Introduction

Sulfur slag, also known as pyrite slag or sulfuric acid slag, is a kind of chemical waste residue. In the production of sulfur, the sulfur in the pyrite is extracted and used, and iron and other elements become the slag. Therefore, the sulfur slag can be used as the main resource for ironmaking and extraction of non-ferrous metals. At present, sulfur slag is a typical mine solid waste in China, mainly distributed in Yunnan, Sichuan, Guizhou, Hubei, and Guangdong.

According to the different sintering degrees of sulfur slag, the iron element in it exists in different forms, mostly in the form of iron oxide, and there is also a small amount of ferrous disulfide. In order to recover the iron in the sulfur slag, we must first understand the form and properties of the iron in the sulfur slag, and then determine the beneficiation process and equipment based on these properties.

Types of Sulfate Slag and Beneficiation Process

The content and properties of iron minerals in sulphuric acid slag are mainly controlled by production conditions. During production, the degree of oxidation is changed by adjusting the ratio of air to material, thereby changing the relative composition of iron minerals. Therefore, sulphuric acid slag can be divided into three categories according to production conditions:

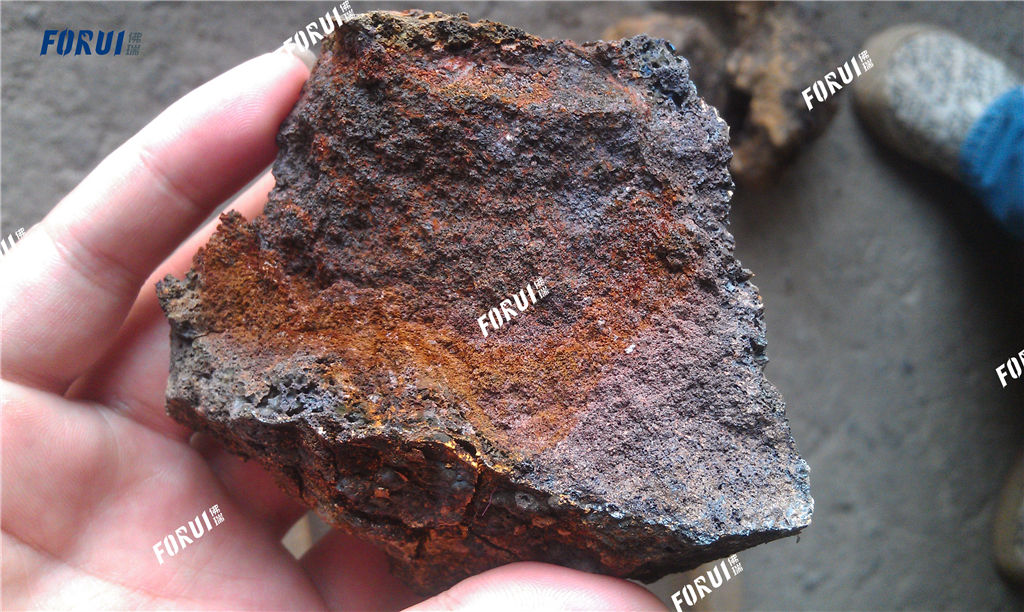

- Peroxidized sulphuric acid slag: It is formed under the condition of a high wind-to-material ratio, and is reddish-brown. The main iron mineral is hematite.

- Normal sulphuric acid slag: It is formed under the condition of moderate wind-to-material ratio and is iron-black, and the content of hematite and magnetite is roughly equal.

- Low-oxygen sulphuric acid slag: It is formed under the condition of a low wind-to-material ratio, and is iron-black. The main iron mineral is magnetite, sometimes containing FeO.

The main iron mineral is hematite sulphate slag. Gravity beneficiation technology is generally used. For iron minerals, hematite and magnetite sulphate slag can adopt gravity separation-magnetic separation combined process. For iron minerals, it is magnetic. The sulphuric acid slag of iron ore directly adopts the magnetic separation process. Under normal circumstances, the recovery rate and concentrate grade of the magnetic separation method is difficult to meet the ideal requirements, but the gravity separation method can obtain the ideal beneficiation index.

The sulphuric acid slag gravity beneficiation production line uses crushing, screening, jigging, and other processes to recover the iron minerals in the sulphuric acid slag, and the final iron content is between 56% and 61%. The sulphuric acid slag gravity beneficiation production line has low equipment investment, low operating cost, and high iron separation efficiency. At present, there are many sulphuric acid slag gravity beneficiation production lines in Hubei and other regions, which have obtained high beneficiation indicators.

Gongyi Forui Machinery Factory is a high-quality enterprise specializing in the production of beneficiation equipment. Over the years, it has produced gravity beneficiation, magnetic separation, flotation, and other beneficiation equipment, and has accumulated a lot of practical experience. Forui Machinery is involved in a lead-zinc ore, gold ore, fluorite, barite, pyrite, hematite, limonite, magnetite, manganese ore, antimony ore, tungsten ore, tin ore, celestite, etc. In the field of beneficiation of a variety of minerals, fruitful results have been achieved.

If you need equipment quotation and process flow, please feel free to Contact Us