Overview

Xinjiang has a vast territory and rich mineral resources. Forui Machinery has successfully installed multiple placer gold beneficiation production lines in Xinjiang. Today we will share the production technology of placer gold beneficiation in Xinjiang.

It is relatively simple to extract gold from alluvial gold mines. Generally, good quality gold can be obtained through screening, gravity beneficiation and cleaning. However, the content of gold in placer gold mines is very limited. How can we ensure that the gold placer ore beneficiation production line produces higher returns? We need to adopt high-efficiency, energy-saving, large processing capacity and high recovery rate of alluvial gold beneficiation technology and alluvial gold beneficiation equipment. The following is the gold beneficiation process designed by Forui Machinery for customers in Xinjiang:

Beneficiation Method of Alluvial Gold Ore

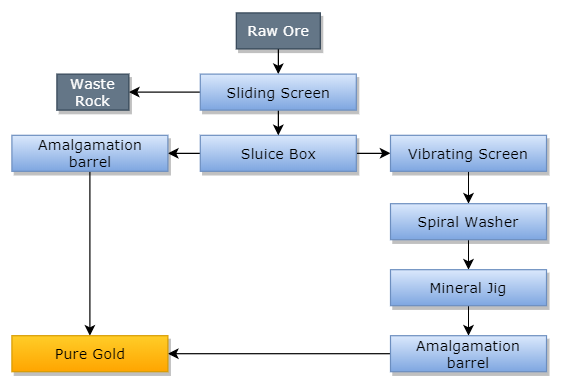

The process adopts the process and equipment configuration of sluice box roughing, jig scavenging, and amalgamation barrel beneficiation. While ensuring a large processing capacity, a high recovery rate must be ensured. Only in this way can low-grade alluvial gold be guaranteed. Economic benefits of ore dressing.

The average gold content of this placer gold mine does not exceed 0.5g/ton, which is a low-grade placer gold mine. Therefore, a large beneficiation processing capacity and recovery rate must be ensured to have considerable economic benefits. For this reason, we designed a sluice box + jig + amalgamation process for our customers.

First of all, the alluvial gold mine is fed into the sluice box through a loader to screen out large pieces of waste rock to prevent large pieces of waste rock from entering the sluice box and affecting the normal operation of the sluice box. After screening large pieces of waste rock, the fine sand enters the sluice box. The biggest feature of the sluice box is its large processing capacity and low beneficiation cost. The sluice box is cleaned every 4 hours, and the crude concentrate obtained from the sluice box is purified by the amalgamation method to obtain gold.

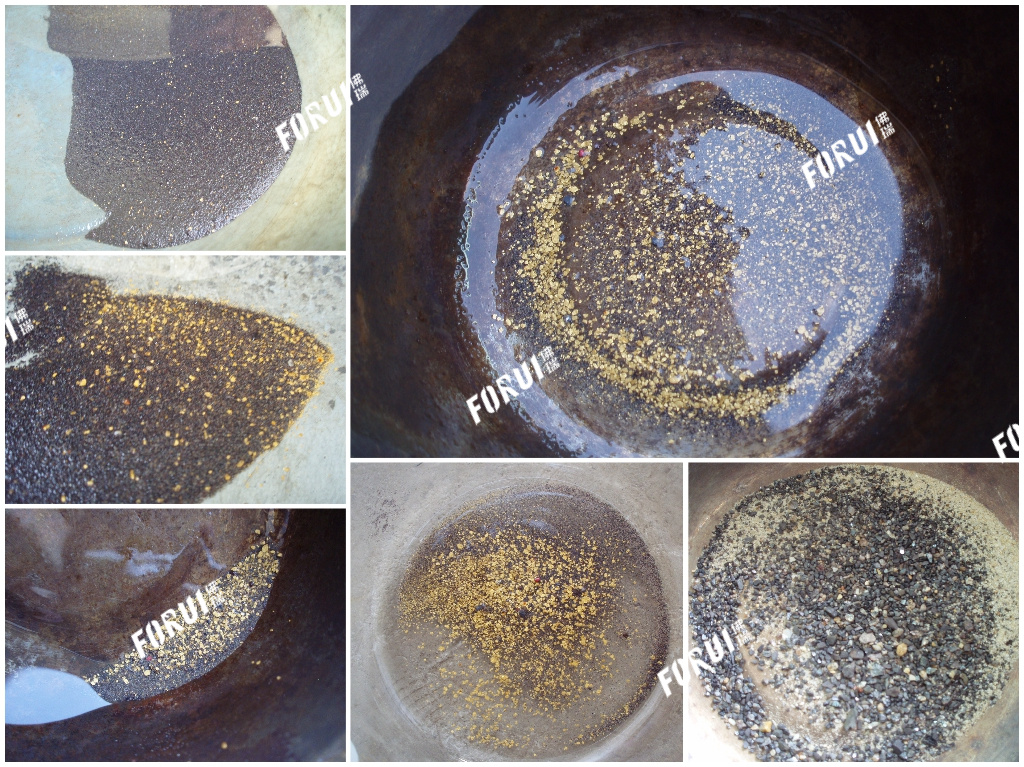

The tailings of the sluice box enter the vibrating screen for screening, and all the minerals larger than 6mm are screened out to ensure that the size of the mineral particles is within the effective feed size range of the jig. The function of the jig machine to sweep the tailings of the sluice box is to improve the recovery rate of the whole process and to recover the fine-grained gold and flake gold lost in the sluice box as much as possible. The concentrate of the jig is mixed with an amalgamation cylinder to extract gold. The recovery rate of the amalgamation cylinder is usually higher than 95%, which is one of the traditional and practical gold extraction equipment.

Gongyi Forui Machinery Factory is a professional manufacturer of beneficiation equipment. Our factory has designed alluvial gold beneficiation technology and equipment configuration for multiple alluvial gold beneficiation plants and has a complete test platform. It can conduct beneficiation tests and design processes for customers free of charge.

If you need equipment quotation and process flow, please feel free to Contact Us