Introduction

The beneficiation method of placer tin (cassiterite) is similar to that of placer gold. Generally, the gravity separation method and equipment are used. For placer tin (cassiterite) with a high monomer dissociation degree, good beneficiation results can be obtained by screening-jigging-dehydration.

For the beneficiation of placer tin (cassiterite) with a low monomer dissociation degree, it is necessary to break the conjoined body by rod milling to release tin minerals to improve the beneficiation recovery rate and concentrate grade. The process is: screening-> jigging-> grinding with rod mill-> jigging-> dehydration.

Here is an introduction to the gravity separation method and equipment of the placer tin (cassiterite) for reference!

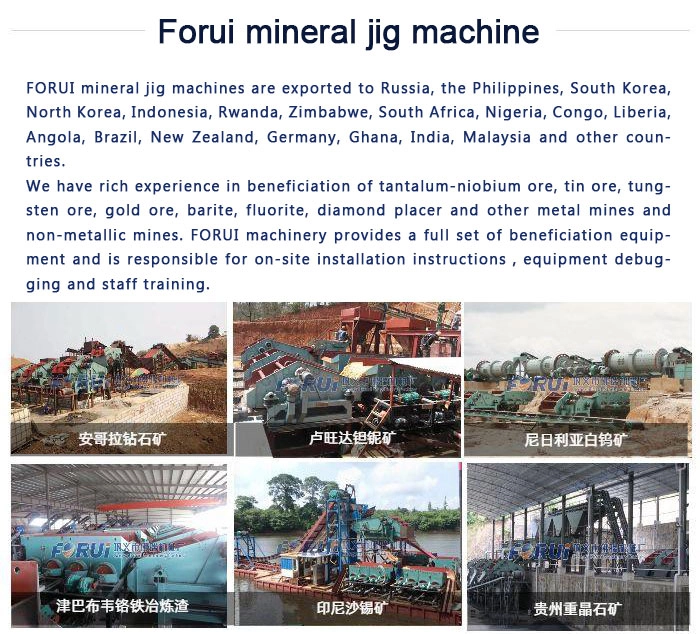

Here are some of our placer tin processing projects:

Projects & Equipments of Alluvial Tin Processing

1. Screening & Washing Equipment

The raw material of the placer tin (cassiterite) is often mixed with large stones such as waste rock and pebbles. These stones are completely free of tin minerals, which will affect the next stage of jigging separation work.

Therefore, the first step in the beneficiation of placer tin (cassiterite) is to screen out these useless stones. The commonly used screening equipment is a trommel screen.

For those placer tin (cassiterite) with large mud content, in addition to screening, it is necessary to wash the ore, break the mud mass, reduce the incidence of tin mineral particles being wrapped in mud, and thereby fundamentally increase tin minerals recovery rate.

2. Gravity Separation Equipment

The basis of the gravity separation of the placer tin (cassiterite) is also the principle of gravity separation: the separation is carried out according to the specific gravity difference between the mineral and the barren material. Since the specific gravity difference between tin and barren material in the placer tin (cassiterite) is very large, the great beneficiation result can be obtained by the method of gravity separation.

The main equipment for placer tin (cassiterite) gravity separation is a mineral jig machine, which has the advantages of large processing capacity and high recovery rate. Sometimes to improve the recovery rate of very fine-grained tin particles, a shaker table is also used.

Commonly used placer tin (cassiterite) gravity separation mineral jig machines are mainly trapezoidal jig machines and downward-moving jig machines.

For placer tin (cassiterite) with a high degree of monomer dissociation, the final concentrate can be obtained by mineral jig at one time.

Feature of Gravity Separation Method

The gravity separation method has the advantages of energy-saving, environmentally friendly, small equipment investment, and low operating costs. It is currently the most ideal, economical, and effective method for placer tin beneficiation.