Overview

Limonite is a kind of weakly magnetic iron ore. Its beneficiation methods are mainly gravity beneficiation and strong magnetic separation. There are also cases of using magnetic roasting to treat limonite. However, due to the huge investment in equipment, the cost of beneficiation is excessive. It is not widely used for higher reasons.

The beneficiation and purification methods of limonite need to be determined according to the specific properties of limonite. Limonite is mostly coarse-grained, and there is a clear boundary between iron minerals and gangues. The monomer dissociation of iron minerals and gangues can be achieved by crushing and screening, and then the separation of iron minerals and gangues can be achieved by gravity separation. The method can effectively sort out qualified iron ore concentrates.

Limonite Beneficiation Process and Equipment

The equipment used to beneficiate limonite using gravity beneficiation is mainly a jig. The jigging machine can beneficiate according to the specific gravity difference between limonite and waste rock, and finally obtain limonite with a larger specific gravity and waste rock with a smaller specific gravity, so as to realize the separation of limonite and waste rock and improve iron ore The role of taste.

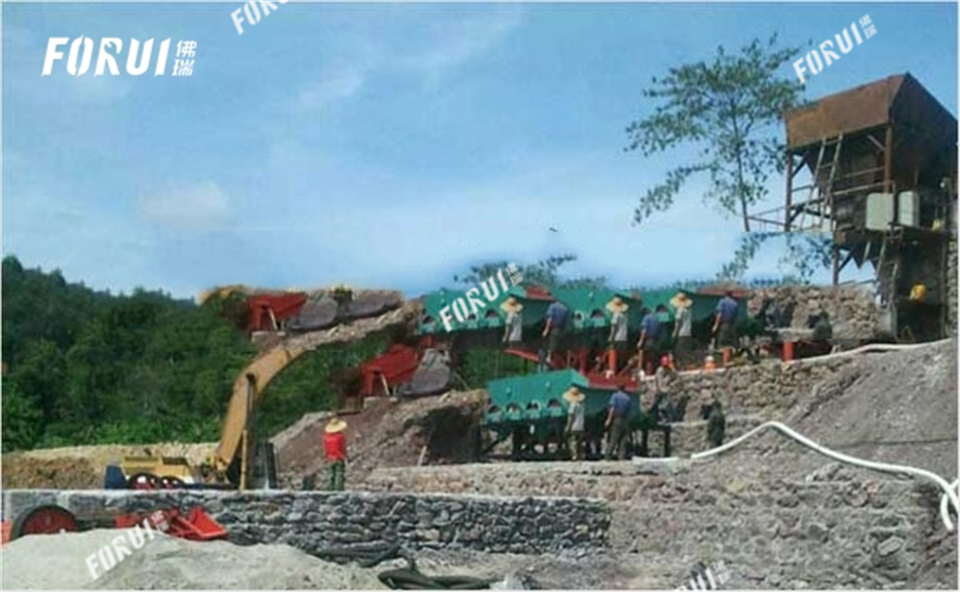

However, only one jig machine cannot complete the limonite beneficiation task, and auxiliary equipment such as crushers, vibrating screens, and feeders are also required. Together, they form a limonite gravity beneficiation production line to perfectly complete the task of limonite beneficiation.

Limonite Gravity Beneficiation

Under normal circumstances, the limonite beneficiation production line must include a crushing process, a screening process, a gravity beneficiation process, a dehydration process, etc. The crushing process adopts jaw crusher, cone crusher and other crushing equipment according to the situation. The screening process adopts circular vibrating screen, linear screen and other equipment. In the gravity beneficiation process, large-particle jigs, fine-grain jigs and other equipment are selected according to the nature of the ore. The dewatering process is to place linear dewatering screens and other equipment after the gravity beneficiation process of the jig to dehydrate the concentrate and tailings for transportation and storage.

Fory Machinery Factory has designed limonite gravity beneficiation technology and equipment for limonite ore dressing plants in many regions of Malaysia, and provided a complete set of system solutions, which has won the trust of Malaysian customers. Malaysia is rich in resources, its iron ore grade is high, the size of the cloth is large, and it has a high degree of selectivity.

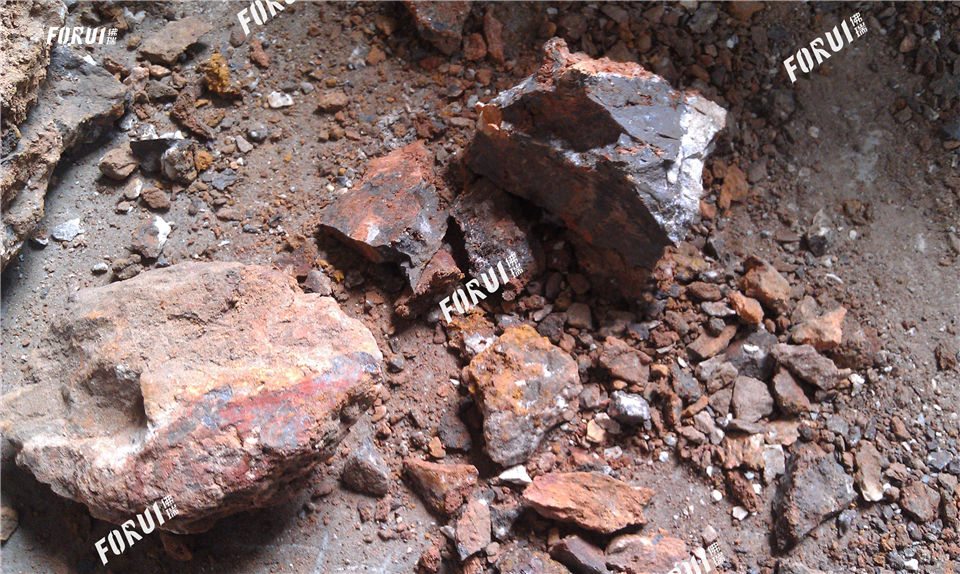

The picture below is a picture of limonite ore in Malaysia. The top is the raw ore. After sieving and washing, the particles are uniform and the color is ocher. The lower left picture shows the concentrate picture of the jig machine, and the lower right picture shows the tailings picture of the jig machine.

The raw limonite ore has a relatively large particle size. After crushing and screening, limonite ore of less than 8mm is obtained for the jig beneficiation test. In fact, the limonite has achieved a high degree of monomer dissociation when the crushing particle size is about 30mm, and it is completely possible to use the large-particle jigger of Frey Machinery for beneficiation. However, our test equipment does not have the ability to process large-particle ore like the large-particle jigging machine, so we can only carry out the optional test of fine-grained minerals for it to prove that the jigging machine has the ability to beneficiate the limonite ore.

Limonite Strong Magnetic Separation

In some water-deficient areas, in the beneficiation of limonite, although the gravity beneficiation method has obvious advantages, it requires a lot of water and cannot be used in dry and water-deficient areas. For such arid and water-deficient areas, the strong magnetic method has become the only option. Dry-type strong magnetic separation does not require water, but there are clear requirements for the particle size of minerals selected, and the beneficiation effect of ore materials with a particle size greater than 5mm is poor.

Therefore, which method and equipment are used for the beneficiation of limonite still needs a detailed analysis of the specific properties of the ore, because not all limonite uses the same method. In order to achieve the best beneficiation effect, please bring 20 kg of limonite samples to Forui Machinery for the beneficiation test of limonite. Gongyi Forui Machinery Factory provides free limonite strong magnetic separation test and gravity beneficiation test.

If you need equipment quotation and process flow, please feel free to Contact Us:

- Whatsapp: +8618026978087

- Email: asa.guo@foruimining.com