Overview

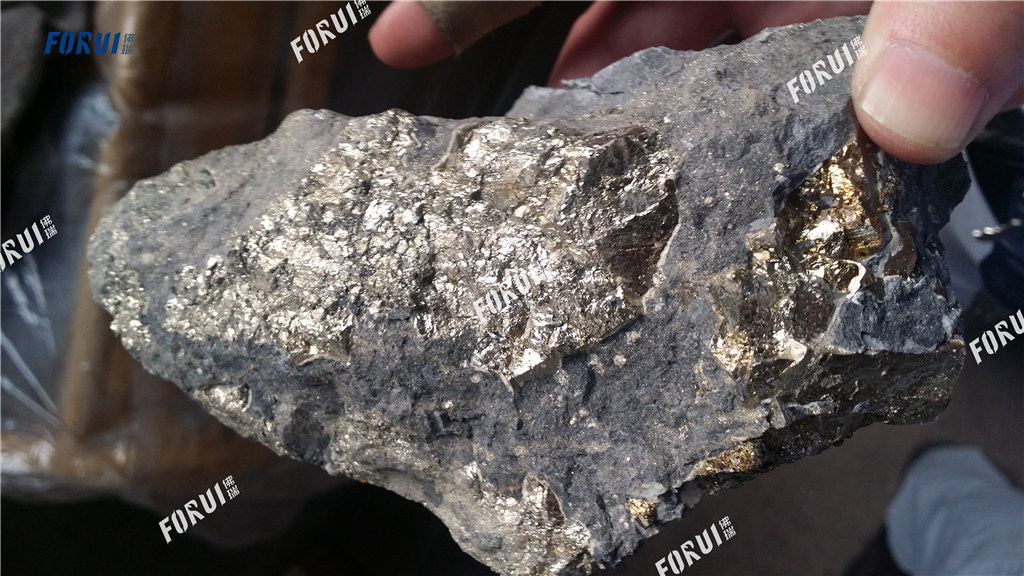

Pyrite, the main component is FeS2. Pyrite is a very important mineral resource. It is the main raw material for extracting sulfur and producing sulfuric acid. It has very important applications in chemical industry, military industry, and agriculture. In addition to individual pyrites and associated pyrites, the sulfur resources in coal measures also mainly exist in the form of pyrites. These three parts of pyrite resources alone account for 83.4% of China’s sulfur resources.

In recent years, the market demand for pyrite has steadily increased, and many countries and regions have produced a shortage of pyrite, which has triggered an upsurge in pyrite beneficiation. However, there are not many manufacturers who really understand and are proficient in pyrite beneficiation. Many manufacturers configure many unnecessary equipment for customers simply to sell equipment for profit. This has caused the increase in beneficiation investment and cost, and has no effect on improving the beneficiation effect.

In order to avoid this situation and create greater economic benefits for customers, Gongyi Forui Machinery Factory will introduce to customers in detail the pyrite beneficiation and the configuration of the pyrite beneficiation equipment. help.

Pyrite Beneficiation Process

The beneficiation of pyrite is mainly completed by gravity beneficiation methods and equipment. The gravity beneficiation of pyrite is based on the difference in specific gravity between pyrite and gangue. The specific gravity of pyrite is 4.9-5.2, and the specific gravity of gangue associated with pyrite is not more than 3.0. Therefore, there is a very obvious difference in specific gravity between useful minerals and gangue, which is easy to process minerals. Moreover, the particle size of pyrite embedded in the ore is generally relatively coarse, and a higher degree of monomer dissociation can be achieved by crushing or finely crushing, and then entering the gravity beneficiation process to produce high-grade pyrite. Next, let’s take a closer look through several sets of pyrite beneficiation production lines designed and built by Fory Machinery.

1. Pyrite Beneficiation Process

This pyrite beneficiation process adopts jaw crusher for coarse crushing, rod mill for fine crushing, trapezoidal jig gravity beneficiation, dewatering screen dewatering and other processes and equipment configuration. It is used to extract pyrite from pyrite ore. The pyrite ore has a relatively high hardness and a sulfur content of 15-20%. Through the processing of the pyrite production line, the pyrite concentrate contains 42.2% sulfur and is recycled The rate is more than 90%, and all beneficiation indicators have been recognized by customers.

