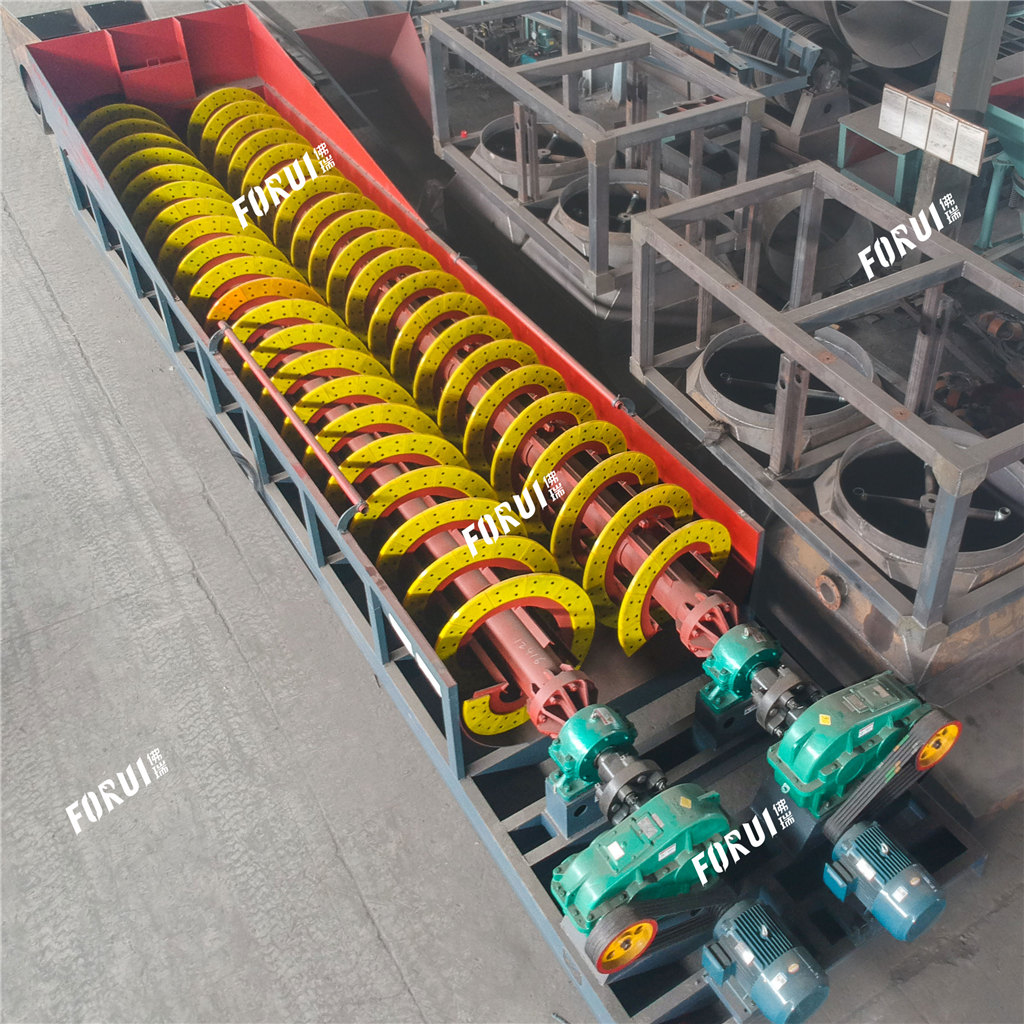

Common washing equipment includes the following: trommel scrubber, log washing machine, spiral washing machine, etc.

For medium washable placer gold, the drum washing machine has a sufficiently high fragmentation and classification effect. For difficult-to-wash placers with high clay content, spiral washers or log washers are often used.

On the gold dredger, the disintegration and screening operations are done together in the trommel. The trommel is equipped with intermittent spiral-angle steel and high-pressure washing water. The screening equipment is divided into grid screens and vibrating screens, and the minerals in them are repeatedly washed. Reasonable screening parameters must be determined according to the particle size of the gold in the placer gold mine. Flushing operation at the same time as screening can not only improve the screening efficiency but also further break down the mud. Therefore, high-pressure water is often used in the screening process of placer gold mines.

Desliming

In placer gold mines, materials generally smaller than 0.1mm do not contain gold or contain very little gold. For example, in the placer gold mines of the Hunchun Gold Mine and the Huanan Gold Mine, gold less than 0.1mm accounted for only 0.15% and 0.18%, respectively, while the sludge of the same size accounted for 13.77% of the placer gold content. In addition, gold smaller than 0.1mm is commonly known as floating gold, and it is also difficult to recover during the beneficiation process, while the sludge of the same size will interfere with the beneficiation process. Therefore, in the placer gold beneficiation plant, the sludge less than 0.1mm needs to be removed. Placer gold mines can be deslimed using spiral washers or log washers.

Beneficiation

Gravity beneficiation is the most economical and effective method for dealing with placer gold ore. However, due to the different particle size composition of gold in placer gold mines and the different effective feed size ranges of various gold recovery equipment, the beneficiation process of placer gold mines is often completed by multiple gravity beneficiation equipment. These pieces of equipment include sluice boxes, jig concentrators, spiral chutes, shakers, centrifuges, etc.

The gold grade of the crude concentrate obtained in the roughing stage is about 100g/t. For this kind of crude concentrate, we can use the following three methods for beneficiation:

- Use a shaker for selection and directly obtain high-purity gold.

- Use an amalgamation cylinder for selection, after obtaining amalgam, use a distillation tank to extract pure gold.

- Use manual panning. This method is very inefficient, and the loss rate of gold is very high. This method is generally not recommended.

Gongyi Forui Machinery Factory is a high-quality enterprise specializing in the production of beneficiation equipment. Over the years, it has produced gravity beneficiation, magnetic separation, flotation, and other beneficiation equipment, and has accumulated a lot of practical experience. Forui Machinery is involved in lead-zinc ore, gold ore, fluorite, barite, pyrite, hematite, limonite, magnetite, manganese ore, antimony ore, tungsten ore, tin ore, celestite, etc. In the field of beneficiation of a variety of minerals, fruitful results have been achieved.

If you need equipment quotation and process flow, please feel free to Contact Us