Introduction

Silico-manganese slag is silico-manganese alloy smelting slag. Due to the limitation of the smelting process, the silico-manganese slag will contain 1%-10% silico-manganese alloy. Recovering silico-manganese alloy from the silico-manganese alloy smelting slag can not only reduce the waste of resources, but also At the same time, it can produce very considerable economic benefits.

In recent years, many individuals and companies have joined the field of silico-manganese slag processing, hoping to recover the silico-manganese alloy in the silico-manganese slag, so as to create more economic value. So what is the processing process of silicomanganese slag? How can we obtain economic benefits from it? Let’s share the process flow of Forui Machinery’s silicomanganese slag treatment.

Silico-manganese Slag Treatment Process

Silico-manganese alloy smelting slag is a solid waste slag produced during the smelting of silico-manganese alloy, which is divided into dry lumpy slag and water-granulated slag.

1. Dry Bulk Silico-manganese Iron Slag

It is an acidic silico-manganese slag with a high manganese content (over 40%). It can be recycled and reused as an additive in FeSiMn production (the phosphorus content is extremely low, which is an advantage for FeSiMn production).

2. Water-grained Silico-manganese Iron Slag

It’s a poor slag, which has low manganese content (MnO <20 %). about 30% Si is produced by upgrading the standard alloy through the addition of silicon waste from the iron silicon industry, which at the end of the ferroalloy production process, is discarded.

Their recycling methods are roughly the same, the following is the commonly used silico-manganese slag treatment process:

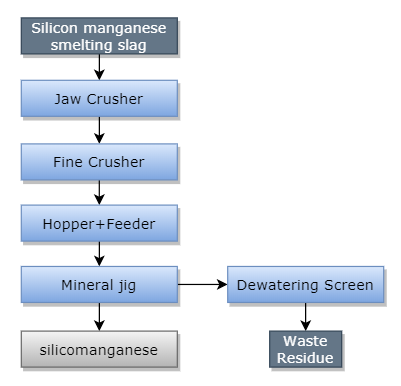

The silico-manganese slag enters the jaw crusher for coarse crushing, and is used to crush large pieces of waste slag. If it is a separate water-granulated slag, there is no need for a jaw crusher, because there are very few large pieces of waste in the water-granulated slag and only need to be finely crushed. The dry lumpy slag contains more large pieces of waste slag, which must be coarsely crushed by a jaw crusher before it can be further finely crushed.

The purpose of crushing is to dissociate the silico-manganese alloy from the silico-manganese slag and avoid the loss of fine-grained alloys in the waste slag due to incomplete crushing. The finely crushed silico-manganese slag enters the silo, and an electromagnetic vibrating feeder is set under the silo to evenly feed the silico-manganese slag into the jig for beneficiation.

Silico-manganese Slag Beneficiation Equipment

The jig machine is one of the most common gravity separation equipment. It uses the difference in specific gravity between the silico-manganese slag and the silico-manganese alloy for separation, and finally a pure silico-manganese alloy can be obtained. The concentrate of the jig machine enters the concentrate pool directly, and the pure silico-manganese alloy can be obtained by digging out after precipitation. The tailings of the jigging machine are dewatered by a dewatering screen and then enter the waste slag field. The waste slag can be sold as raw materials for new building materials.

Summary

The treatment of silico-manganese slag is very simple, and there is only the only way to reselect the jig. Using a jig to recover silico-manganese alloy from silico-manganese alloy smelting slag is a new method of high efficiency, energy saving and environmental protection. At present, this method has been widely used all over the world, and the effect is remarkable, and it has been unanimously recognized by customers.

On-site video of silicomanganese slag treatment:

Silicomanganese Slag Processing Plant in Iran

Gongyi Forui Machinery Factory is a high-quality enterprise specializing in the production of beneficiation equipment. Over the years, it has produced gravity beneficiation, magnetic separation, flotation, and other beneficiation equipment, and has accumulated a lot of practical experience. Forui Machinery is involved in a lead-zinc ore, gold ore, fluorite, barite, pyrite, hematite, limonite, magnetite, manganese ore, antimony ore, tungsten ore, tin ore, celestite, etc. In the field of beneficiation of a variety of minerals, fruitful results have been achieved.

If you need equipment quotation and process flow, please feel free to Contact Us