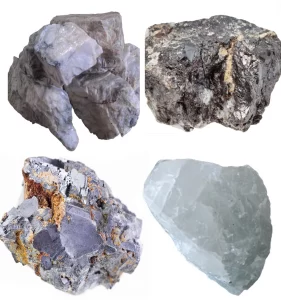

Cost of a Fluorspar Flotation Plant: A Case of a 200t/h Fluorite Processing plant

Explore the cost breakdown of fluorite ore flotation, detailing equipment, reagents, and operational expenses. Calculate daily costs and per-ton concentrate production for efficient cost management.