Overview

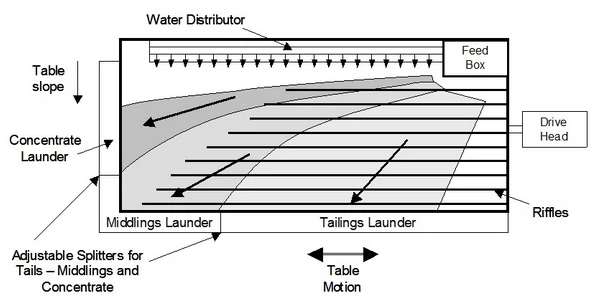

Shaking table is a combination of mechanical asymmetric reciprocating motion and thin inclined surface water flow on an inclined bed surface to loosen, layer, and zone mineral particles on the bed surface, so that the minerals are separated according to different densities.

The shaker has an inclined bed surface, and there are many parallel riffle bars or grooves nailed on the bed surface along the longitudinal direction. One end of the shaker is equipped with a transmission mechanism, which drives the bed surface to make asymmetrical reciprocating motion in the longitudinal direction. The bed surface is inclined to the tailings side by 1.5°~5° transversely, and the slurry and washing water are added from the side with the higher slope of the bed surface.

The ore particles are affected by the longitudinally shaking bed surface and the lateral water flow on the bed surface, so that the ore particles are stratified according to density and size and move along the bed surface in different directions, showing regular “fan-shaped” zoning, and separate from the bed. Different areas on the concentrate end and tailings side of the surface are discharged out of the bed. By receiving them separately, they are divided into concentrate, medium ore and tailings.

The working principle of extracting gold by shaking table

(1) The stratification of ore particles of different densities between the beds

Grooves play an important role in the sorting of the shaker table.

As can be seen from the above figure, the ore particles are distributed in multiple layers in the grooves between the beds: the uppermost layer is coarse and light ore particles, followed by fine and light ore particles, and again are coarse and heavy ore particles, and the bottom layer It is the fine and heavy mineral grains. On the one hand, this stratification is the result of separation due to the dynamic action of the inclined surface water flow and the reciprocating rocking action of the bed surface.

Segregation and stratification is an important feature of shaker sorting. On the other hand, when the water flows through the grooves between the bed bars, eddy currents are formed, causing the pulsation of the water flow, making the ore particles loose and stratifying according to the settling speed. In addition, the eddy current is also advantageous for washing out the low-density mineral particles in the high-density mineral layer. Therefore, the hydraulic grading of the ore feed of the shaking table in advance according to the constant drop ratio is beneficial to the ore dressing. In short, the stratification of ore particles between the beds is mainly due to the combined result of sedimentation stratification and segregation stratification.

(2) Movement and zoning of mineral particles of different densities on the bed surface

While the ore particles are stratified between the beds, they also move in different directions along the bed. In the beginning, the mineral particles are relatively static on the bed surface. To make the mineral particles move relative to the bed surface, only when the inertial force of the mineral particles is greater than the friction force between the mineral particles and the bed surface.

The minimum inertial acceleration necessary for the mineral particles to move from relatively static to rigid energy becomes the critical acceleration. The critical acceleration depends not only on the friction coefficient, but also on the density of the ore particles. It can be seen that the relative movement of mineral particles of different densities on the bed surface is different from the beginning, and the speed is also different.

Summary

From the above, it can be seen that the shaking table ore beneficiation acts on ore particles with different densities under the combined action of inertial force, friction force, segregation, and the impulse of lateral water flow. On the one hand, the speed of the longitudinal movement is different, and on the other hand, the washing effect of the lateral water flow is also different. The final result is a fan-shaped distribution, so as to realize the process of beneficiation.

Gongyi Forui Machinery Factory is a high-quality enterprise specializing in the production of beneficiation equipment. Over the years, it has produced gravity beneficiation, magnetic separation, flotation, and other beneficiation equipment, and has accumulated a lot of practical experience. Forui Machinery is involved in lead-zinc ore, gold ore, fluorite, barite, pyrite, hematite, limonite, magnetite, manganese ore, antimony ore, tungsten ore, tin ore, celestite, etc. In the field of beneficiation of a variety of minerals, fruitful results have been achieved.

If you need equipment quotation and process flow, please feel free to Contact Us