Introduction

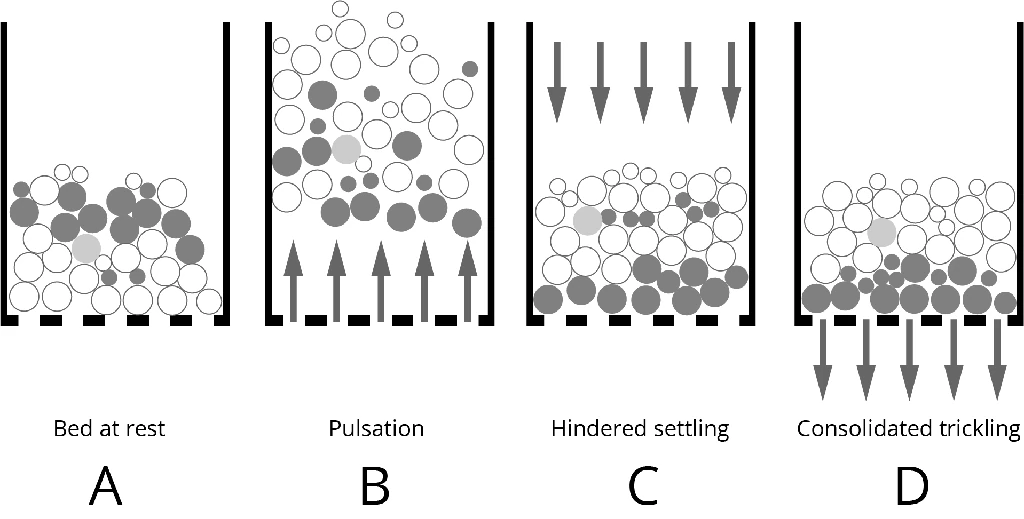

This view was put forward by Mayer (Mayer, 1947), and it is a representative theory among the various theories that analyze the mechanism of the jigging stratification process from the perspective of clusters.

Potential Energy Stratification View

From the various physical and chemical changes in nature, the second law of thermodynamics holds that: any system tends to decrease free energy. In other words, if a process is accompanied by a decrease in energy before and after the change, then this process must proceed spontaneously.

Meyer: Regarding the bed as a whole, it is proposed that the potential energy of the bed before stratification is higher than the potential energy after stratification. Therefore, as long as an appropriate loose condition is created for the bed, heavy materials will inevitably enter the lower layer of the bed spontaneously.

Stratification is the process of reducing the internal potential energy of the bed by redistributing particles of different properties in the bed. The speed at which the bed level can be reduced is the layering speed of the bed.

Mathematical Representation of Potential Energy stratification

In the stratification of the suspension, the lower layer is concentrated with coarse and heavy particles, and the upper layer is concentrated with coarse and fine particles. The main part of the potential energy is transformed into work to overcome various resistances between the particles.

A certain system is uniformly mixed at the beginning, its center of gravity is at H / 2, and its potential energy E1 is:

E1 = ( h1 + h2 ) ( m1 + m2 ) / 2

Where

h1, h2──respectively the thickness of light and heavy materials.

m1, m2──respectively the weight of light and heavy materials.

After a long enough jigging time, it is assumed that the bed layer is completely stratified, that is, all the heavy products are in the lower layer and all the light products are in the upper layer. At this time, the bed position can be reduced to

E2 = h2 m2 / 2 + ( h2 + h1 / 2 ) m1

The energy change before and after stratification is

∆E = E1 – E2 = ( m2h1 – m1h2 ) / 2

= h1h2A ( δ2λ2 – λ1δ1 ) / 2

Since the respective quantities of light and heavy materials in the bed do not change during the stratification process, hlhh/2 and A in the formula are fixed values, and when the stratification process can occur, ∆E must be a positive value. So there is

δ2 λ2 > λ1 δ1

Bulk density is at the bottom. The bulk density of the particle group is the product of the density of the material and the solid volume concentration when the particle group is in the natural accumulation state, and the volume concentration is a function of the shape of the ore particles and the particle size composition of the particle group.

Two kinds of ore particles with the same size but different densities have the same volume concentration when they are naturally stacked. The result of stratification must be that high-density mineral particles are located in the lower layer and low-density mineral particles are located in the upper layer. If two kinds of ore particles with the same density but different particle sizes are naturally stacked, the solid volume concentration of the larger particle size is higher, and the result of stratification must be that the larger particle size is located in the lower layer, and the smaller particle size is located in the upper layer.

Gongyi Forui Machinery Factory is a high-quality enterprise specializing in the production of beneficiation equipment. Over the years, it has produced gravity beneficiation, magnetic separation, flotation, and other beneficiation equipment, and has accumulated a lot of practical experience. Forui Machinery is involved in lead-zinc ore, gold ore, fluorite, barite, pyrite, hematite, limonite, magnetite, manganese ore, antimony ore, tungsten ore, tin ore, celestite, etc. In the field of beneficiation of a variety of minerals, fruitful results have been achieved.

If you need equipment quotation and process flow, please feel free to Contact Us