WHAT ARE THE TYPES OF CHROME ORE?

According to the content of chromium spinel:

- Dense lumps.

- Densely disseminated.

- Moderately disseminated.

- Sparse disseminated ore.

According to the chemical composition of chromium ore, it is divided into:

- High-chromium chromium iron ore, containing Cr2O3>46%, Cr/Fe>2.

- High-iron chromite ore, containing Cr2O340%~46%, Cr/Fe>1.5~2.

- High-aluminum chromite ore, Al2O3>20%, Cr2O3+Al2O3>60%.

According to the Cr2O3 grade of chrome ore and the ratio of ferrochrome:

- Chromium-rich ore Cr2O3≥32%, Cr2O3/FeO>2.5.

- Depleted chromium ore Cr2O312%~32%.

Different industrial uses of chromium ore have different industrial requirements. According to the industrial use of chrome ore, it is divided into:

- Metallurgical grade

- Refractory grade

- Chemical grade

- Cast stone grade

The allowable impurity content of primary chromium-rich ore in my country is: SiO2≤8%, P≤0.07%, S<0.05%. The placer chrome ore requires Cr2O3≥3%, regardless of rich ore and poor ore.

WHAT ARE THE BENEFICIATION METHODS FOR CHROME ORE?

Common chromium spinel minerals in chromium ore in my country include chromite, aluminum chromite, and chromium-rich spinel. Gangue minerals mainly include olivine, serpentine, and pyroxene. Sometimes a small amount of vanadium, nickel, cobalt, and platinum group elements are associated.

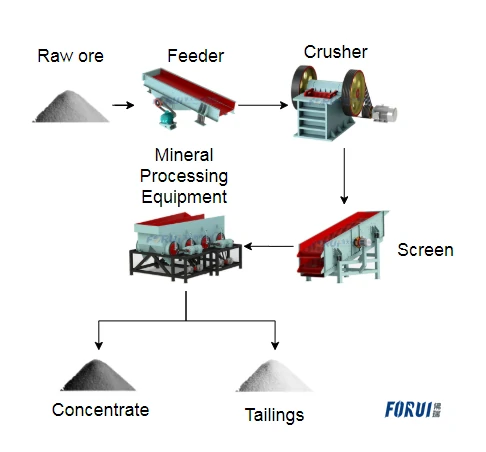

The beneficiation of chromite ore mainly adopts the gravity beneficiation method. In actual production, shakers and jigs are often used for the beneficiation of chromium ore. Sometimes the concentrate obtained by gravity beneficiation needs to be beneficiated by weak magnetic separation or strong magnetic separation to further improve the grade of chromium concentrate and the ratio of chromium to iron.

Chromium spinel is an ore with high iron content or dense symbiosis with magnetite. In the concentrate obtained after beneficiation, the chromium grade and the ferrochrome ratio are both low. It can be considered as an ingredient for the production of ferrochrome by pyrolysis, or Use hydrometallurgical treatment. For example, sodium dichromate method, chromium hydroxide method, reduction corrosion method, chlorination roasting acid leaching, or electrolysis method. Hydrometallurgical treatment of low-grade chromite concentrate has been a production practice.

The associated platinum group elements in chromite ore, such as sulfide, arsenide, or sulfur arsenide, can be recovered by flotation. The olivine and serpentine in the ore can be comprehensively recycled for use in the production of refractory materials, calcium magnesium phosphate fertilizer, or diabase cast stone.

Gongyi Forui Machinery Factory is a high-quality enterprise specializing in the production of beneficiation equipment. Over the years, it has produced gravity beneficiation, magnetic separation, flotation, and other beneficiation equipment, and has accumulated a lot of practical experience. Forui Machinery is involved in the lead-zinc ore, gold ore, fluorite, barite, pyrite, hematite, limonite, magnetite, manganese ore, antimony ore, tungsten ore, tin ore, celestite, etc. In the field of beneficiation of a variety of minerals, fruitful results have been achieved.

If you need equipment quotation and process flow, please feel free to Contact Us