Overview

Diamond Roughing Equipment

We usually use trapezoidal jigs (side-moving diaphragm jigs) as diamond beneficiation equipment. It is gravity beneficiation equipment. Trapezoidal jigs use water as the beneficiation medium and perform beneficiation based on the difference in the proportion of minerals and gangue. It has four independent beneficiation troughs, each trough can be adjusted independently, the jigging surface is trapezoidal, it has a high recovery rate and processing capacity.

It is widely used in hematite, limonite, placer gold, manganese, tungsten, tin, tantalum, mercury, fluorite, barite, celestite, and other metals and non-metals. Mineral beneficiation. Trapezoidal jigs can also be used to process metal smelting slag and to recover alloy particles and recyclable materials in metal smelting slag.

The trapezoid jig machine consists of eight jigging chambers, divided into two rows, each with four chambers. Its width gradually widens from the feeding end to the discharging end, and the whole machine is trapezoidal when viewed from top to bottom. The machine has a large processing capacity and strong adaptability. It is suitable for the beneficiation of medium and fine-grained ores, and the effective recovery limit is 53 microns. Trapezoidal jigs have been widely used in gravity concentrators for iron ore, manganese ore, tin ore, etc. at home and abroad.

Diamond Beneficiation Equipment

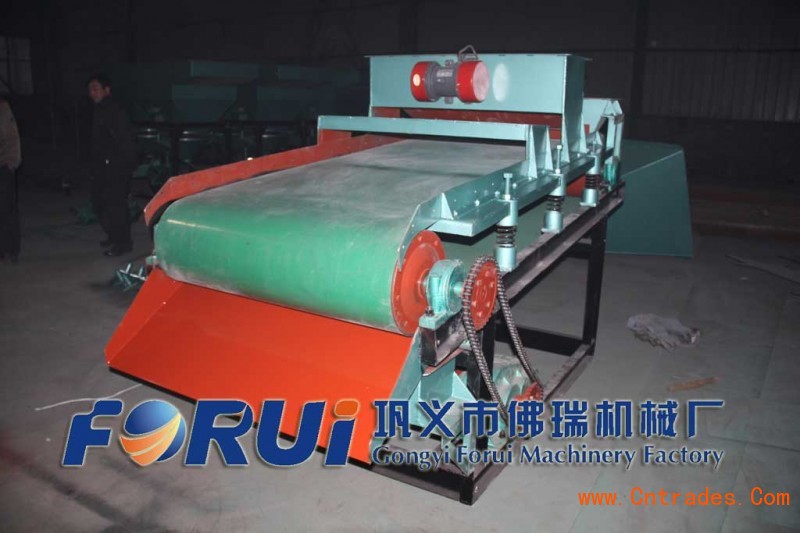

The beneficiation working surface of the vibrating belt type grease concentrator is a sorting belt, which is a conveyor belt around the first wheel and the tail wheel. It has a certain angle with the horizontal, and the angle can be adjusted according to the feed size. The first wheel and the tail wheel are installed on the frame, and the material is fed to the sorting belt by the vibrating feeder, and there is a flushing water pipe on the belt. The oiling tank is installed at the tail wheel end of the tape so that the heated grease in the tank is continuously coated on the sorting tape along with the movement of the sorting tape. An electric scraper is installed at the first round of the sorting tape to continuously scrape off a certain thickness of grease with mineral particles. After deoiling the grease-containing mineral particles, the concentrate can be obtained. After the concentrate is dried, the diamond can be obtained by hand selection. The gangue that cannot stick to the surface of the grease is washed into the tailing tank by the washing water.

The improved vibrating grease concentrator is equipped with a vibrating device under the sorting tape to make the sorting tape vibrate in the vertical direction, increase the number of times the mineral particles contact the surface of the grease and improve the recovery rate of the beneficiation. The vibrating grease concentrator has a processing capacity of 3 times larger than that of the non-vibrating grease concentrator.

Gongyi Forui Machinery Factory is a professional manufacturer of beneficiation equipment. Our factory has designed diamond beneficiation technology and equipment configuration for multiple diamond beneficiation plants and has a complete test platform. It can conduct beneficiation tests and design processes for customers free of charge.

If you need equipment quotation and process flow, please feel free to Contact Us