2. Coal-based Pyrite Beneficiation Process

This pyrite beneficiation production line is to extract pyrite from coal gangue. It uses jaw crusher for coarse crushing, hammer crusher for fine crushing, trapezoidal jig gravity beneficiation, linear dewatering screen dewatering process and equipment configuration. It mainly completes the task of extracting pyrite from high-sulfur coal gangue. The gangue contains 20-25% sulfur, the jig gravity beneficiation concentrate contains 38-42% sulfur, and the recovery rate is over 90%. Various beneficiation indicators All have been recognized by customers.

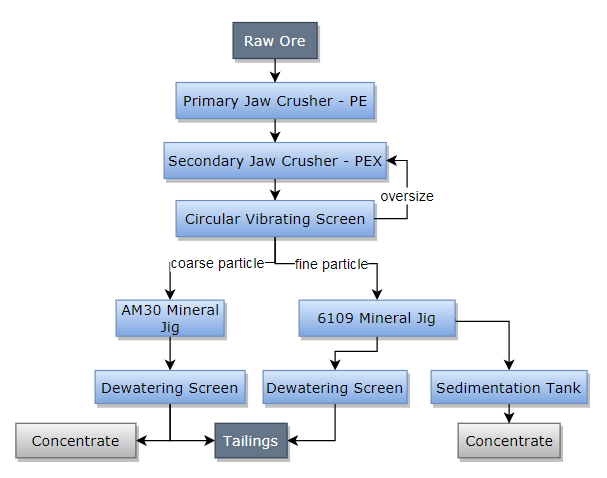

3. The Beneficiation Process of Coarse-grained Pyrite for Counterweight

Pyrite has a relatively large proportion and can be used in counterweight industries in addition to military industry, agriculture, chemical industry and other industries. Coarse-grained pyrite is a high-quality counterweight material. Most of the pyrites in Anhui, China are coarse-grained pyrite, which is very suitable for the production of pyrite for counterweight.

This pyrite beneficiation production line adopts the technology and equipment configuration of jaw crusher for coarse crushing, circular vibrating screen, large particle jig and down-moving jig for gravity beneficiation, and dehydration by dewatering screen. It has completed the task of extracting coarse-grained pyrite from the ore and recovering fine particle pyrite concentrate at the same time. The proportion of raw ore is 3.6, the proportion of concentrate is 4.4-4.6, and the recovery rate is over 90%. The beneficiation index fully meets the requirements of customers.

4. Fine-grained Pyrite Concentrate Beneficiation Process

The fine-grained pyrite concentrate production line refers to the production line for the production of fine-grained pyrite concentrate. Whether the raw material is ore or coal gangue, fine-grained pyrite concentrate is obtained after processing by this ore-dressing production line. The fine-grained pyrite concentrate is used in agriculture and sulfuric acid industries. This beneficiation production line adopts the process configuration of jaw crusher for coarse crushing, rod mill for fine crushing, jigging machine for gravity beneficiation, and dewatering by dewatering screen. It has completed the task of extracting fine-grained pyrite concentrate from ore and coal gangue. The beneficiation index is good and has been well received by customers.

In fact, there is another method for beneficiation of pyrite, which is flotation. The use of flotation to produce pyrite has a high beneficiation index, but the equipment investment is huge, the production cost is high, and it is also harmful to the environment. Therefore, in recent years, the application of flotation in the field of pyrite beneficiation has become less and less. With the rapid development of gravity beneficiation equipment and technology, gravity beneficiation has a tendency to completely replace flotation.

4. Pyrite Beneficiation Projects

Gongyi Forui Machinery Factory is a professional manufacturer of mineral jigs, magnetic separators, vibrating screens, dewatering screens, and other beneficiation equipment. We have a professional beneficiation test platform, which can carry out beneficiation experiments for customers free of charge, and design the beneficiation process and equipment configuration according to the actual situation. Welcome customers to visit our factory and purchase equipment.

If you need equipment quotation and process flow, please feel free to Contact Us:

- Whatsapp: +8618026978087

- Email: asa.guo@foruimining.com

Subscribe to my channel

Subscribe to my channel