Lead-zinc ore is a common metal mineral. In the past, the beneficiation of lead-zinc ore was dominated by flotation. As time goes by, there are fewer and fewer rich ore. If adopts froth flotation to process low-grade lead-zinc ore, although qualified concentrate can be produced, there is no economic benefit or even loss.

One thing that must be considered in the beneficiation of low-grade lead-zinc ore is: how to reduce production costs and equipment investment costs.

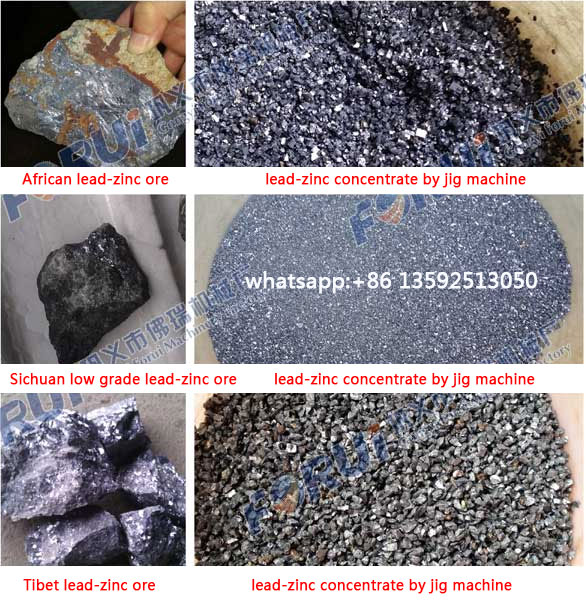

Here we will introduce a beneficiation solution for low-grade lead-zinc ore: pre-concentration by gravity separation, it can effectively discard the gangue in the raw ore, improve the grade by mineral jig machine.

Then send it to the flotation plant or sold directly(for some type of lead zinc ore, the final concentrate can be produced directly by gravity separation).

1.How does the mineral jig machine remove the gangue and impurities in the lead-zinc ore?

The Mineral Jig Machine belongs to a gravity concentrating device that separates material based on differing densities of the material. After feeding the material to the mineral jig machine, Separation takes place as a result of the periodical influence of the upward and downward of water (pulsations). Under the action of pulsations, the bed is alternately loosened and compacted, and the particles of different densities mutually move on its height: gangue with small density – into upper layers, lead-zinc minerals with big density-into bottom layers. The formed layers of different densities are separately removed as a concentrate and wastes.

The following video is the pre-concentration lead-zinc ore by mineral jig machine:

2.Low-grade Lead-zinc Ore Beneficiation Process

The beneficiation process of low-grade lead-zinc ore can be divided into two types: a single gravity separation process and a gravity separation-froth flotation combined process.

For coarse-grained lead-zinc ore, a single gravity separation process can obtain ideal beneficiation results, and the final concentrate product can be directly produced according to customer requirements.

raw ore–coarse crushing–fine crushing–jigging separation–concentrate

The following is a production site video of a single gravity separation process:

For fine-grained lead-zinc ore, the combined process of gravity separation and froth flotation should be adopted.

raw ore–coarse crushing–fine crushing–jigging separation–rough concentrate–grinding–classification–froth flotation–final concentrate

First, a large amount of waste rock is discarded by a jig machine for pre-concentrate, and then a flotation machine is used for final upgrading to obtain the final concentrate.

The following is the production site video of the gravity separation-froth flotation combined process :

3.Equipment Configuration

The beneficiation equipment for low-grade lead-zinc ore includes: jaw crusher, fine crusher, mineral jig machine, ball mill, spiral classifier, flotation machine, etc. Depending on the characteristics of the ore, different beneficiation techniques and beneficiation equipment are required.

Forui Machinery has provided dozens of lead-zinc ore beneficiation production lines for Chinese and overseas customers, we have rich experience in the beneficiation of low-grade lead-zinc ore, we supply free mineral processing, flowchart designing, equipment configuration, complete experiment set of lead zinc ore beneficiation plant, On-site installation and commissioning and staff training, if you want more details, don’t hesitate to contact us.