Minerals and Resources

There are about 130 kinds of minerals containing tantalum and niobium in nature, of which there are about 80 kinds of tantalum and niobium minerals. In addition, part of tantalum and niobium exists in the form of impurities in ilmenite, perovskite, rutile, cassiterite, wolframite, and sphene. Tantalum-niobium deposits are divided into five categories: magmatic deposits, pegmatite deposits, gas-forming hydrothermal deposits, contact auto-metamorphic deposits, and exogenous deposits.

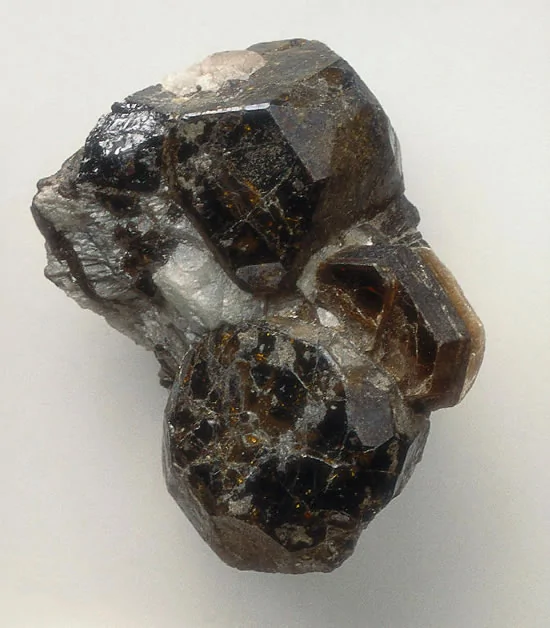

Tantalum-niobium ore types can be divided into three categories: tantalite-niobium iron ore, pyrochlore, and other tantalum-niobium ore. Tantalum-niobium deposits are widely distributed, including Brazil, the former Soviet Union, China, Canada, the United States, Nigeria, Australia, Zaire, Kenya, Tanzania, Uganda, Malaysia, Thailand, etc.

The main producers of tantalum and niobium concentrates are Canada, Brazil, Australia, Zaire, the former Soviet Union, and Thailand. The United States and Japan are the main consumers of tantalum and niobium.

Beneficiation Process

The mineral composition of tantalum-niobium ore is complex, the composition is unstable, and the content of valuable components is low, so its beneficiation process is more complicated. Usually, the beneficiation process of tantalum-niobium ore consists of two parts: roughing and beneficiation. Different types of ore deposits contain different types of tantalum and niobium minerals, so their beneficiation process is also different.

Beneficiation Process of Primary Tantalite and Fine Spar

Tantalite and columbite in this type of ore are mostly symbiotic with beryl, spodumene, and cassiterite. Rough separation mainly adopts the process of a multi-stage grinding and multi-stage gravity beneficiation. For some ore roughing, the process of gravity beneficiation-flotation-gravity beneficiation or gravity beneficiation-flotation is also adopted.

The selection of tantalum-niobium ore mostly adopts a combined process. According to the different types of tantalum-niobium ore and its associated minerals, they usually use a combination of magnetic separation, gravity separation, flotation, flotation-gravity separation, electric separation, chemical separation, and other methods. If there is a lot of mud in the ore, desliming treatment should be carried out first. The fine spar rich in tantalum is mostly purified by the flotation process because of its fine grain size.

Tantalite-niobium Iron Ore Beneficiation Process

The various minerals in this type of ore have been basic monomer dissociation, the useful mineral density is greater than 4, and some minerals are magnetic. The gravity beneficiation process is often used for roughing, and the obtained coarse concentrate is mainly selected by magnetic separation-gravity beneficiation, magnetic separation-electric separation, and flotation combined process.

Pyrochlore Beneficiation Process

There are two main types of pyrochlore: carbonatite and pegmatite. Carbonatite pyrochlore deposits are large in scale and high in niobium, which is an important deposit type. Due to the different types and contents of minerals in the ore, two processes are adopted: gravity beneficiation, magnetic separation-flotation, and roasting and magnetic separation. The rough separation of pegmatite pyrochlore adopts a multi-stage crushing and graded gravity beneficiation process. The beneficiation process mostly uses magnetic separation to remove tailings, and flotation obtains pyrochlore concentrate. Sometimes electric separation or flotation is used to remove zircon in the coarse concentrate.

Gongyi Forui Machinery Factory is a high-quality enterprise specializing in the production of beneficiation equipment. Over the years, it has produced gravity beneficiation, magnetic separation, flotation, and other beneficiation equipment, and has accumulated a lot of practical experience. Forui Machinery is involved in lead-zinc ore, gold ore, fluorite, barite, pyrite, hematite, limonite, magnetite, manganese ore, antimony ore, tungsten ore, tin ore, celestite, etc. In the field of beneficiation of a variety of minerals, fruitful results have been achieved.

If you need equipment quotation and process flow, please feel free to Contact Us