Today we did an experiment to recover iron from steel slag for customers in Turkey. The result of the experiment was very good. We recovered 95% of the iron in the steel slag. Do you want to know how we do it? Please check this video.

1. Overview

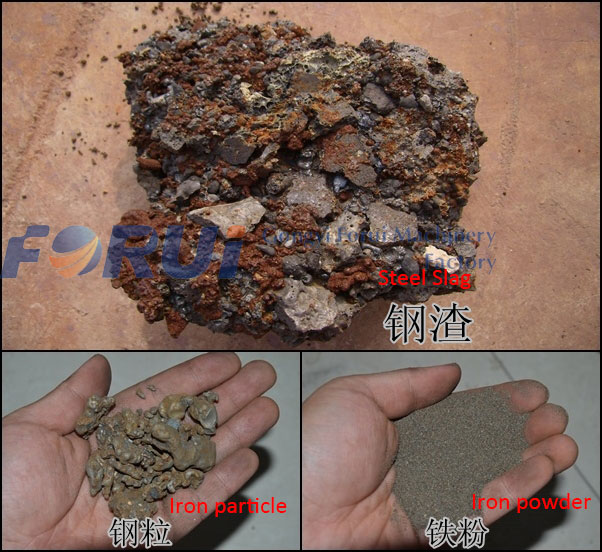

The utilization value of steel slag is that steel slag contains a certain amount of steel particles and iron powder, that is to say, recycling steel particles and iron powder is the main way to use steel slag. So how to recycle steel particles and iron powder? Gongyi Forui Machinery Factory will next share the steel slag treatment process.

2. Steel Slag Recovery Process

Under normal circumstances, the treatment process of steel slag is mainly divided into three steps: crushing, grinding, and beneficiation.

2.1 Steel Slag Crushing Process

The steel slag produced by the steel plant is irregular and uneven, and steel particles, iron powder, and slag are all mixed together. The steel slag must be broken up through crushing and grinding before it can be sorted. Because the steel slag is mostly lumpy and the hardness is relatively large, the steel slag is coarsely crushed by a jaw crusher with a large crushing ratio and durability.

If the size of the coarsely crushed steel slag can reach 10mm or less, it can be directly sent to the ball mill for grinding. Otherwise, the coarsely crushed steel slag needs to be sent to the fine-grain jaw crusher for the second crushing.

2.2 The Grinding Process of the Ball Mill

The steel slag cannot be completely broken by a crusher alone, and a ball mill is also needed. After crushing, the steel slag below 10mm is directly sent to the ball mill to grind the ore, and the connection structure between the steel slag, iron powder, and slag is broken up after sufficient grinding, so as to proceed to the next step of sorting.

The ball mill produced by our factory is equipped with a screen cage at the end, so that when the material comes out of the ball mill, the screen cage directly separates the granular steel particles from the fine iron powder and slag, eliminating the need for vibrating screens and reducing customers The investment cost.

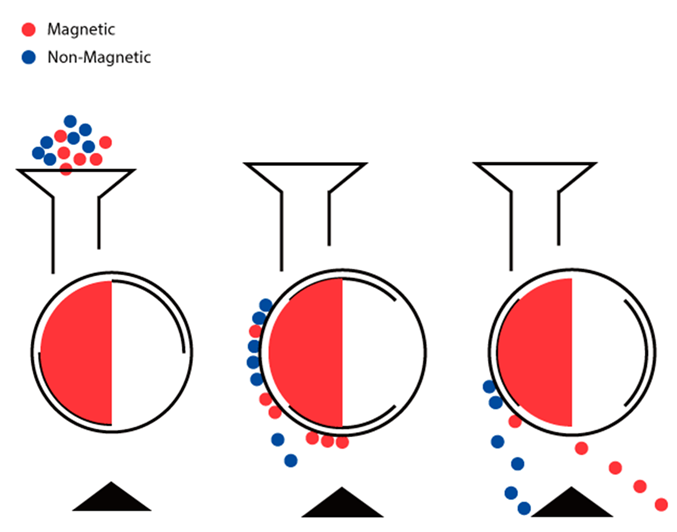

2.3 Extraction of Steel Grain (Particle Steel) and Iron Powder

Since both steel particles and iron powder are magnetic, the equipment for separating and extracting steel particles and iron powder is a magnetic separator. The ball mill produced by our factory has a screen cage device at the end, and the steel particles screened out can be directly separated by a belt-type magnetic separator. The finer materials flow into the wet magnetic separator for iron selection along the chute, thereby completing the extraction of steel particles and iron powder.

After sorting, the price of the steel grains is higher, which is the profit point of the entire production line. The selected iron powder has a lower price, but a larger quantity, which can offset the cost of workers, as well as water and electricity. The waste slag after sorting iron powder can be sold to cement factories and brick factories as raw materials or additives.

The entire production line has completed the complete recycling of steel slag, which not only achieved profitability but also played a positive role in protecting the environment. Therefore, the recycling and utilization of steel slag are strongly supported by the state.

3. Advantages of Our Steel Slag Recovery Process

3.1 The wet steel slag treatment process adopted by our factory can not only recover steel particles in steel slag but also recover iron fine powder. Almost all the steel slag has been used.

3.2 The use of the grinding head screen has been able to meet the separation of steel particles and waste slag, saving the investment of a vibrating screen.

3.3 The wet steel slag treatment process will not generate dust, and avoid the pollution of the dry powder to the environment.

3.4 Steel slag treatment customer site

Gongyi Forui Machinery Factory is a high-quality enterprise specializing in the production of beneficiation equipment. Over the years, it has produced gravity beneficiation, magnetic separation, flotation, and other beneficiation equipment, and has accumulated a lot of practical experience. Forui Machinery is involved in lead-zinc ore, gold ore, fluorite, barite, pyrite, hematite, limonite, magnetite, manganese ore, antimony ore, tungsten ore, tin ore, celestite, etc. In the field of beneficiation of a variety of minerals, fruitful results have been achieved.

If you need equipment quotation and process flow, please feel free to Contact Us