Overview

Magnetite is a strongly magnetic mineral, so a beneficiation process based on weak magnetic separation is generally used in magnetite beneficiation. According to the nature of iron ore and the characteristics of the beneficiation process, it can be divided into the following processes.

Single Weak Magnetic Separation Process

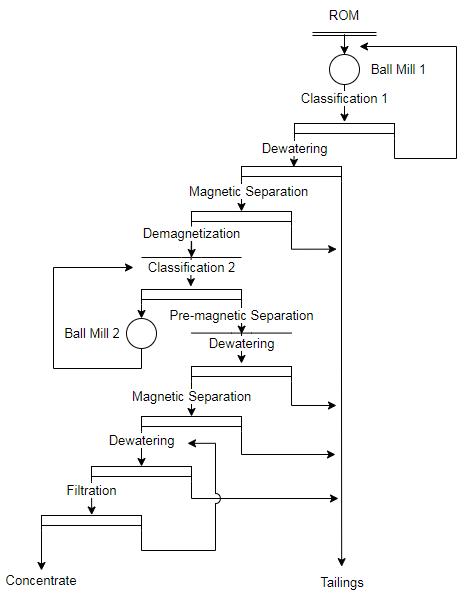

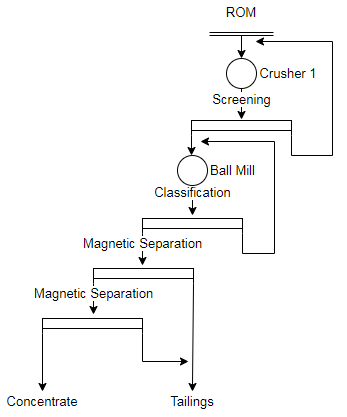

The feature of this process is that the beneficiation process adopts a single weak magnetic separation process, which is suitable for magnetite with simple mineral composition. According to the different process structures, the process can be divided into two types: “continuous grinding-weak magnetic separation process” and “stage grinding-stage beneficiation process”.

‘Weak Magnetic Separation – Reverse Flotation Process‘ and ‘Weak Magnetic Separation – Cleaning Process‘

In recent years, in view of the difficulty of improving the grade of some iron ore concentrates and the high content of impurities such as SiO2 in iron concentrates, China has developed a weak magnetic separation-reverse flotation process, including a magnetic separation-cation reverse flotation process. And magnetic separation-anion reverse flotation process.

The weak magnetic separation-selection process is also mainly aimed at the problem of the difficulty of improving the grade of some iron ore concentrates and the high content of impurities such as SiO2 in the iron ore concentrates. Its characteristic is that the iron concentrate after conventional magnetic separation is selected by special beneficiation equipment to further improve the iron ore grade.

Weak Magnetic – Strong Magnetic – Flotation Combined Process

The combined flotation process is mainly used to process polymetallic symbiotic iron ore and mixed iron ore. According to the different properties of the ore and the characteristics of the process structure, it can be divided into: weak magnetic separation-flotation, weak magnetic separation-strong magnetic separation, weak magnetic separation-strong magnetic separation-flotation.

Pre-selection of Magnetite

With the increase in the amount of lean ore mining, the use of off-surface ore and the need to strengthen mining and increase the mining recovery rate, the problem of ore dilution caused by the mixed rock and waste rock in the ore has become increasingly prominent. In order to reduce capital investment in the concentrator, reduce production costs, and save energy, pre-selection is widely used before magnetite enters the mill. According to the pre-selection method, it can be divided into dry pre-selection of bulk ore, dry pre-selection of powdery ore, and wet pre-selection of powdery ore.

Gongyi Forui Machinery Factory is a high-quality enterprise specializing in the production of beneficiation equipment. Over the years, it has produced gravity beneficiation, magnetic separation, flotation, and other beneficiation equipment, and has accumulated a lot of practical experience. Forui Machinery is involved in lead-zinc ore, gold ore, fluorite, barite, pyrite, hematite, limonite, magnetite, manganese ore, antimony ore, tungsten ore, tin ore, celestite, etc. In the field of beneficiation of a variety of minerals, fruitful results have been achieved.

If you need equipment quotation and process flow, please feel free to Contact Us